Controller integrated electric driving system

An electric drive system and integrated controller technology, applied in the field of electric drive, can solve the problems of small output power of the motor system, occupy a large space, and connect the wiring harness with a large installation space, so as to increase the output power, save the occupied space, and increase the reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

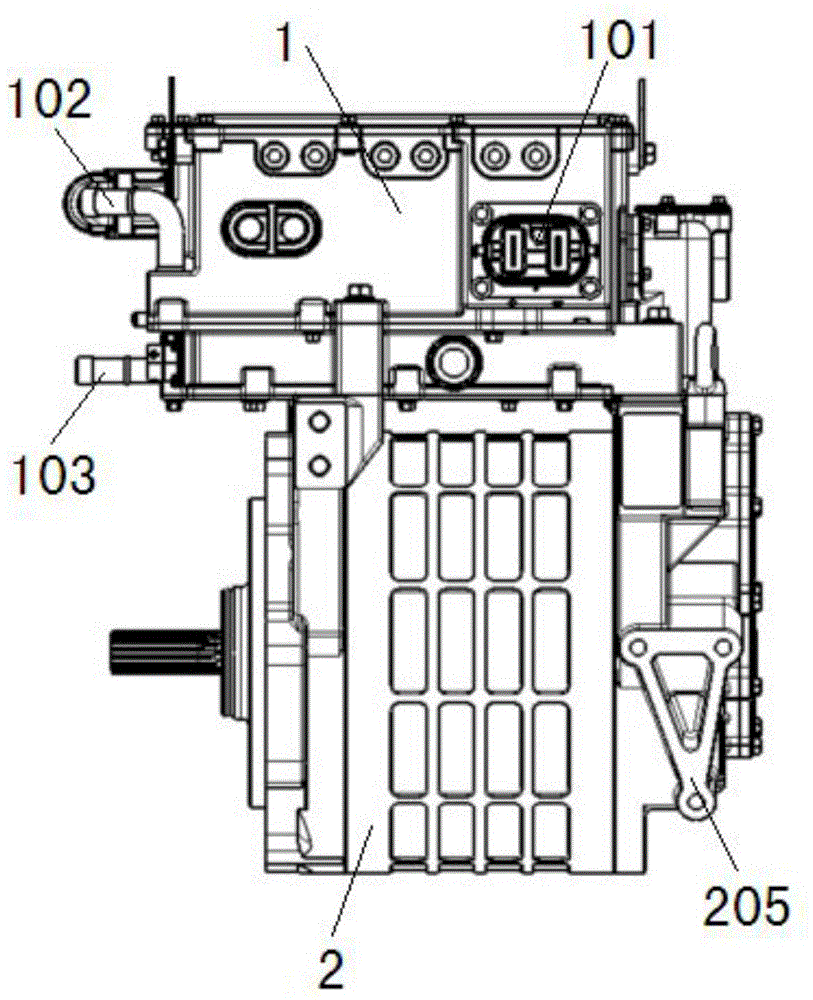

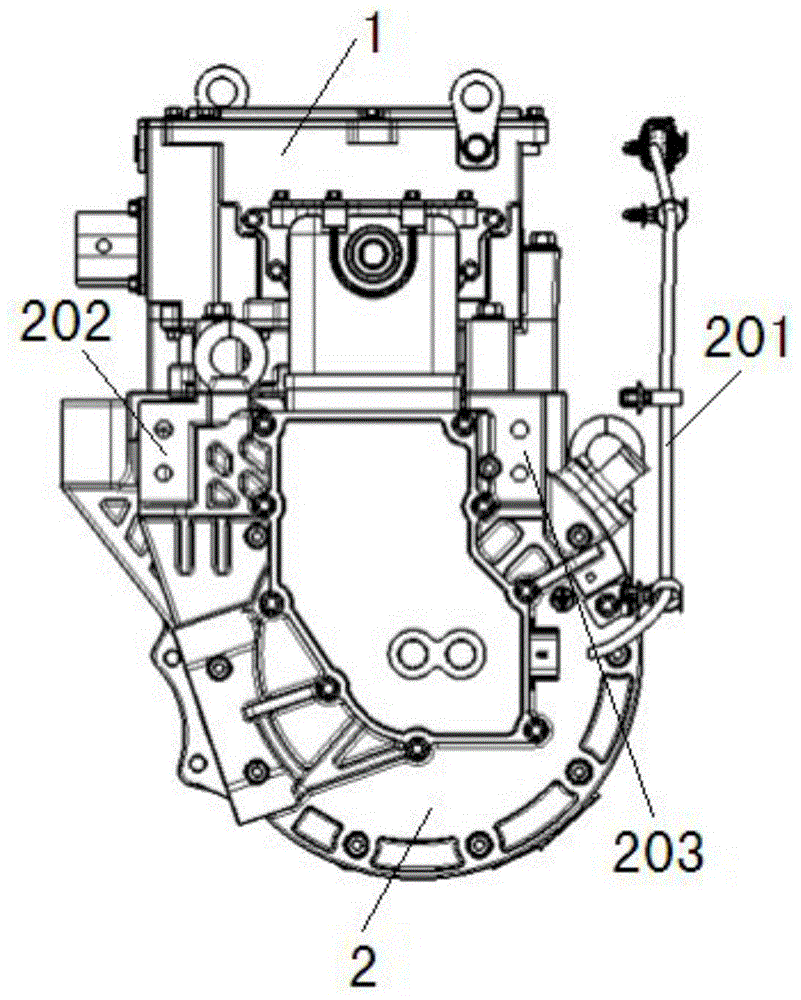

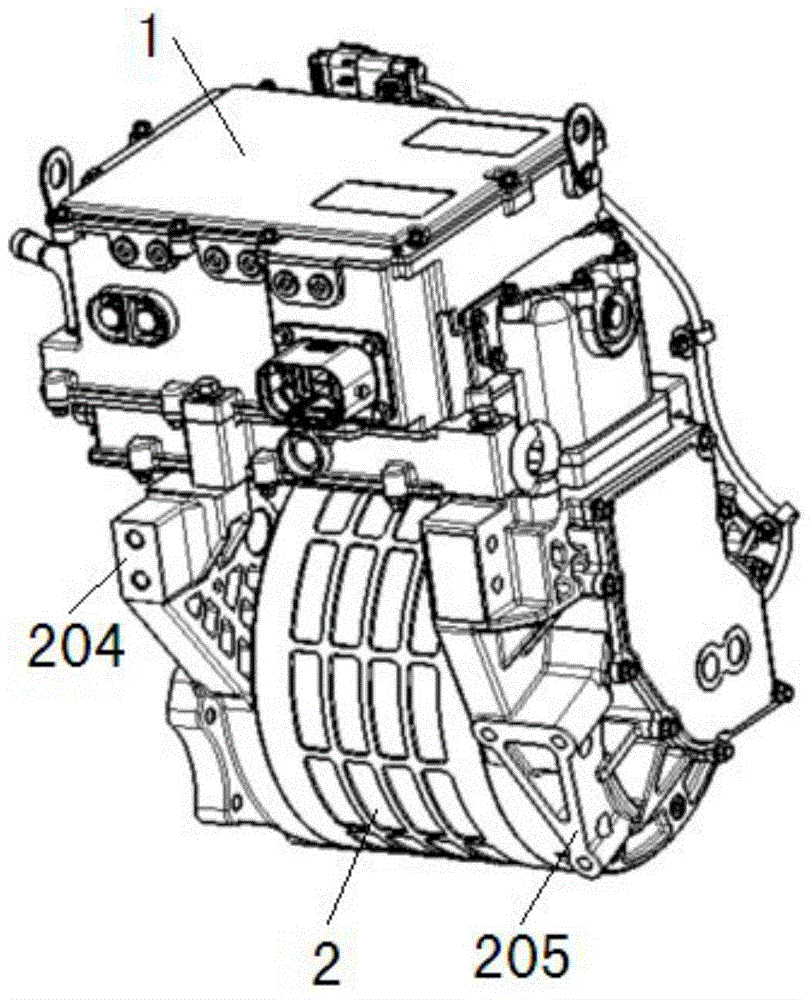

[0023] Such as Figure 1-5 As shown, the drive system includes a motor controller 1 and a motor 2. A plurality of lugs 105 are arranged around the bottom of the motor controller 1, and threaded fixing holes 209 are drilled on the top of the motor 2 corresponding to the lugs 105. The motor control The device 1 is fixed on the top of the motor 2 by bolts passing through the lug 105 and the threaded fixing hole 209 .

[0024] The present invention cancels the suspension installation point on the top of the motor controller 1, and arranges all the suspension installation points on the motor 2. The suspension installation point includes the first suspension installation point 202, the second suspension installation point 203 and the second suspension installation point. Three suspension installation points 204, the positions of these three suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com