Crease resistance finishing agent, fabric crease resistance finishing method, and crease-resistant fabric

An anti-wrinkle finishing agent and anti-wrinkle finishing technology, which is applied in the field of anti-wrinkle fabrics and anti-wrinkle finishing agents, can solve the problems of high curing temperature of anti-wrinkle finishing agents, high free formaldehyde content in fabrics, and long curing time, so as to shorten the curing time and lower the curing temperature , the effect of reducing the content of free formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The material proportions in the present invention are all described in mass fractions, and the sum of the mass fractions of all material components of the anti-wrinkle finishing agent is 100%.

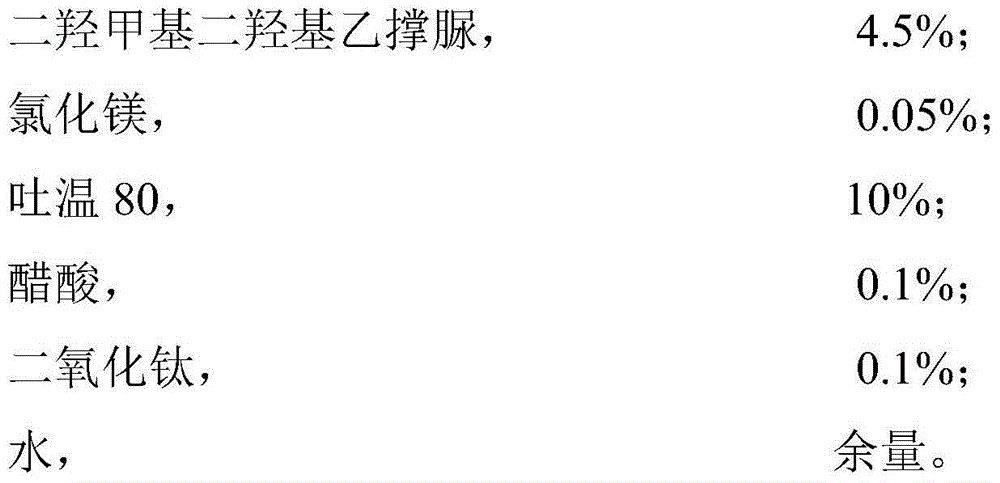

[0019] The anti-wrinkle finishing agent provided by the invention includes cellulose crosslinking agent, dispersant, acetic acid, titanium dioxide and water. The mass fraction of each raw material is as follows:

[0020]

[0021] Preferably, the cellulose crosslinking agent can be any cellulose crosslinking agent well known and applicable to those skilled in the art, such as dimethylol dihydroxyethylene urea (DMDHEU), melamine formaldehyde resin or dimethylolethylene Urea (DMEU). As the dispersant, any dispersant that is well known and applicable to those skilled in the art can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com