A cleaning rubber softener

A rubber softener and softener technology, which is applied in the field of new clean softeners, can solve the problems that there are no clean rubber softeners available, and achieve the effects of ensuring long-term industrial production, low cost, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-6

[0050] The softening agents of Example 1-3 and Comparative Example 1-6 were prepared respectively by adopting the above-mentioned segmented blending method, and the formula and quality test results of Example 1-3 and Comparative Example 1-6 are shown in Table 2 below. Analysis method Same as Table 1.

[0051] Table 2: The material proportion (wt%) of embodiment 1-3 and comparative example 1-6

[0052]

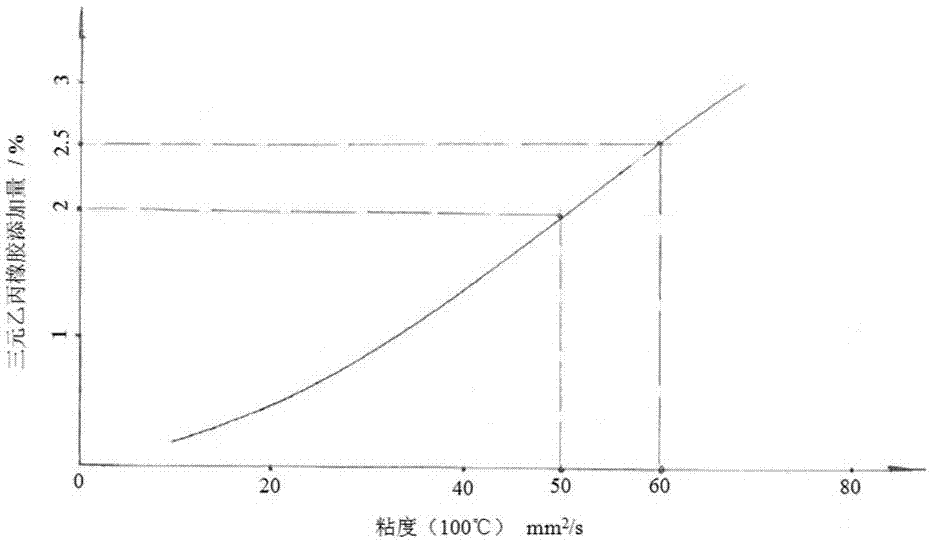

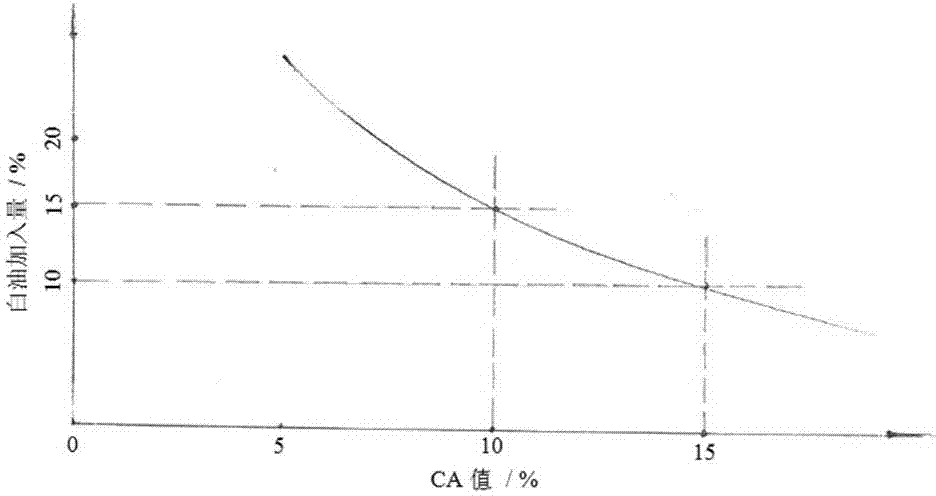

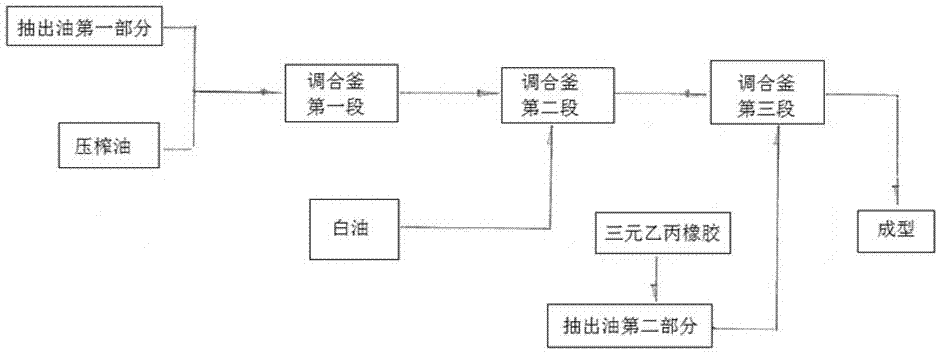

[0053] As can be seen from Table 2, embodiment 1-3 can meet quality index requirement. It can be seen that 60-65% of the extracted oil (the aromatic content is not higher than 20%), 20-25% of the pressed residue, 10-15% of the white oil and 2-2.5% of the EPDM rubber, using the above The rubber softener is prepared by stepwise blending method, and its density, viscosity, flash point, water content, volatile matter and CA value can all meet the quality index requirements in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com