Ag/Ag2O-modified SnO2 porous composite and application of Ag/Ag2O-modified SnO2 porous composite to hydrogen detection

A porous composite material, hydrogen technology, applied in the field of gas sensing, can solve the problems of complex preparation process, high working temperature and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) SnO 2 Preparation of the precursor: 0.35g of SnCl 4 ·5H 2 O was dissolved in 8 mL of glycerol and 30 mL of isopropanol solvent, transferred to a reaction kettle, reacted at 180 °C for 12 h, cooled naturally to room temperature, and centrifuged to obtain SnO 2 Precursor.

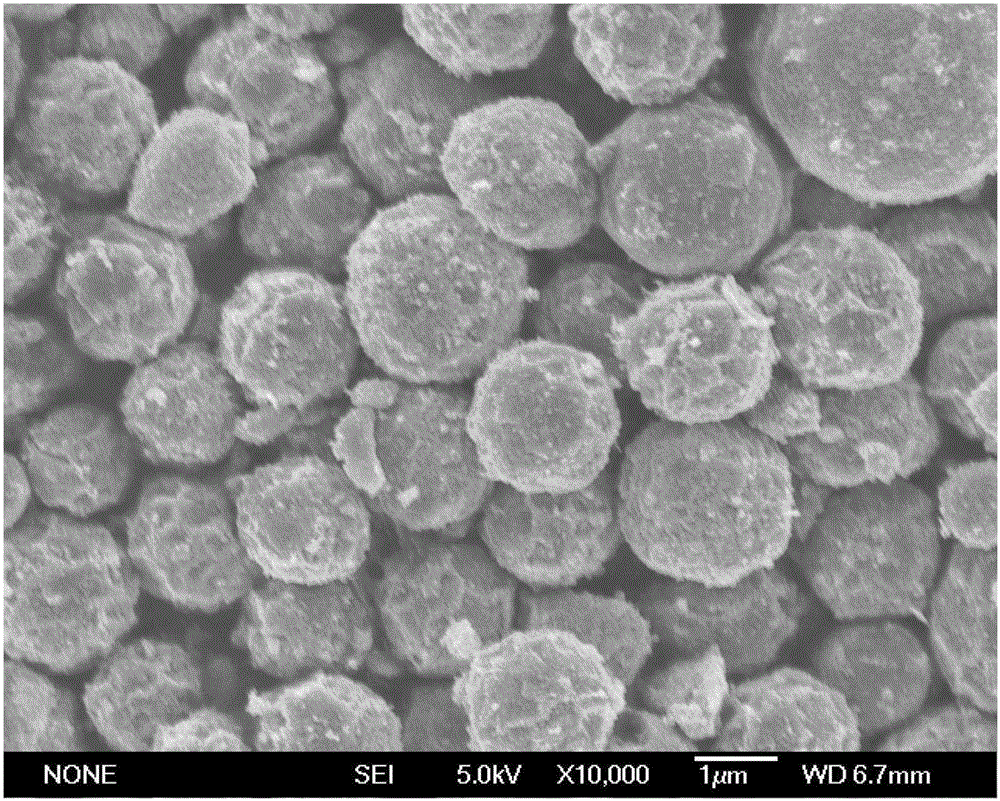

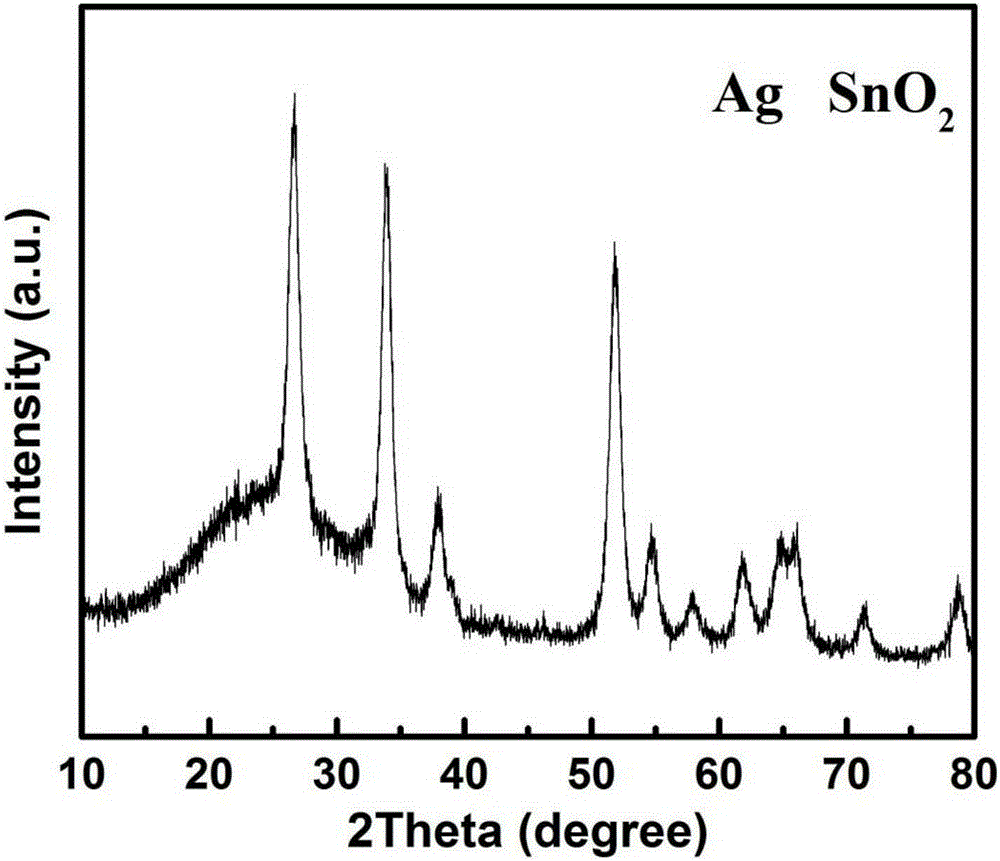

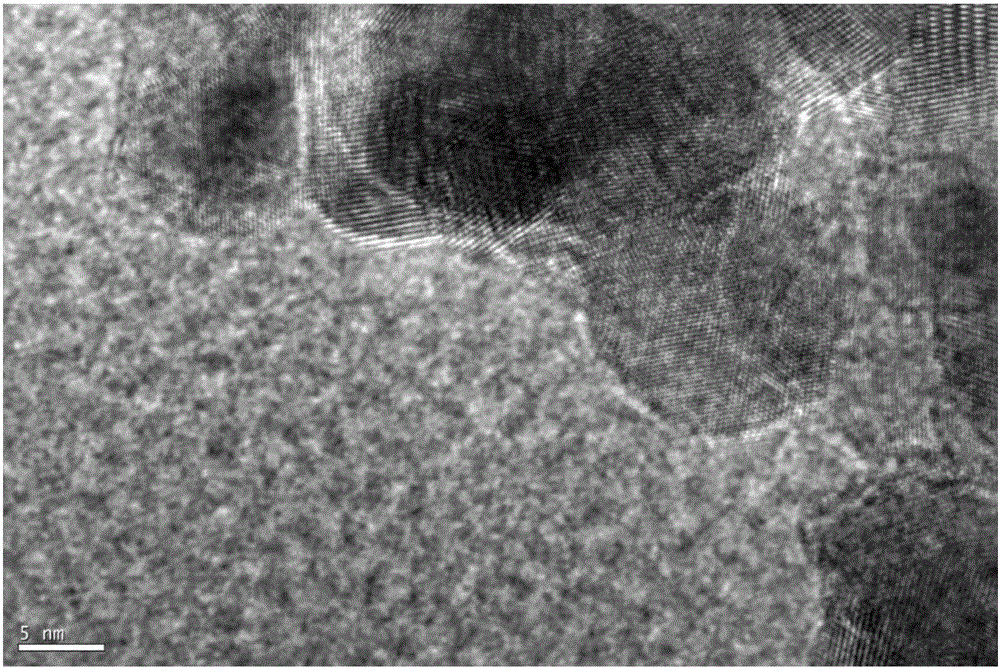

[0017] 2) Ag / Ag 2 O modified porous SnO 2 Preparation of composite materials: 100mg of SnO 2 precursor and 5 mg of AgNO 3 Stir in 2 mL of ethanol for 15 minutes, dry at 80°C for 1 hour, and calcine at 300°C in air for 2 hours to obtain Ag / Ag 2 O-modified SnO 2 Porous microsphere materials (such as figure 1 ). The structure and composition of the above samples were studied, figure 2 is Ag / Ag 2 O-modified SnO 2 The XRD spectrum of the porous microsphere material, the peak position of the diffraction peak is consistent with PDF#41-1445 (source: International Center for Diffraction ICDD), because the content of silver in the product is less, and Ag and Ag 2 The main diffraction peaks of O ...

Embodiment 2

[0021] Same as Example 1, but AgNO 3 The dosage was changed to 2mg. The response value of the composite material to 200ppm hydrogen is 10, the response time is 3s, and the recovery time is 30s. It has no response to the concentration of 200ppm carbon monoxide and methane. The detection limit of hydrogen is 1000ppb.

Embodiment 3

[0023] Same as Example 1, but AgNO 3 The dosage was changed to 8mg. The response value of the composite material to 200ppm hydrogen is 22, the response time is 4s, and the recovery time is 35s. It has no response to the concentration of 200ppm carbon monoxide and methane. The detection limit of hydrogen is 500ppb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com