High corrosion resistant material for protecting pipeline and preparation method thereof

A high corrosion resistance, pipeline technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as high cost and inconvenient maintenance, and achieve excellent physical and mechanical properties, good corrosion resistance, and broad The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

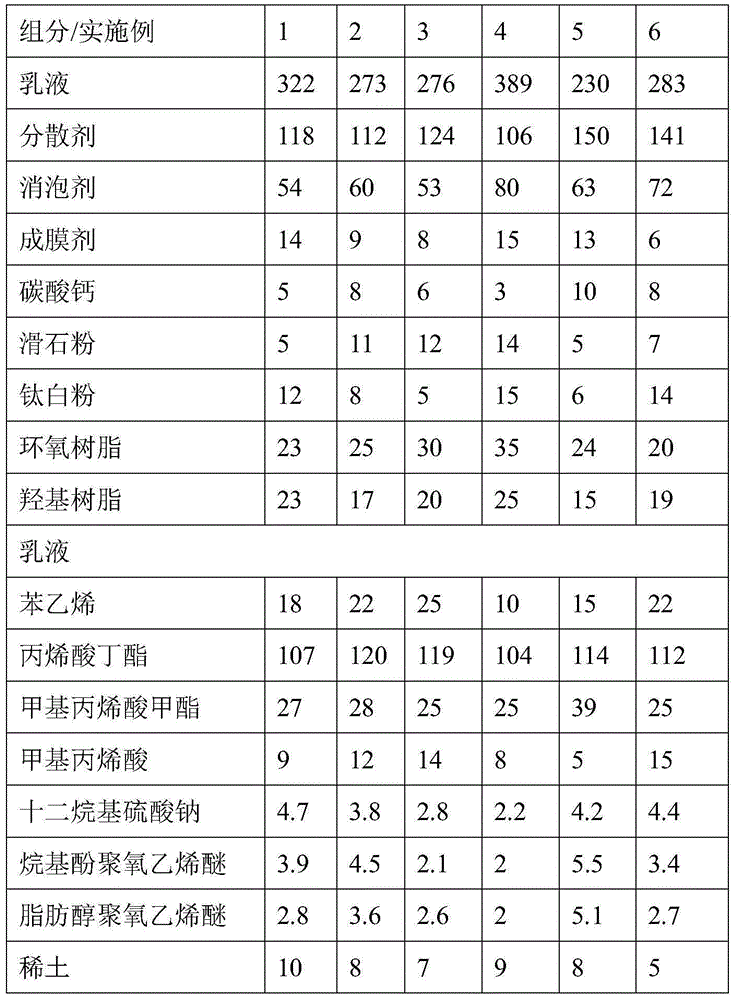

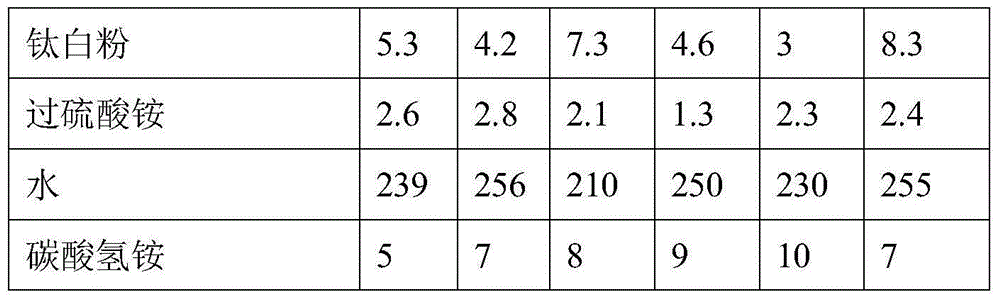

Embodiment 1

[0019] The method for preparing the above-mentioned highly corrosion-resistant material for protecting pipelines comprises the following steps:

[0020] Step 1. Preparation of emulsion: Weigh a certain amount of water according to the proportion, add sodium lauryl sulfate, alkylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, titanium dioxide and ammonium persulfate, and stir for 5 minutes. Add styrene and butyl acrylate while stirring, continue stirring for 10 minutes, add methyl methacrylate, methacrylic acid and rare earth, stir for 3 minutes, add ammonium bicarbonate, and stir evenly;

[0021] Step 2. Preparation of highly corrosion-resistant materials: Add various components to the emulsion, stir evenly, adjust pH, and test for later use.

Embodiment 2

[0023] The method for preparing the above-mentioned highly corrosion-resistant material for protecting pipelines comprises the following steps:

[0024] Step 1. Preparation of emulsion: Weigh a certain amount of water according to the proportion, add sodium lauryl sulfate, alkylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, titanium dioxide and ammonium persulfate, and stir for 8 minutes. Add styrene and butyl acrylate while stirring, continue stirring for 15 minutes, add methyl methacrylate, methacrylic acid and rare earth, stir for 3 minutes, add ammonium bicarbonate, and stir evenly;

[0025] Step 2. Preparation of highly corrosion-resistant materials: Add various components to the emulsion, stir evenly, adjust pH, and test for later use.

Embodiment 3

[0027] The method for preparing the above-mentioned highly corrosion-resistant material for protecting pipelines comprises the following steps:

[0028] Step 1. Preparation of emulsion: Weigh a certain amount of water according to the proportion, add sodium lauryl sulfate, alkylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, titanium dioxide and ammonium persulfate, and stir for 3 minutes. Add styrene and butyl acrylate while stirring, continue stirring for 10 minutes, add methyl methacrylate, methacrylic acid and rare earth, stir for 5 minutes, add ammonium bicarbonate, and stir evenly;

[0029] Step 2. Preparation of highly corrosion-resistant materials: Add various components to the emulsion, stir evenly, adjust pH, and test for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com