Preparation method for Ag/carya cathayensis peel based active carbon composite capacitor electrode material

A technology of capacitor electrodes and composite materials, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors to achieve good electrical conductivity and maintain electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: a kind of preparation method of Ag / hickory cattail shell base activated carbon composite capacitive electrode material is specifically finished according to the following steps:

[0015] Step 1: 1) Place the outer cattail shell of the hickory nut outdoors to dry naturally, air-dry, and pulverize in a pulverizer, and the powder passes through 200 mesh. 2) Carbonizing the hickory cattail shell powder in step 1) under the protection of nitrogen, the carbonization temperature is 500° C., and the carbonization time is 0.5 hour. 3) Mix the carbonized material in step 2) with KOH evenly and then activate it under the protection of nitrogen. The weight ratio of carbonized material to KOH is 1:1, the activation temperature is 800°C, and the activation time is 0.5 hours.

[0016] 4) After the product obtained in step 3) is cooled, wash it with dilute hydrochloric acid and acetic acid respectively, and then wash it with distilled water until the pH value ...

specific Embodiment approach 2

[0018] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is:

[0019] In the step, the particle size is over 400 mesh, the carbonization temperature is 650°C, the carbonization time is 1.0 hour, the weight ratio of carbonization material to sodium carbonate is 1:6, the activation temperature is 900°C, the activation time is 1.5 hours, and the heating rate is 10°C / min, the concentration of dilute hydrochloric acid is 0.2mol / L, the concentration of acetic acid is 1.0mol / L, and the quality of the hickory cattail shell base activated carbon powder that adds is 1.0g. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the particle size in the step is over 600 mesh, the carbonization temperature is 800°C, the carbonization time is 2.0 hours, the weight ratio of carbonization material to sodium carbonate is 1:10, the activation temperature is 1000°C, and the activation time is 2 hours, The heating rate is 10°C / min, the concentration of dilute hydrochloric acid is 0.3 mol / L, the concentration of acetic acid is 2.0 mol / L, and the mass of hickory cattail shell-based activated carbon powder added is 1.0 g. Others are the same as the first embodiment.

