Method for reducing fissure rate of double-side diffused silicon wafers and shortening time required by diffusion technology

A diffusion process and double-sided diffusion technology, applied in the field of solar cells, can solve the problems of long time for entering and exiting the boat, reduced diffusion capacity, and increased production cost, and achieve the goals of reducing thermal stress, low fragmentation rate, and improving diffusion capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

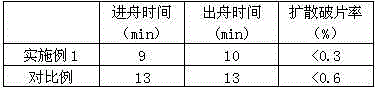

Examples

Embodiment 1

[0023] A method for reducing the double-sided diffusion fragmentation rate and shortening the diffusion process time, the specific steps are as follows:

[0024] (1) Fill the quartz boat with the cleaned and textured silicon wafers, place the quartz boat filled with silicon wafers on the silicon carbide paddle, and open the furnace door;

[0025] (2) The silicon carbide paddle runs at a speed of 700mm / min to the interface between the quartz boat and the furnace nozzle, and then runs to the front limit at a speed of 300mm / min;

[0026] (3) The silicon carbide paddle runs to the lower limit at a speed of 500mm / min;

[0027] (4) Run the empty propeller to the rear limit at the maximum speed required by the equipment of 1000mm / min, and close the furnace door;

[0028] (5) Open the furnace door, and run the empty propeller to the rear limit at the maximum speed 1000mm / min required by the equipment.

[0029] (6) The silicon carbide paddle runs to the upper limit at a speed of 500m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com