High temperature resistance sagging prevention sprayable non-solidification rubber asphalt waterproof coating and preparation method thereof

An asphalt waterproof coating, non-curing rubber technology, used in building thermal insulation materials, building components, buildings and other directions, can solve the problems of poor low temperature flexibility, high spray construction temperature, easy sliding, flowing, etc., to achieve adhesion and durability. Good adhesion, saving energy and material loss, simple and easy-to-control production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0025] Embodiment 1~7 all adopts following method to prepare:

[0026] 1. Pump the asphalt and rubber oil in the molten state into the reaction kettle through the insulation pipe, stir for 10 minutes after heating up to the temperature of the material at 120°C;

[0027] 2. Put in the weighed styrene-butadiene rubber, random polypropylene and tackifying resin, stir and heat up to 180°C, then stir at constant temperature for 2 hours;

[0028] 3. Put in the weighed fly ash and rheological additives, stir at a constant temperature of 180°C for 1 hour to form a uniform liquid, cool the circulating water to 150°C and filter out the material to obtain the finished product.

Embodiment 1

[0030] In this embodiment, the non-curable rubber asphalt waterproof coating that can be sprayed with high temperature resistance and anti-sagging is composed of the following mass percentages: 90# asphalt 15%, aromatic rubber oil 22%, naphthenic rubber oil 5%, star styrene-butadiene Styrene-styrene copolymer (SBS) 1%, styrene-butadiene copolymer (SBR) 7%, random polypropylene 7%, C9 petroleum resin 8%, C5 petroleum resin 7%, fly ash 25%, fumed silica 1%, organic montmorillonite 2%.

[0031] The star-shaped styrene-butadiene-styrene copolymer (SBS) described in the present embodiment is the SBS411 of Korea LG Company; The fumed silica is the M-5 of Cabot; The styrene-butadiene The parameters of vinyl copolymer (SBR) are as follows:

[0032] project

[0033] Its parameter of described random polypropylene (APP) is as follows:

