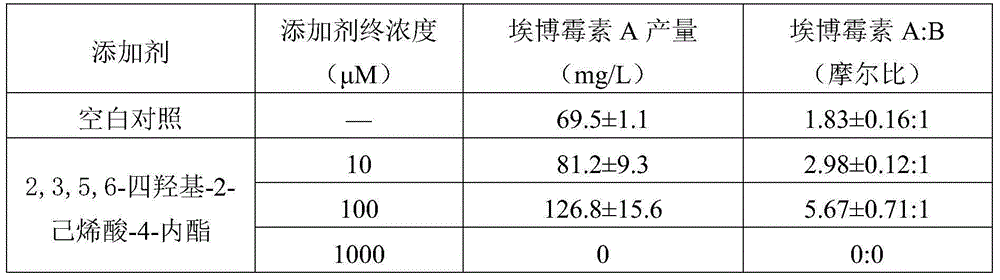

Fermentation additive capable of changing generation rate of epothilone compound and improving yield of epothilone A

A technology of epothilones and additives, which is applied in the field of fermentation and preparation of antineoplastic drugs, can solve the problems of changing the product ratio, changing the biological ratio of epothilones, etc., and achieve the effects of increasing production, good water solubility, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Selection of fermentation strains: Sorangium cellulosum So0157-2 among the myxobacteria strains.

[0044] (2) Activation of strains: the above strains were inoculated on a solid plate medium, cultured at 30° C. for 7 days, then inoculated into a liquid medium, and cultured at 30° C. at 200 rpm for 5 days.

[0045] Then pour the obtained bacterial solution into a spinner bottle containing glass beads and disperse for 2 minutes, and set aside.

[0046] in,

[0047] The composition of the solid plate culture medium is: KNO 3 0.5g / L, Na 2 HPO 4 0.25g / L, MgSO 4 ·7H 2 O1g / L, FeCl 3 0.01g / L, trace element solution 1ml / L, agar 15g / L, pH7.2 (after pouring the plate to solidify, paste a 1.5×1.5cm square filter paper piece).

[0048] The composition of described liquid medium is: potato starch 8g / L, soybean peptone 2g / L, glucose 2g / L, yeast powder 2g / L, MgSO 4 1g / L, CaCl 2 1g / L, EDTA-Fe3+1ml / L, trace element solution 1.0ml / L, pH7.2.

[0049] The trace element solutio...

Embodiment 2

[0064] (1) Selection of fermentation strains: Sorangium cellulosum So0157-2 among the myxobacteria strains.

[0065] (2) Activation of strains: the above strains were inoculated on a solid plate medium, cultured at 30° C. for 7 days, then inoculated into a liquid medium, and cultured at 30° C. at 200 rpm for 5 days.

[0066] Then pour the obtained bacterial solution into a spinner bottle containing glass beads and disperse for 2 minutes, and set aside.

[0067] in,

[0068] The composition of the solid plate culture medium is: KNO 3 0.5g / L, Na 2 HPO 4 0.25g / L, MgSO 4 ·7H 2 O1g / L, FeCl 3 0.01g / L, trace element solution 1ml / L, agar 15g / L, pH7.2 (after pouring the plate to solidify, paste a 1.5×1.5cm square filter paper piece).

[0069] The composition of described liquid medium is: potato starch 8g / L, soybean peptone 2g / L, glucose 2g / L, yeast powder 2g / L, MgSO 4 1g / L, CaCl 2 1g / L, EDTA-Fe3+1ml / L, trace element solution 1.0ml / L, pH7.2.

[0070] The trace element solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com