An in-situ copolymerization precursor conversion method for preparing mc-sic ultra-high temperature ceramic materials

A technology for the transformation of ultra-high temperature ceramics and precursors, which is applied in the field of in-situ copolymerization precursor transformation for the preparation of MC-SiC ultra-high temperature ceramic materials, can solve the problems of inability to synthesize solubility and high low-temperature cross-linking activity, and achieves easy composition regulation, The effect of simplified process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

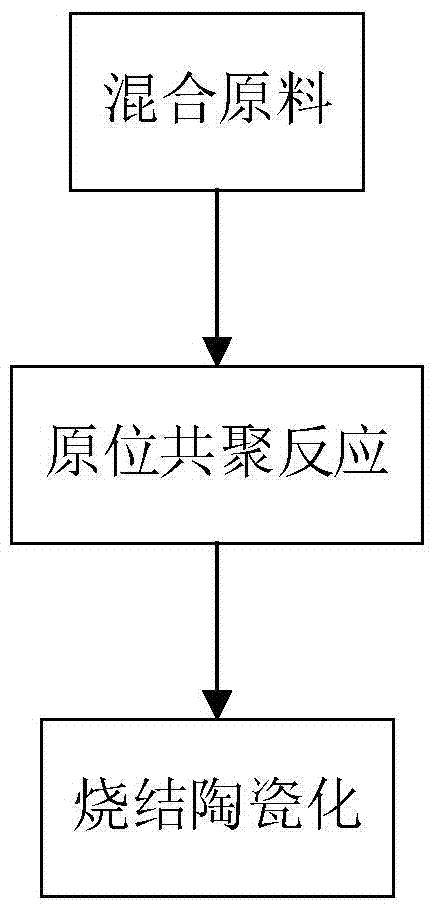

Method used

Image

Examples

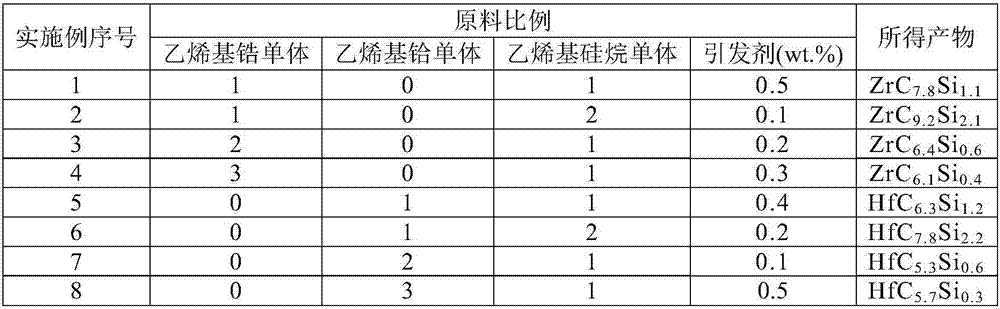

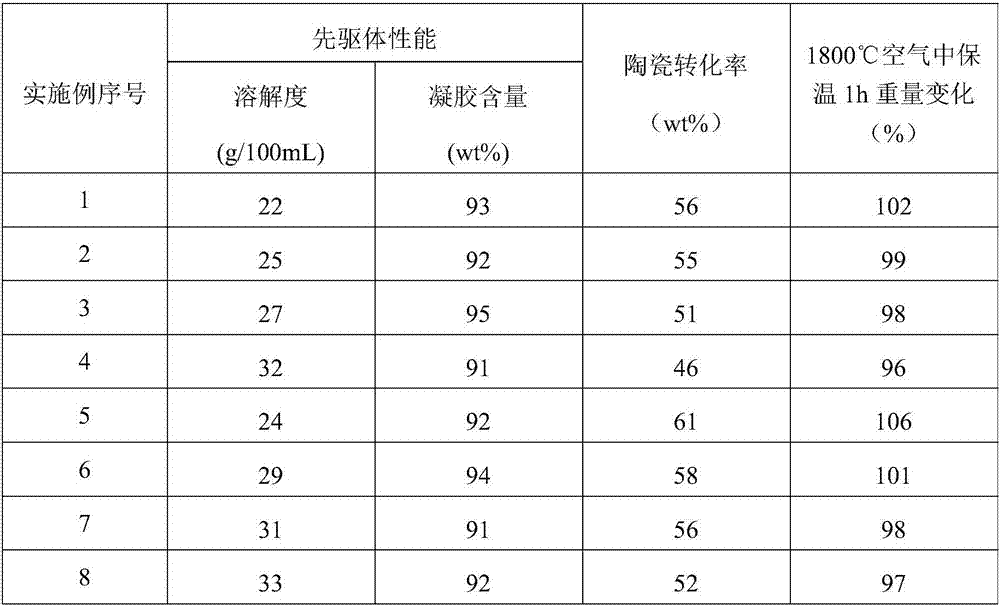

Embodiment 1

[0026] Divinyl zirconocene (molecular formula Cp 2 Zr(C 2 h 4 ) 2 ), trivinylsilane (molecular formula (C 2 h 4 ) 3 SiH) is used as the starting material, after the mold is repeatedly evacuated and filled with dry nitrogen for at least three times, divinylzirconocene, trivinylsilane and dicumyl peroxide DCP are mixed in proportion and injected into the mold; After the mold is filled, the mold is heated to 350°C and kept at this temperature for 10 hours for in-situ copolymerization, then heated to 1000°C and cooled to room temperature to obtain ZrC-SiC ultra-high temperature ceramic material, which is composed of ZrC 7.8 Si 1.1 .

Embodiment 2

[0028] Diallyl zirconocene (molecular formula Cp 2 Zr[(CH 2 )(C 2 h 4 )] 2 ), methyldivinylsilane (molecular formula (C 2 h 4 ) 2 (CH 3 ) SiH) as the starting raw material, vacuumize the mold repeatedly, fill dry nitrogen at least three times, mix diallyl zirconocene, methyl divinyl silane and dicumyl peroxide DCP, inject In the mold; after the mold is filled, the mold is heated to 150°C, and kept at this temperature for 2 hours for in-situ copolymerization, then heated to 1500°C, cooled to room temperature, and the ZrC-SiC ultra-high temperature ceramic material is obtained, the composition is ZrC 6.4 Si 0.6 .

Embodiment 3

[0030] Dibutenyl zirconocene (molecular formula Cp 2 Zr[(CH 2 ) 2 (C 2 h 4 )] 2 ), methyltrivinylsilane (molecular formula (C 2 h 4 ) 3 (CH 3 ) Si) as the starting material, after the mold was repeatedly evacuated and filled with dry nitrogen for at least three times, after mixing dibutenyl zirconocene, methyltrivinylsilane and dibenzoyl peroxide BPO, inject it into the mold ; After the mold is full, heat the mold to 240°C, and keep it warm at this temperature for 6 hours for in-situ copolymerization, then raise the temperature to 1350°C, and cool to room temperature to obtain ZrC-SiC ultra-high temperature ceramic material, which is composed of ZrC 9.2 Si 2.1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com