Two regenerative cooling afterburners with sound cavities and application thereof

An afterburner, cooling technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of short working time, not too long life, not many applications, etc., to suppress high frequency unstable combustion and vibration reduction, increase working time and life, improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

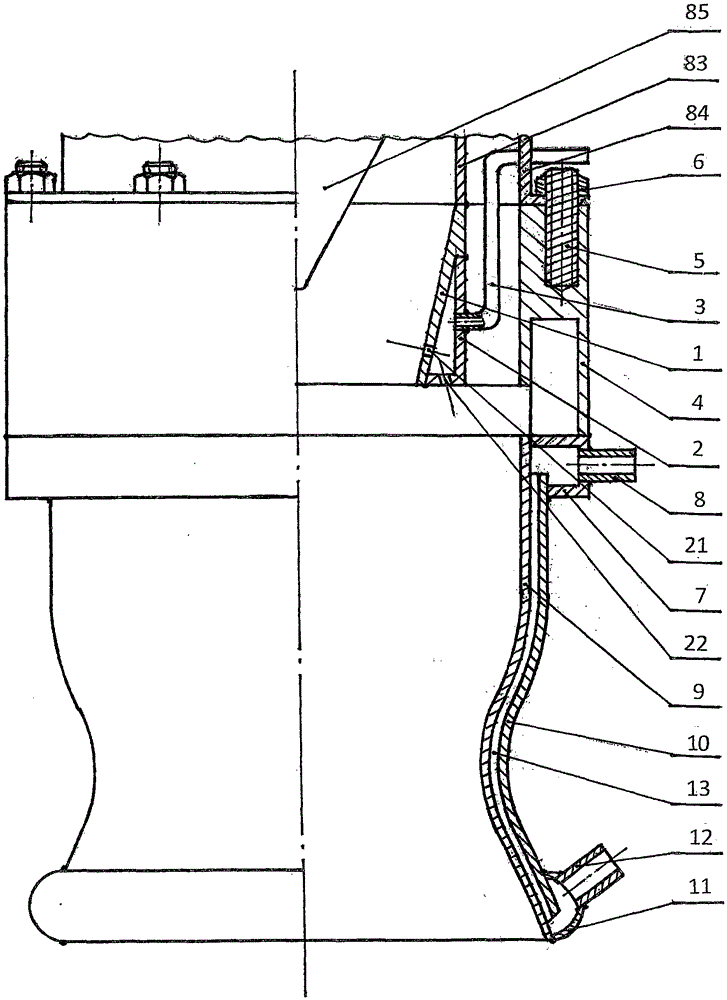

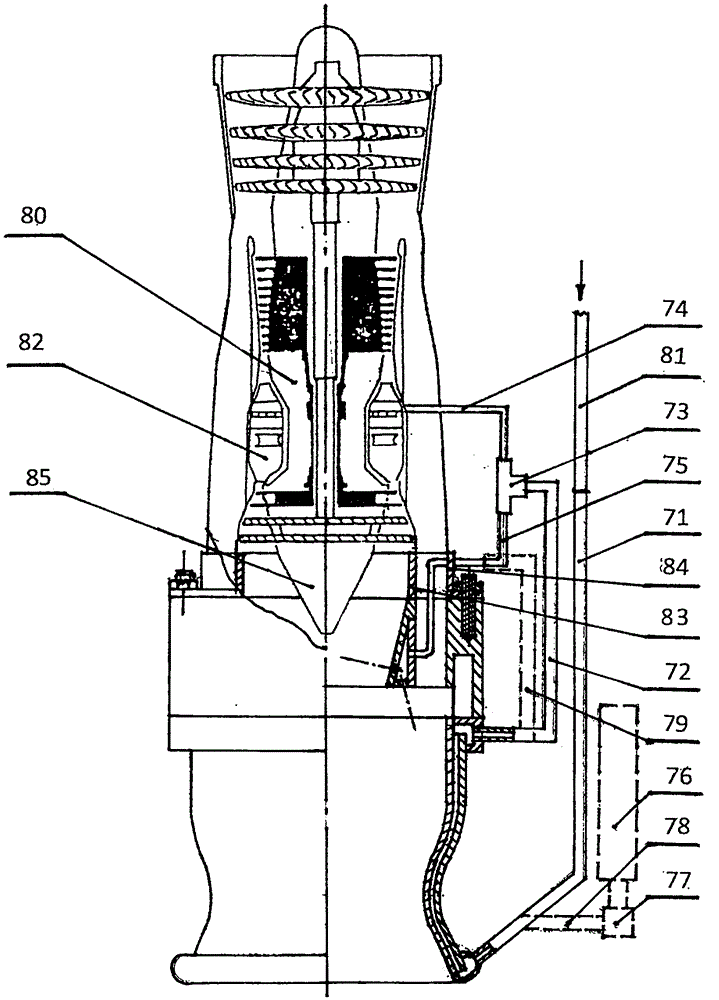

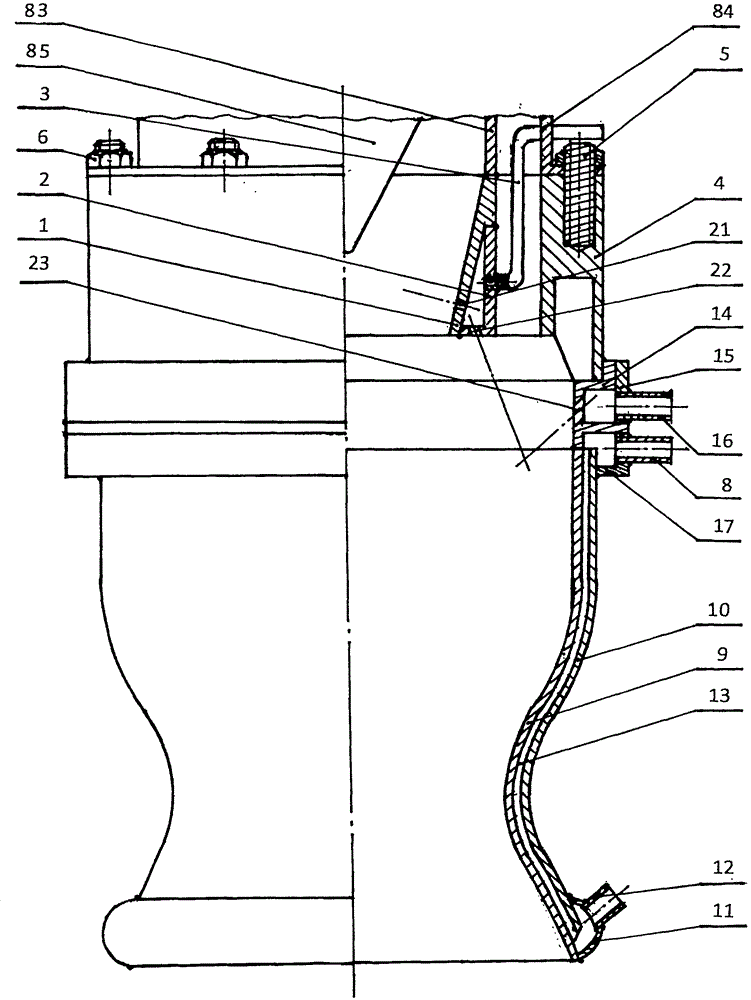

[0028] figure 1 , figure 2 , image 3 , Figure 4 ,Include Figure 5-1 , Figure 5-2 and Figure 5-3 of Figure 5 and Figure 6 It is the preferred embodiment of two types of regenerative cooling afterburner chambers with acoustic cavity in the present invention.

[0029] Such as figure 1 and figure 2 As shown, the first regenerative cooling afterburner with acoustic cavity in the present invention is composed of a middle part, an outer ring part and a kerosene pipeline or a liquid hydrogen system. Tube 3, the outer ring part includes straight groove acoustic cavity 4, screw pile 5, nut 6, coolant outflow collector 7, coolant outlet pipe 8, afterburner inner wall 9, afterburner outer wall 10, coolant inflow Collector 11 and coolant inlet pipe 12, kerosene pipeline including kerosene supply pipe 71 for cooling, kerosene output pipe 72 for cooling, kerosene tee linking with the kerosene main pipe 81 and combustion chamber 82 of aviation gas turbine engine 80. Pipe 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com