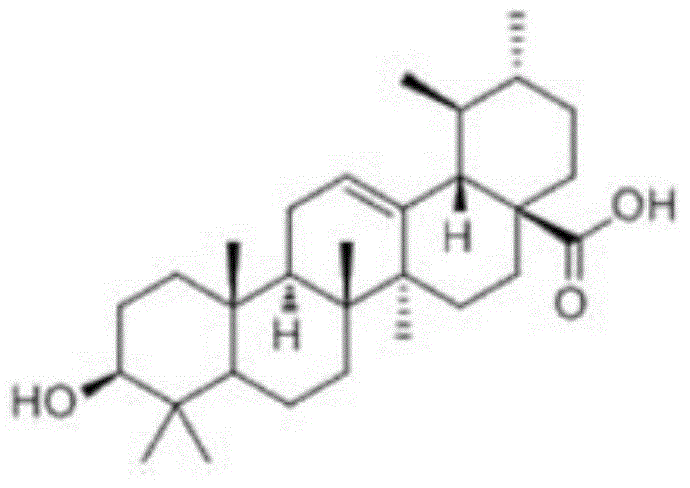

Method for extracting ursolic acid and oleanolic acid from blueberry fruits

A technology of oleanolic acid and ursolic acid, applied in the direction of steroids, organic chemistry, etc., can solve the problems of few reports on the extraction and refining process of ursolic acid and oleanolic acid, and achieve low cost and simple extraction process , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Select high-quality blueberry fruit as a raw material, rinse it with clean water, control the outer moisture after rinsing, and then dry the blueberry fruit with the outer moisture controlled at 55°C for 1.0h. The dried blueberry fruit is crushed into particles with a diameter of 80 mesh. Mix the crushed blueberry fruit with ethanol solution, the ethanol solution is used as the extractant, the mass percentage concentration is 90%, the solid-liquid ratio of the crushed blueberry fruit and the ethanol solution is adjusted to be 1:20, and the extraction is carried out under ultrasonic conditions for 45min. to 50W to obtain an extract. The extract is subjected to centrifugation for solid-liquid separation at a rotational speed of 4000 rpm, the residue is removed by filtration, the supernatant is collected, and the supernatant is adsorbed on a macroporous adsorption resin column. The polystyrene type macroporous resin is filled in the macroporous adsorption resin column, an...

Embodiment 2

[0028] Select high-quality blueberry fruit as a raw material, rinse it with clean water, control the outer moisture after rinsing, and then dry the blueberry fruit with the outer moisture controlled at 50°C for 1.0h. The dried blueberry fruit is crushed into particles with a diameter of 80 mesh. Mix the crushed blueberry fruit with ethanol solution, the ethanol solution is used as the extractant, the mass percentage concentration is 100%, the solid-liquid ratio of the crushed blueberry fruit and the ethanol solution is adjusted to be 1:15, and the extraction is carried out under ultrasonic conditions for 60min. to 150W to obtain an extract. The extract was subjected to centrifugation for solid-liquid separation at a centrifugation speed of 8000 rpm, the residue was removed by filtration, the supernatant was collected, and the supernatant was adsorbed on a macroporous adsorption resin column. The polystyrene type macroporous resin is filled in the macroporous adsorption resin ...

Embodiment 3

[0030] Select high-quality blueberry fruit as a raw material, rinse it with clean water, control the outer moisture after rinsing, and then dry the blueberry fruit with the outer moisture controlled at 60°C for 1.0h. The dried blueberry fruit is crushed into particles with a diameter of 80 mesh. Mix the crushed blueberry fruit with ethanol solution, the ethanol solution is used as the extractant, the mass percentage concentration is 80%, the solid-liquid ratio between the crushed blueberry fruit and the ethanol solution is adjusted to be 1:25, and the extraction is carried out under ultrasonic conditions for 30min. to 100W to obtain an extract. The extract was subjected to centrifugation for solid-liquid separation at a rotational speed of 3000 rpm, the residue was removed by filtration, the supernatant was collected, and the supernatant was adsorbed on a macroporous adsorption resin column. The polystyrene type macroporous resin is filled in the macroporous adsorption resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com