[0034] project

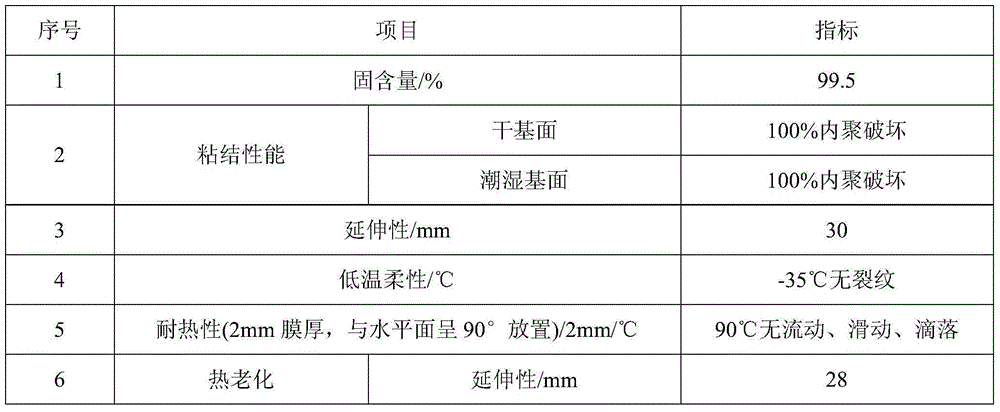

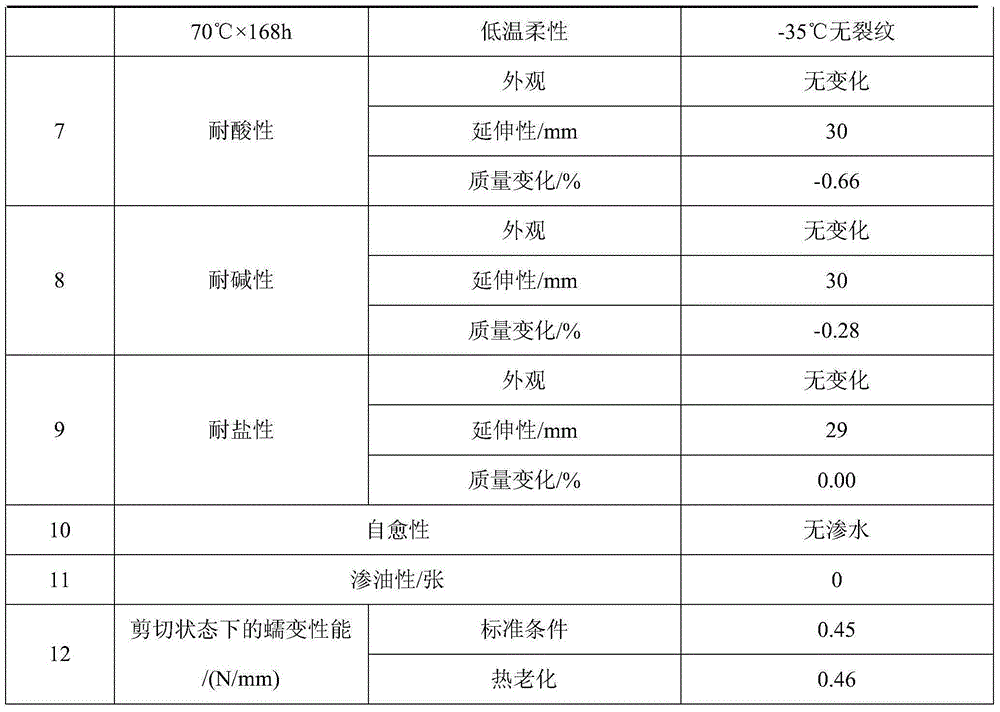

[0035] The performance of the non-curing rubber asphalt waterproof coating described in this embodiment is as f...

Embodiment 2

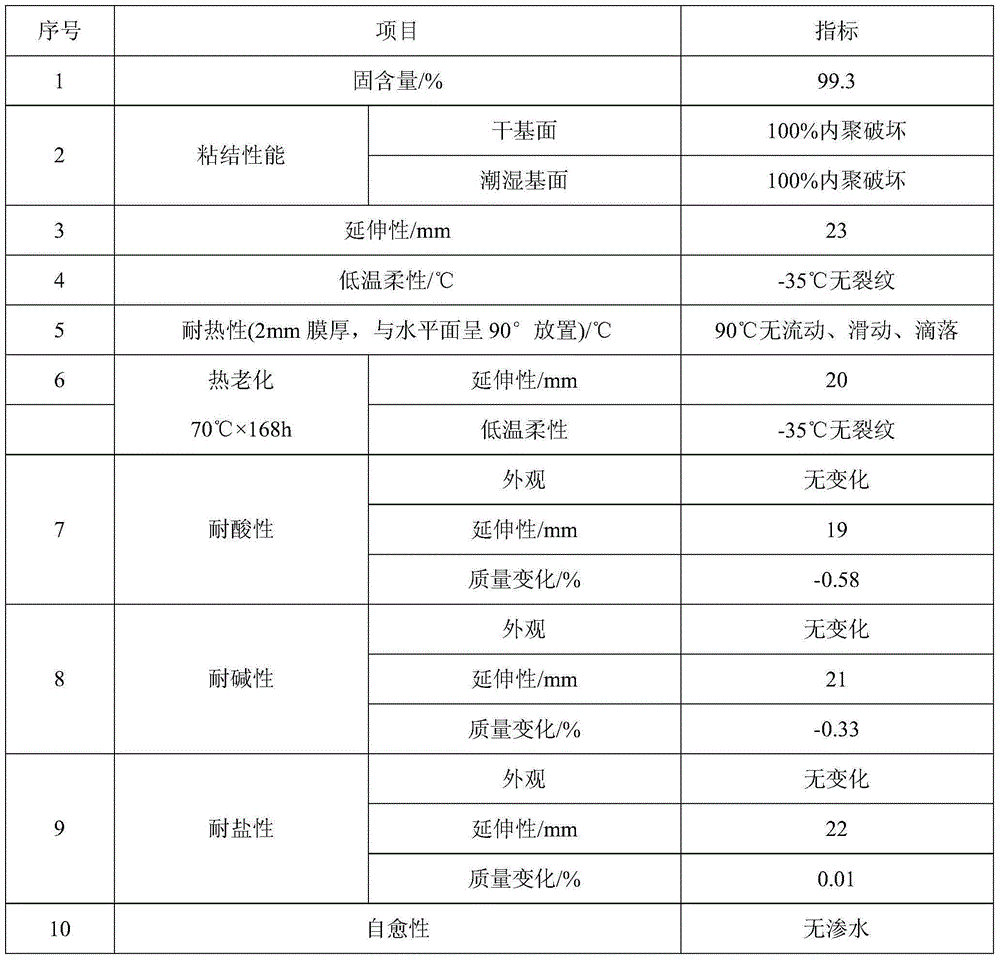

[0043] In this embodiment, the high-temperature-resistant and anti-sag sprayable non-curing rubber asphalt waterproof coating is composed of the following mass percentages: 13% of 90# asphalt, 21% of 110# asphalt, 20% of aromatic rubber oil, star-shaped styrene-butadiene - Styrene Copolymer (SBS) 3%, Styrene-Butadiene Copolymer (SBR) 3%, Random Polypropylene 7%, C9 Petroleum Resin 4%, C5 Petroleum Resin 3%, Fly Ash 15 %, organic montmorillonite 2%, polyamide modified polyacrylate 8%, polyamide wax 1%.

[0044] The star-shaped styrene-butadiene-styrene copolymer (SBS) described in the present embodiment is the SBS411 of Korea LG Company; Its parameter of described styrene-butadiene copolymer (SBR) is as follows:

[0045] project

indicators

Granularity (mesh)

≤40

molecular weight

200,000 to 300,000

bound styrene

21.5~35

[0046] Raw Rubber Mooney Viscosity

48~86

[0047] Its parameter of described random...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com