Silicon carbide schottky diode and preparation method thereof

A technology of Schottky diodes and diodes, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult to reduce forward voltage drop, difficult to reduce overall power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

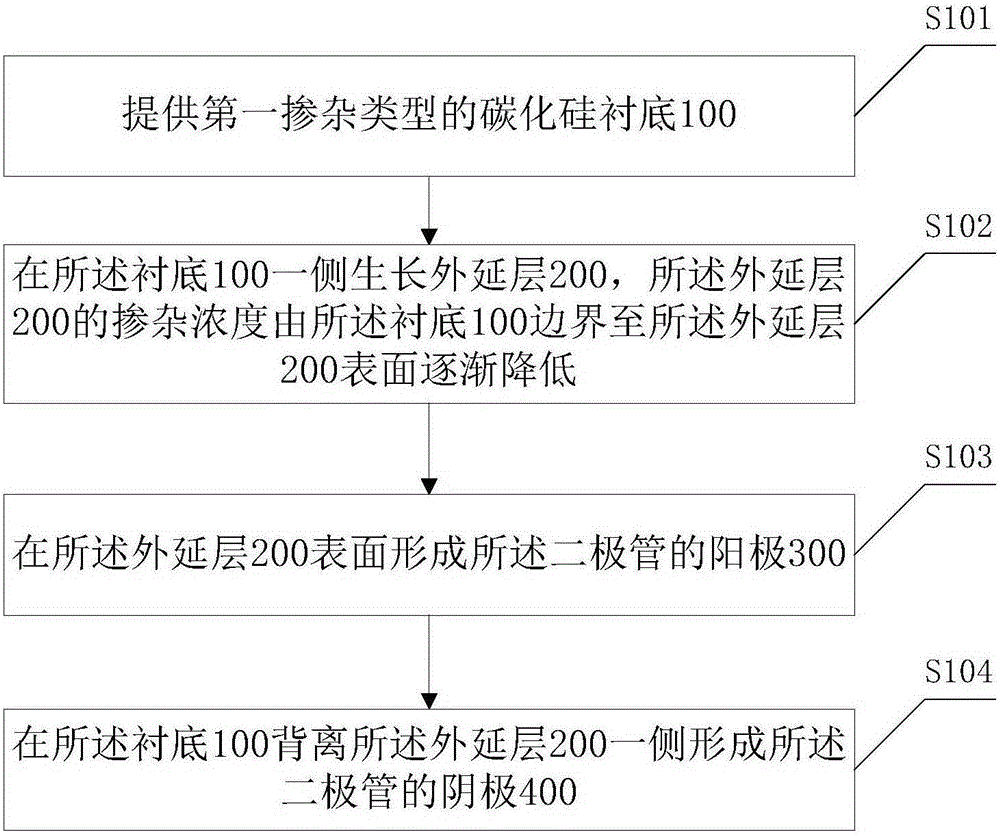

[0048] Correspondingly, the embodiment of the present invention also provides a method for manufacturing a silicon carbide Schottky diode, including:

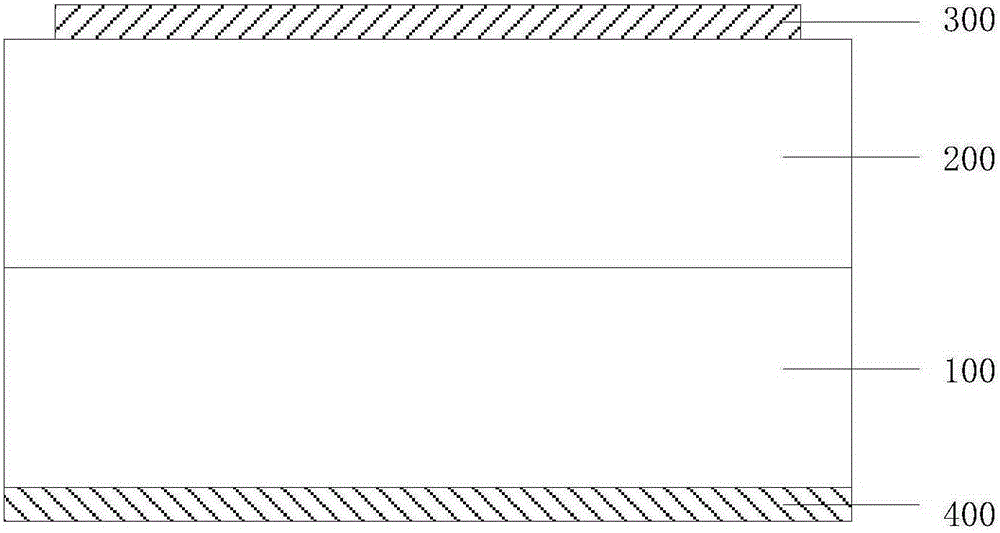

[0049] providing a silicon carbide substrate of a first doping type;

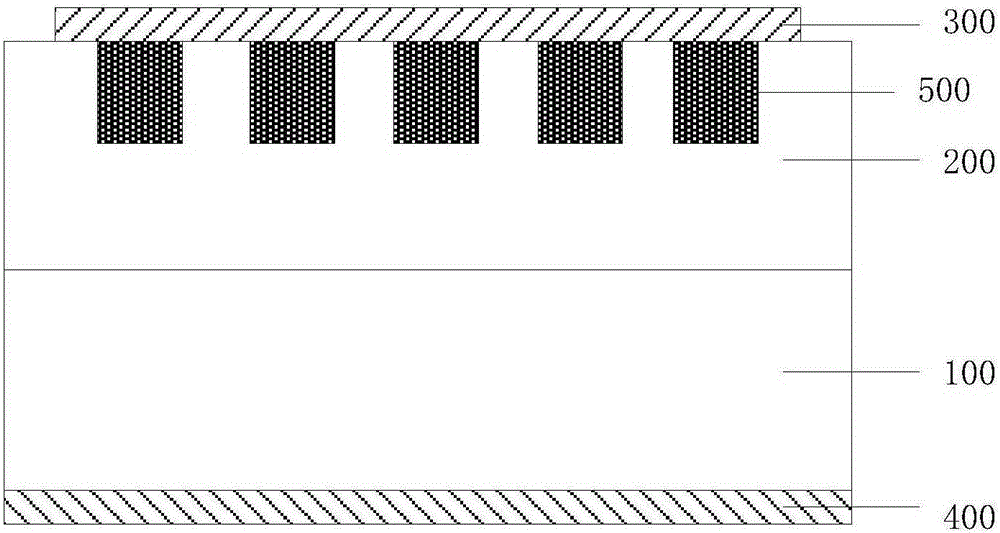

[0050] growing an epitaxial layer on one side of the substrate, the doping concentration of the epitaxial layer gradually decreases from the boundary of the substrate to the surface of the epitaxial layer;

[0051] forming an anode of the diode on the surface of the epitaxial layer;

[0052] The cathode of the diode is formed on the side of the substrate away from the epitaxial layer.

[0053] An embodiment of the present invention provides a silicon carbide Schottky diode and a manufacturing method thereof, wherein the doping concentration of the epitaxial layer of the diode gradually increases from the boundary of the anode to the boundary of the substrate. For the epitaxial layer of the diode, a high doping concentration is beneficial to reduce the on-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com