Wastewater treatment process

A wastewater treatment and process technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of large quantity and other problems, and achieve the effect of simple process, great popularization and application value, and fast flocculation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Add limestone to the water sample to stir, adjust the pH to 8, and then filter to remove the precipitate;

[0036] (2) Add ozone to the waste water filtered in step (1) for decolorization, add 35 mg of composite flocculant for every 1 L of waste water, stir for 30 min, and let stand for 8 hours to settle and separate;

[0037] (3) filter the waste water of step (2), add active carbon adsorption, and then filter;

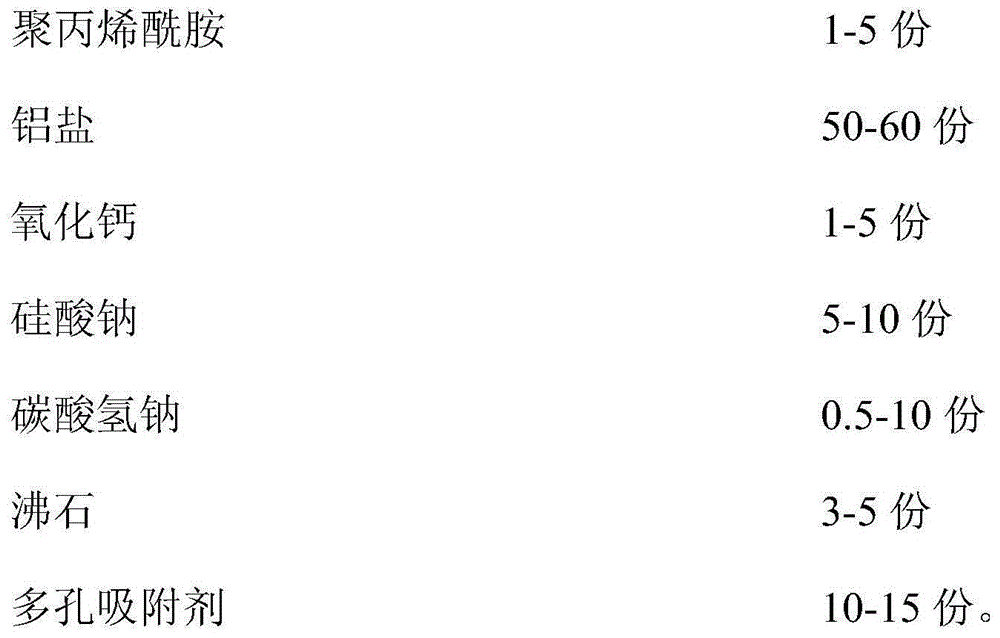

[0038] Wherein the content of each component of the flocculant includes the following raw materials by weight:

[0039]

Embodiment 2

[0041] (1) Add limestone to the water sample to stir, adjust the pH to 6, and then filter to remove the precipitate;

[0042] (2) Add sodium hypochlorite to the waste water filtered in step (1) for decolorization, add 20 mg of composite flocculant for every 1 L of waste water, stir for 20 min, and let stand for 1 hour to settle and separate;

[0043] (3) filter the waste water of step (2), add active carbon adsorption, and then filter;

