Quick-freezing freshness retaining method for bamboo shoots

A fresh-keeping method and technology of bamboo shoots, applied in the processing field of bamboo shoots, can solve problems such as high quality and safety risks, inability to maintain the appearance and freshness of fresh bamboo shoots, and loss of juice, so as to increase the glass transition temperature and prolong the high-quality frozen storage time , good crispness and color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

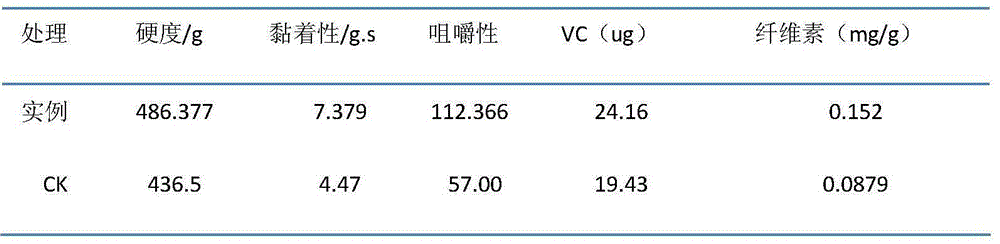

Embodiment 1

[0022] Embodiment 1. test material is the spring bamboo shoots of moso bamboo shoots gathered on a sunny day in April, and the bamboo shoots are selected to be plump and complete, fresh and clean, with good color and luster, no rot, no mildew, no peculiar smell, no fresh bamboo shoots that affect edible diseases and insect pests and mechanical damage . Within 2 to 8 hours after harvesting, put them in a cold storage at 1 to 5°C for 10 to 24 hours; the fresh bamboo shoots after precooling are shelled, washed, and cut into pieces; the processed bamboo shoots are added with 3 to 5% yellow The raw gum is soaked in a calcium chloride and trehalose compound embrittlement agent solution with a mass concentration of 5-60 g / L for 20-60 minutes; then the soaked bamboo shoot samples are measured for their partial glass transition temperature by a rapid scanning method. Drain the soaked bamboo shoots and put them in an environment of -40~-198°C for quick freezing to the glass transition t...

Embodiment 2

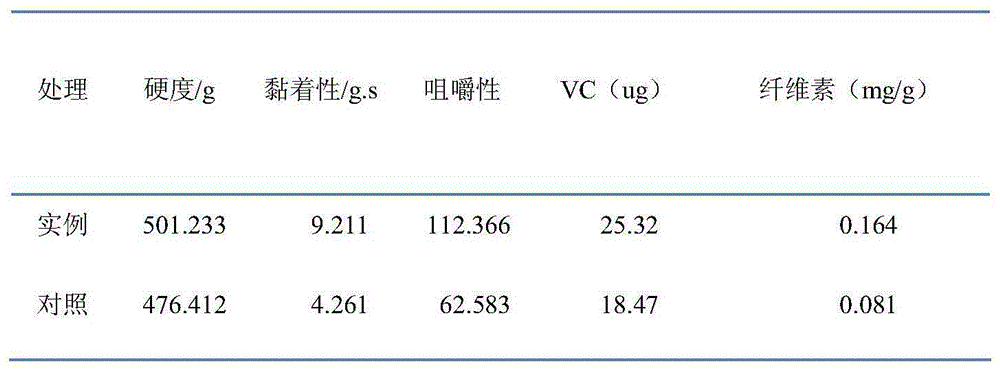

[0029] Example 2. The material for testing is the winter bamboo shoots of Phyllostachys pubescens harvested on a sunny day in January, and the bamboo shoots are selected to be plump and complete, fresh and clean, with good color, no rot, no mildew, no peculiar smell, no fresh bamboo shoots that affect edible diseases and insect pests and mechanical damage . Within 2 to 8 hours after harvesting, put them in a cold storage at 1 to 5°C to pre-cool for 10 to 24 hours; the fresh bamboo shoots after pre-cooling should be shelled, washed, and cut into pieces; Sodium methylcellulose, soaked in calcium chloride and trehalose compound brittle agent solution with a mass concentration of 5-60g / L for 20-60 minutes; then the glass transition temperature of the soaked bamboo shoot samples was measured by a rapid scanning method. Drain the soaked bamboo shoots and put them in an environment of -40 to -198°C for quick freezing to the glass transition temperature; put the fresh bamboo shoots th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com