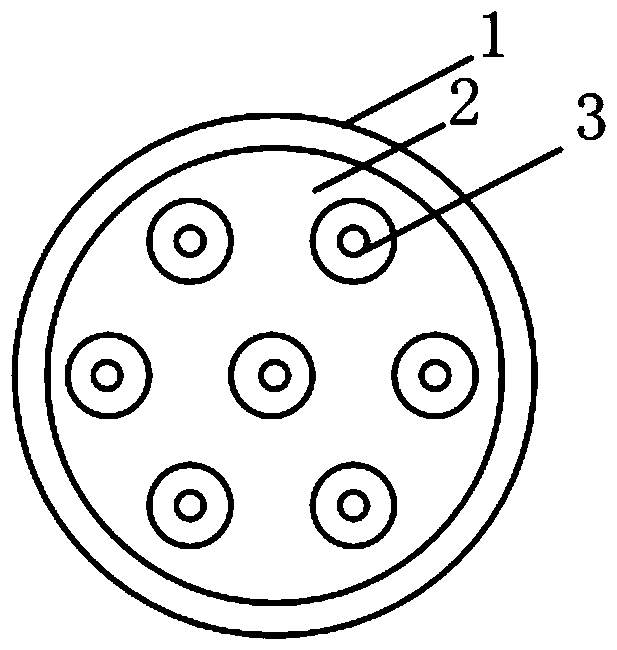

A preparation method of multi-core optical fiber coupler based on microhole processing

A multi-core fiber, micro-hole processing technology, applied in the coupling of optical waveguides, instruments, optics, etc., to achieve the effect of increasing return loss, easy processing, and unchanged process cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

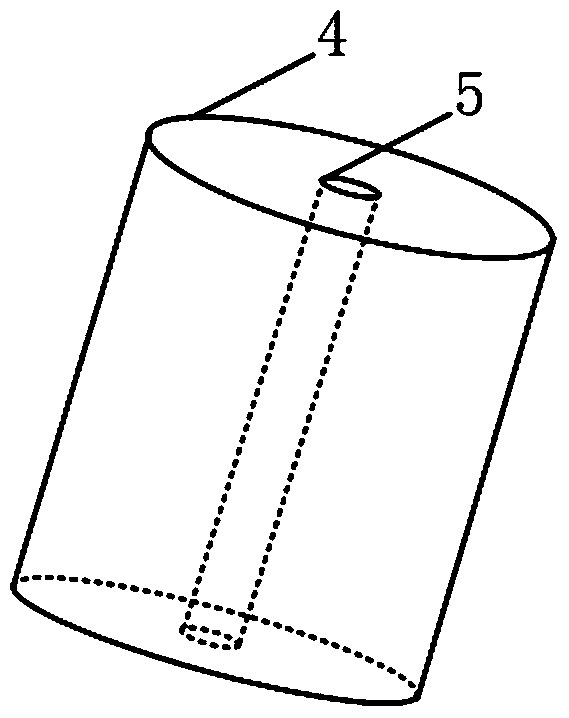

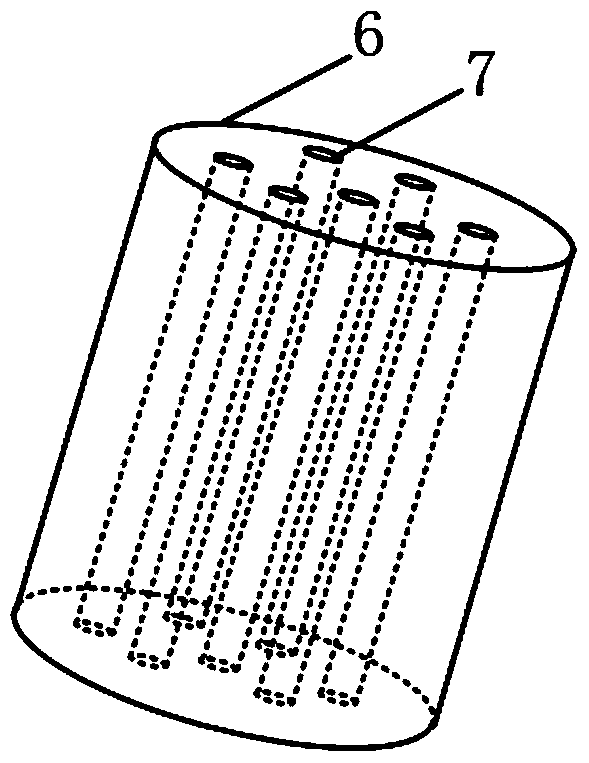

[0051] Embodiment 2 provides a kind of preferred multi-core optical fiber coupler preparation method based on microhole processing, such as Image 6 As shown, when step (4) prepares the seven-hole cylindrical quartz glass column 6, the position and diameter of the through hole are enlarged by K times, and K is a real number greater than 1;

[0052] When the processing accuracy of the through hole position is ±3.0 microns, and K is 10, the laser micro-hole processing technology is used to process the through holes. K, i.e. 450 microns, such as Image 6 The front end of the middle drawer cone 22;

[0053] The quartz glass column 6 is heated by a hydrogen-oxygen flame, and the quartz glass column 6 is tapered through a tapering platform. The length of the tapered area 21 is 5 to 20 mm, so that the diameter of the through hole in the end 20 of the tapered area formed after tapering is 20 mm. ~35 microns, and at the same time, the geometric distribution of the center of the throu...

Embodiment 3

[0054] Embodiment 3 provides a kind of preparation method of multi-core optical fiber coupler based on microhole processing. In step (7) and step (8), the multi-core optical fiber end 12 and the optical fiber bundle end 10 are respectively placed in a special fusion splicer, After the end faces of the fusion splicer are aligned, the end faces of the multi-core optical fiber end 12 and the fiber bundle end 10 are fused by arc discharge or electrothermal method;

[0055] According to the preparation method of the multi-core optical fiber coupler based on microhole processing provided by the present invention, the multi-core optical fiber is not limited to seven cores, the number of cores is at least 2, and there is no limit to the number of multi-fiber cores; the method is used to prepare the multi-core optical fiber coupler There is no restriction on the arrangement of the cores of the multi-core optical fiber, it is only necessary to arrange the cores of the multi-core optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com