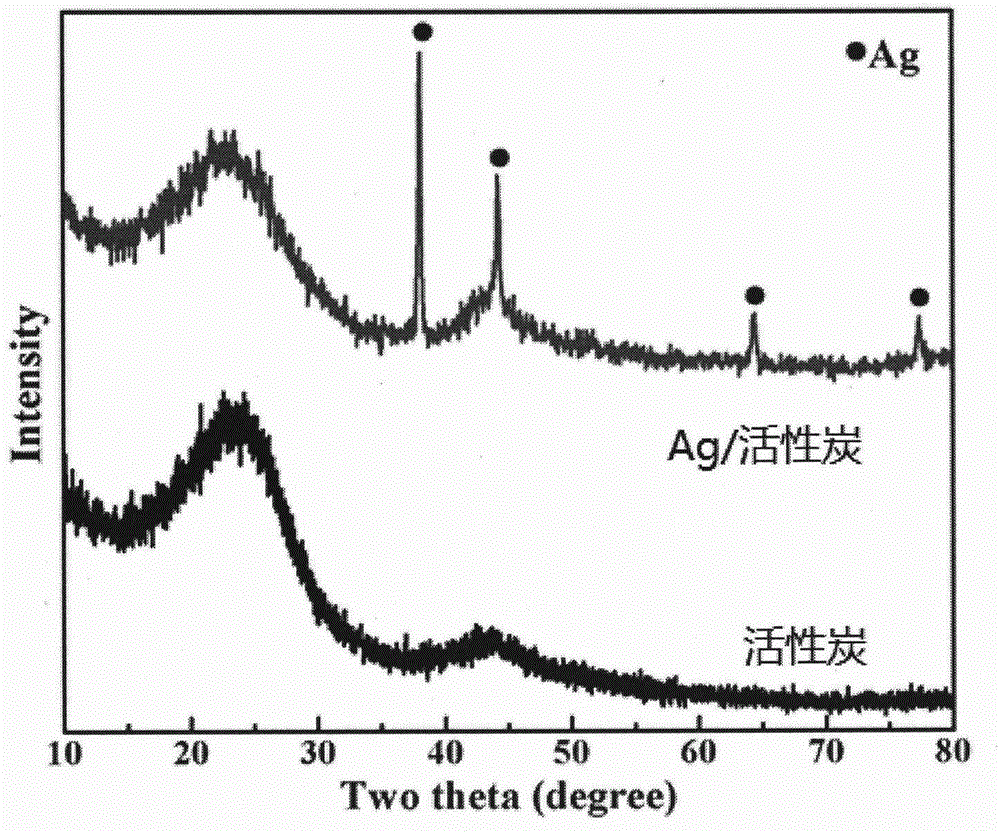

[0021] figure 1 It is the XRD figure of the Ag / hickory cattail shell base activated carbon composite capacitor electrode material prepared by the specific embodiment two, from the figure, it can be observed that the standard diffraction peak of Ag and the amorphous carbon diffraction peak representing bamboo charcoal indicate the successful synthesis of Ag / bamboo charcoal composite material.

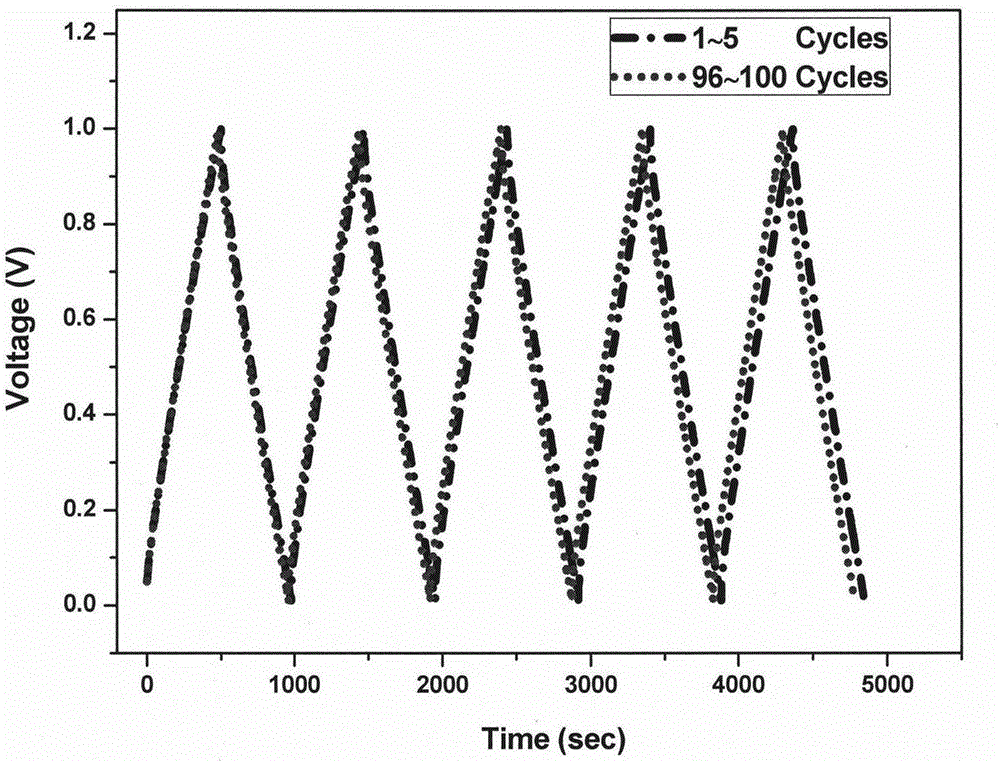

[0022] figure 2 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com