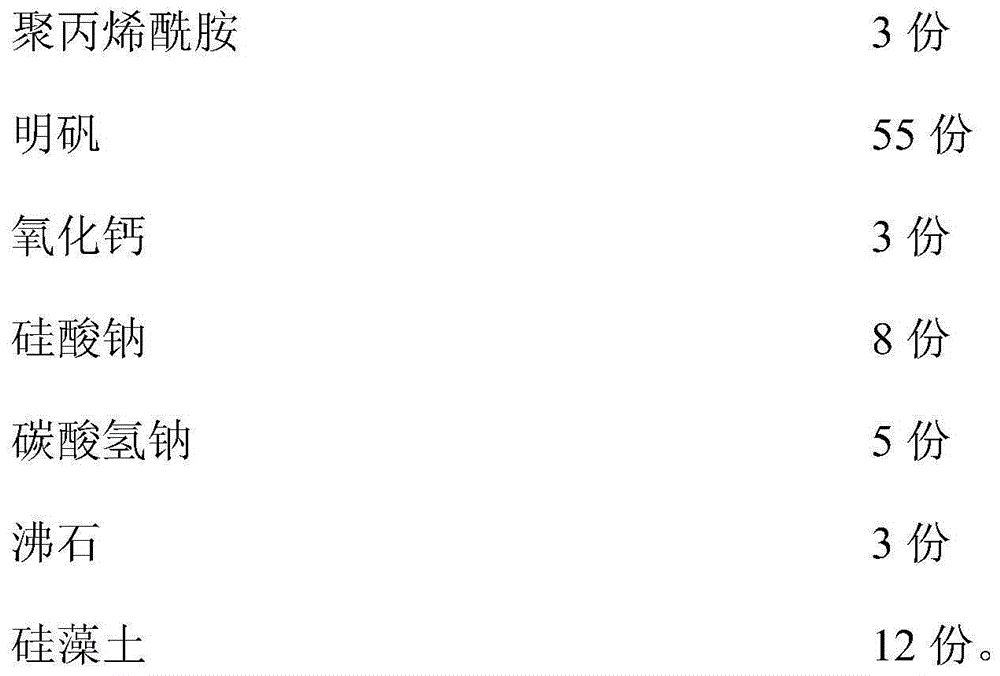

[0044] Wherein the content of each component of the flocculant includes the following raw materials by weight:

[0045]

Embodiment 3

[0047] (1) Add limestone to the water sample to stir, adjust the pH to 6.5, and then filter to remove the precipitate;

[0048] (2) Add hydrogen peroxide to the waste water filtered in step (1) for decolorization, add 50 mg of composite flocculant for every 1 L of waste water, stir for 40 min, and let stand for 10 hours to settle and separate;

[0049] (3) filter the waste water of step (2), add active carbon adsorption, and then filter;

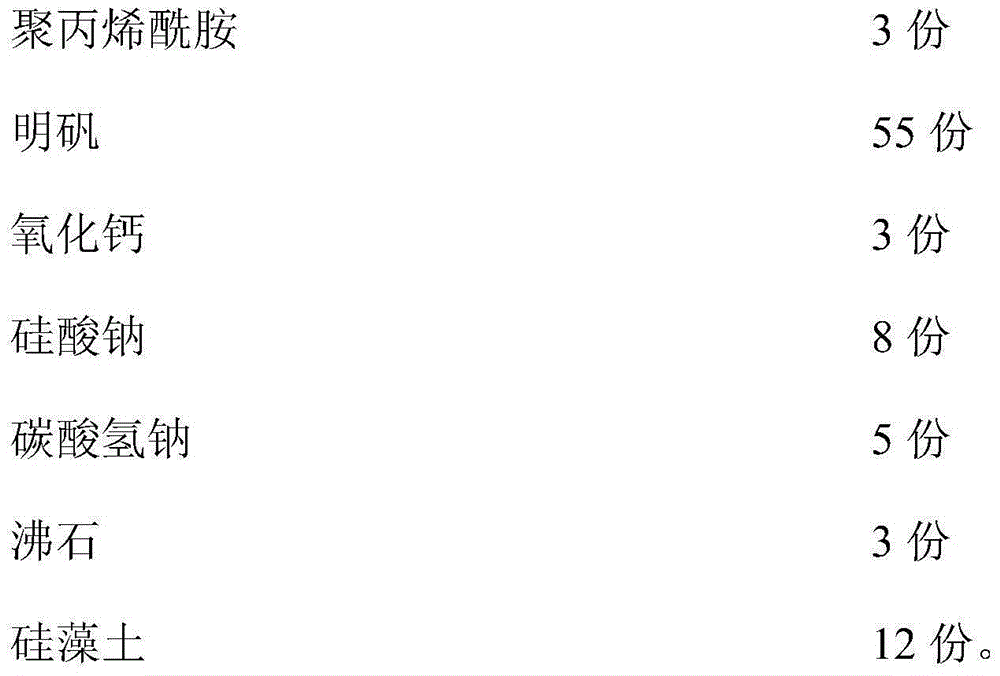

[0050] Wherein the content of each component of the flocculant includes the following raw materials by weight:

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com