Gas roller way kiln

A technology of roller table and kiln, which is applied in the field of sintering equipment to achieve the effects of small local temperature difference, stable product firing curve and protection of burners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

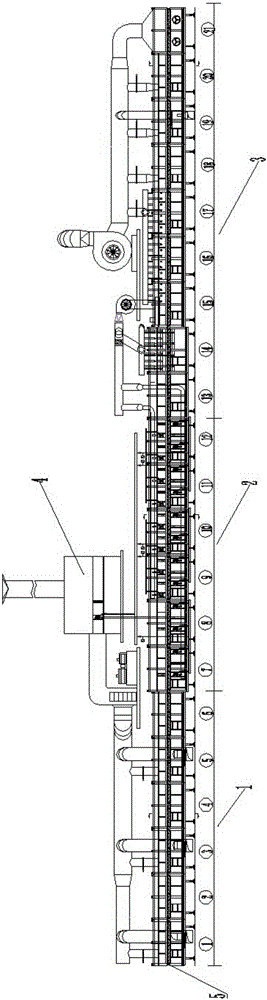

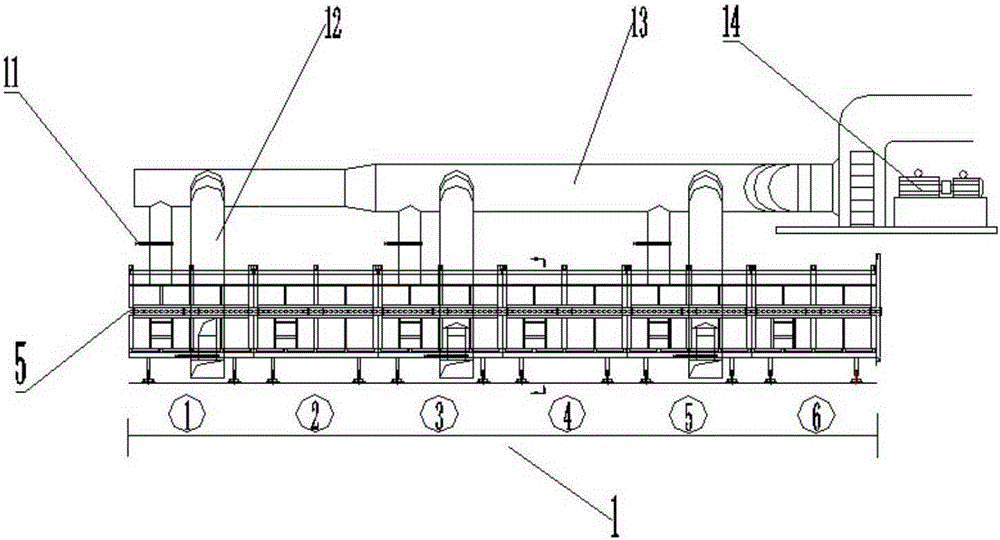

[0023] The gas-fired roller kiln of this embodiment includes a kiln body, and the kiln body is divided into 21 units. The units ①-⑥ are the preheating section 1. The smoke exhaust branch pipe 12, the kiln body is provided with the smoke exhaust port connected with the smoke exhaust branch pipe 12 which is set up and down staggered; 13 is provided with exhaust fan 14;

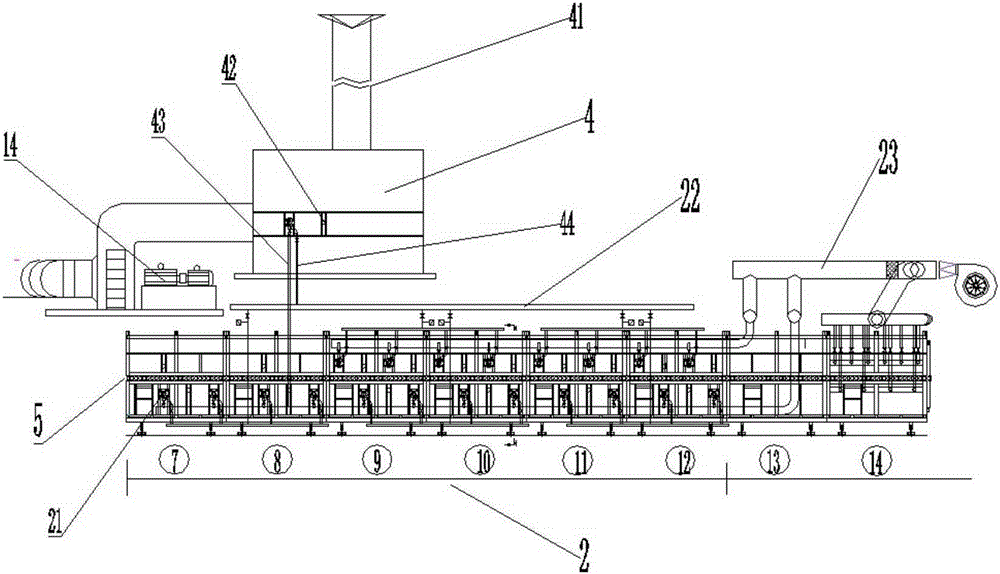

[0024] The unit is the firing section 2, and a set of burners 21 are provided under the inner roller table of the units ⑦ and ⑧; In the unit, there are one set of burners 21 above and below the roller table 5 of each unit, a total of 8 sets; 9 sets of burners 21 are respectively connected to the PLC controller; the burners 21 are connected to the gas pipe one 22, each One side of the burner 21 is provided with a combustion-supporting air duct, and the combustion-supporting air duct is connected with the combustion-supporting fan 23;

[0025] The unit is cooling section 3, The unit is a transition unit; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com