A kind of fabrication method of columnar coaxial ring nanostructure

A nanostructure and manufacturing method technology, applied in the field of micro-nanostructure preparation, can solve the problems of high cost, reduced freedom of nano-imprinting, low efficiency, etc., and achieve the effects of high processing freedom and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

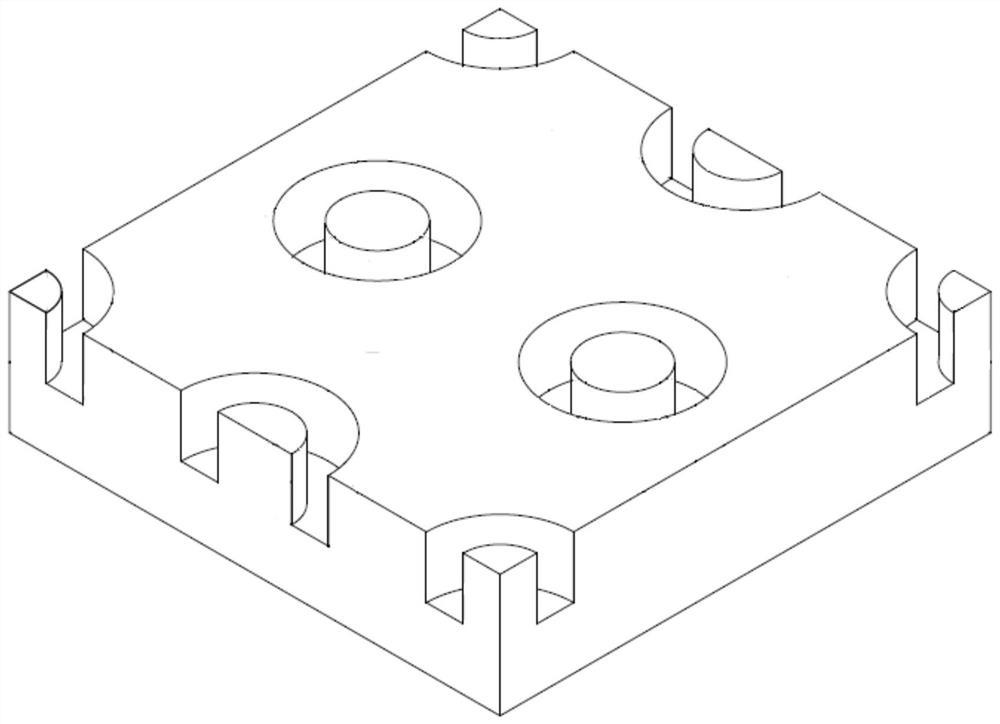

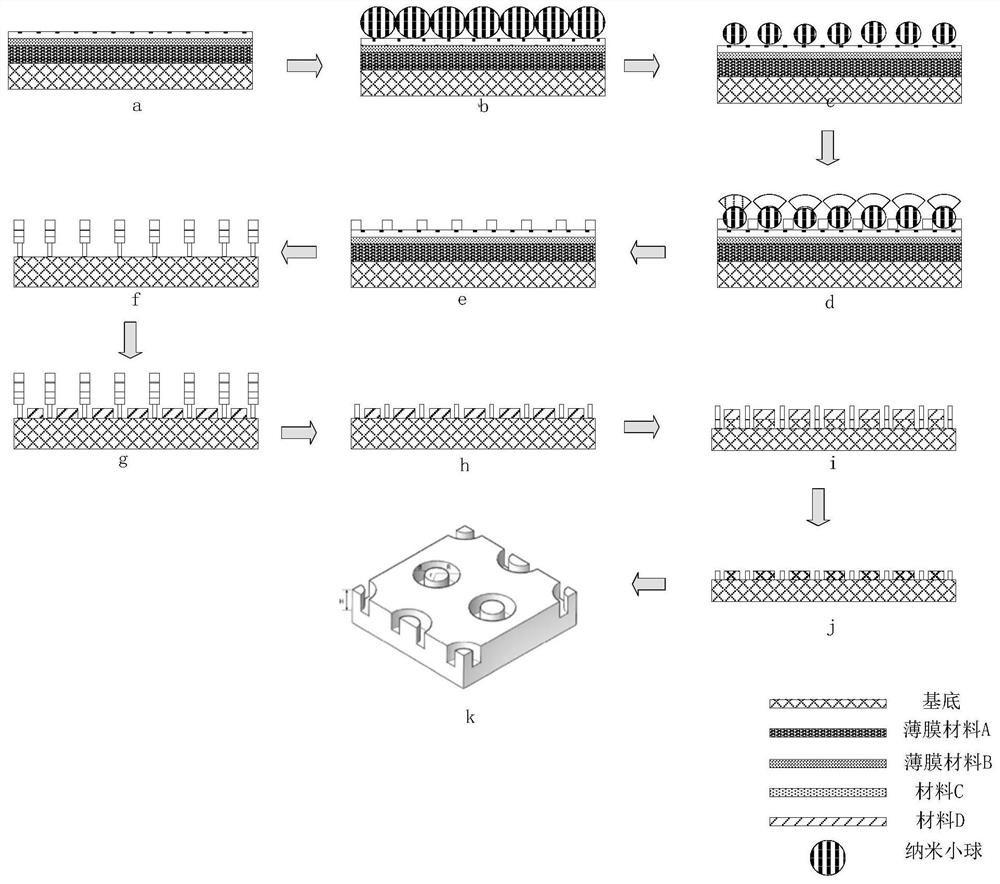

[0044] Figure 1-Figure 2 The manufacturing method of the shown columnar coaxial ring nanostructure, it may further comprise the steps:

[0045] (1) Film material A and film material B are coated successively on the silicon substrate, wherein, film material A is photoresist SU8 resistant to organic solvent corrosion, and film material B is positive resist Ar-P- 3740; and a layer of material C is plated on the upper surface of material B by physical deposition, and material C is titanium with a thickness of 30nm, such as figure 2 a.

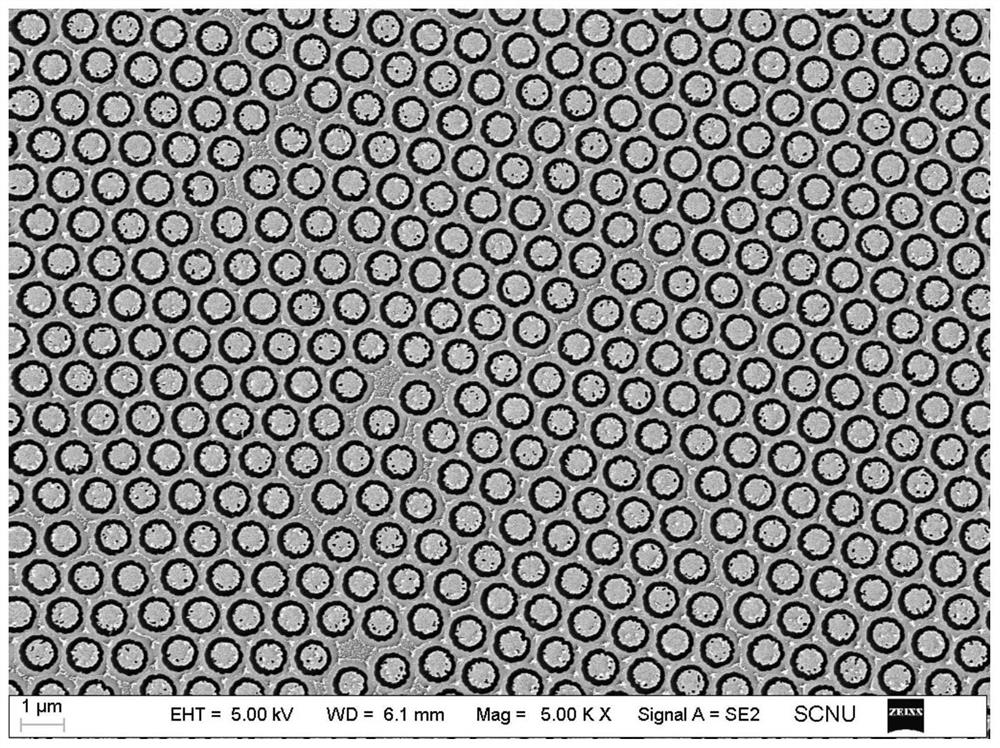

[0046] (2) the surface of the substrate after step (1) arranges a layer of polystyrene (PS) balls with a diameter of 1um by self-assembly method, such as figure 2 b, The size of the diameter of the spheres here will determine the period size of the final columnar coaxial nanostructure, or when the self-assembly process is controlled so that the spheres are randomly distributed, a randomly arranged columnar coaxial nanostructure can finally be ...

Embodiment 2

[0063] The difference between the manufacturing method of the columnar coaxial ring nanostructure in this embodiment and the embodiment 1 is that the substrate is a silicon dioxide substrate. Inductively Coupled Plasma Etching (ICP) etched silicon dioxide substrates using C 4 f 8 Mixed gas with He as the reaction gas. The specific etching process parameters are shown in Table 3:

[0064] Table 3 Process parameters of inductively coupled plasma etching (ICP) etching substrate silicon dioxide

[0065]

[0066] In this embodiment, the etching time of the base silicon dioxide is 190s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com