Intelligent temperature-control electrical tracing heat insulating formwork and electrical tracing method

A technology of intelligent temperature control and thermal insulation formwork, which is applied in the field of engineering and construction, can solve the problems of non-reusable use, reduction of contact area, loss of thermal insulation function, etc., and achieve the effects of saving labor costs, high degree of intelligent control, and high efficiency of heat energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

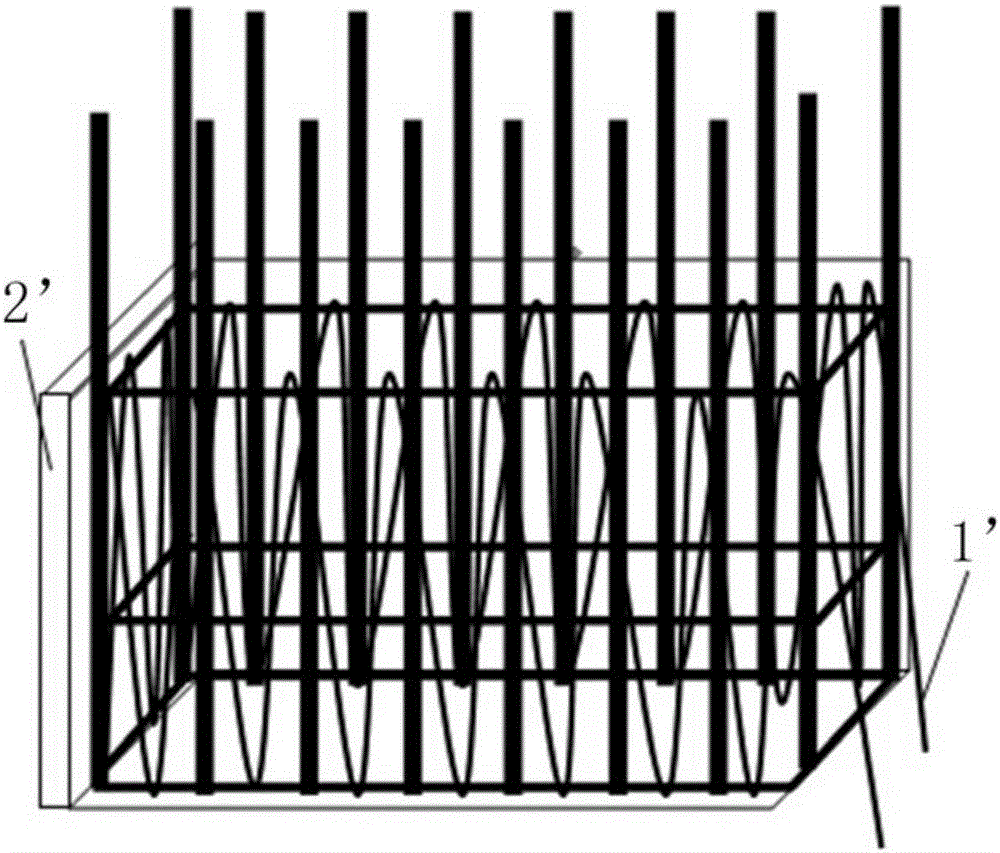

[0049] Such as Figure 7 As shown, when building bridge piers (elevated railways, elevated roads, etc.) in outdoor construction, especially in cold winter, when the temperature is at -19°C or below, thermal insulation measures need to be taken. This embodiment is exactly when the bridge piers are built. Intelligent temperature control electric heat tracing insulation template. After the electric heat tracing insulation formwork is installed according to the construction (design) requirements of the bridge pier, the temperature sensor 12 is placed in the middle of the concrete space to be poured. Generally, the shape of the bridge pier is cylindrical or square, so the temperature sensor 12 is generally placed In the center of the cross-section of the pier, of course, according to the actual needs such as the height and quantity of the pier, multiple temperature sensors 12 can be provided, and electric heat tracing can be carried out according to different regions or individuals...

Embodiment 2

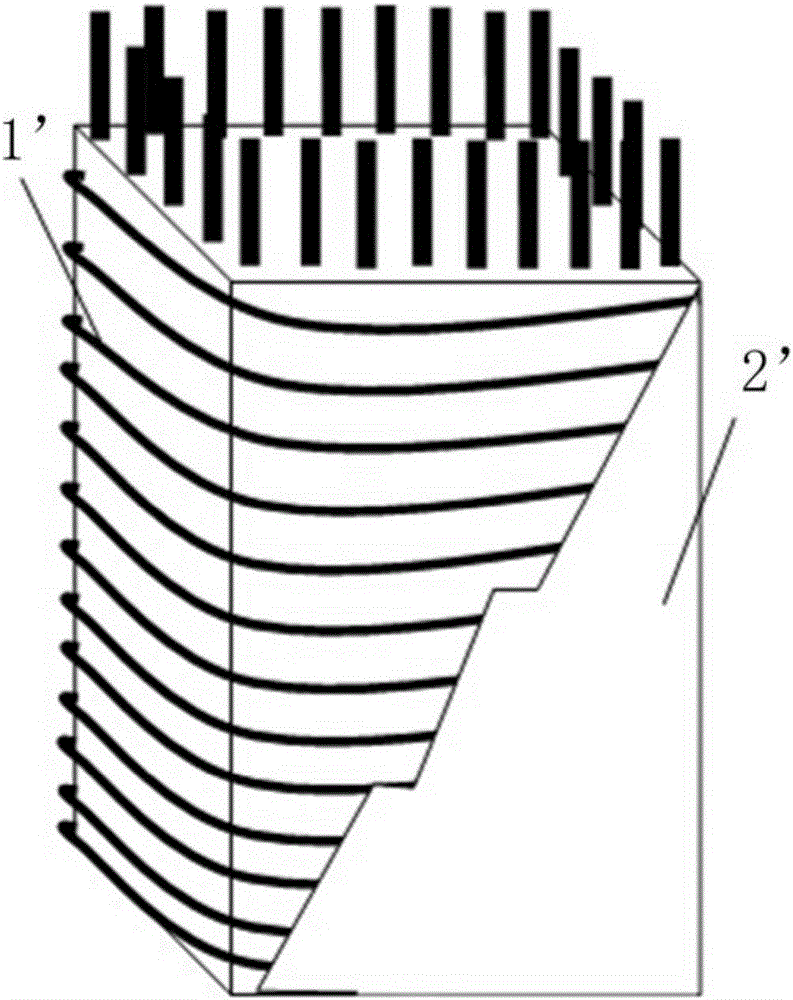

[0053] Such as Figure 8 As shown, when a bridge needs to be built, according to different technical requirements and construction conditions, generally, there are two construction methods for bridges, one is to make in the prefabricated bridge yard, and the other is to make in the construction site. The first way is to make it in the prefabricated bridge yard, and then transport the finished bridge to the construction site for installation; the second way is to pour bridge concrete on site, and then form the bridge. Both methods require heating, insulation and curing of the concrete poured on the bridge during winter construction.

[0054] When making a bridge, after the electric heat tracing insulation formwork is installed according to the construction (design) requirements of the bridge, multiple temperature sensors 12 can be set according to factors such as the volume and shape of the concrete parts and the parts prone to heat loss. For example, a bridge with a larger vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com