A resistive variable memory and a method for increasing its positive and negative current difference

A resistive variable memory and resistive variable technology, applied in the field of resistive variable memory and improving its positive and negative current difference, can solve problems such as misreading of stored information, achieve broad application prospects, strong practicability, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

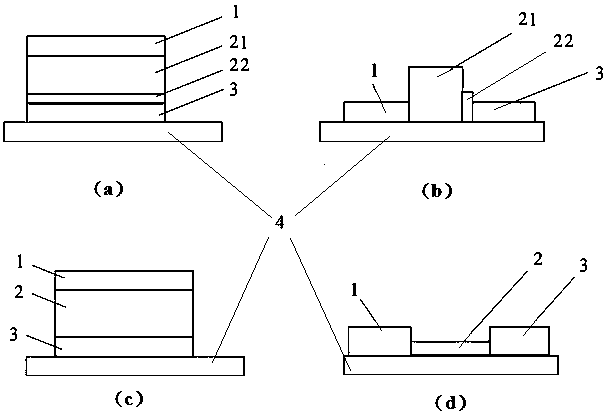

[0058] A resistive variable memory, its structure is as follows figure 1 As shown in (a), a glass substrate 4, ITO with a thickness of 200 nm is used as the first terminal electrode 3, ZnO with a thickness of 15 nm is used as the second resistive layer 22, and HfO with a thickness of 30 nm x The first resistive switch layer 21 and Ti with a thickness of 200 nm are used as the second terminal electrode 1 .

[0059] In order to increase the positive and negative current difference of the resistive variable memory, the specific manufacturing steps are as follows:

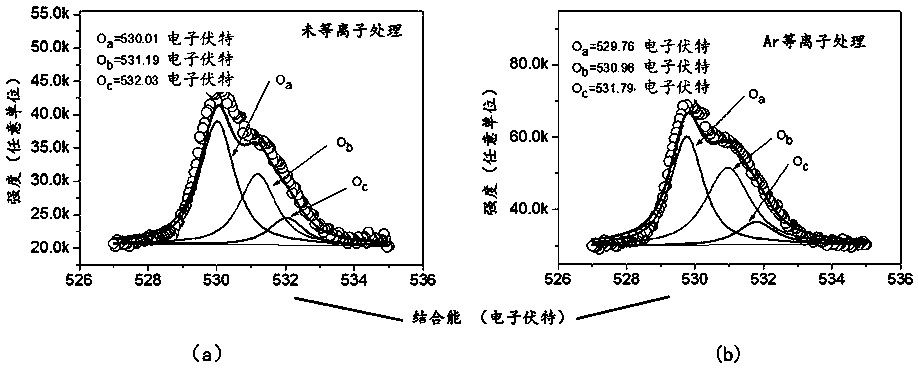

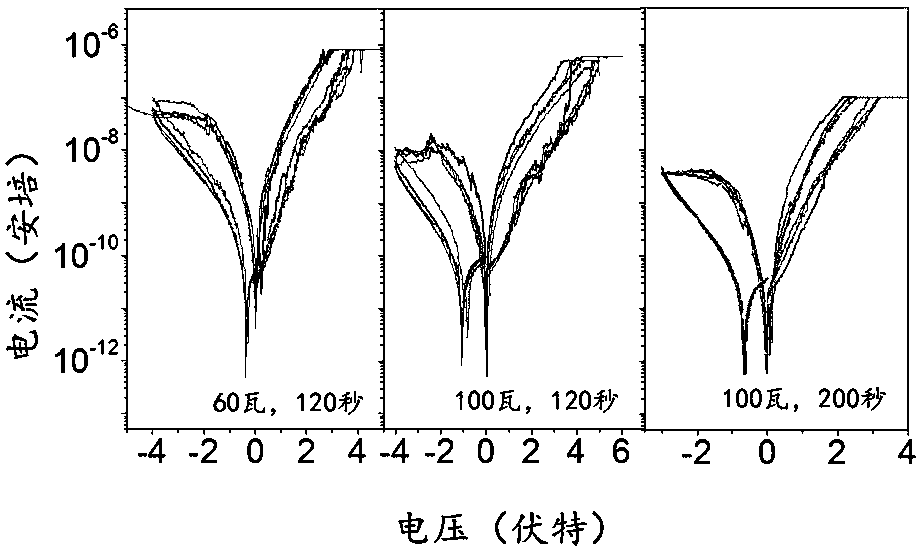

[0060] Put the glass substrate with the ITO conductive film into the vacuum chamber, and prepare 15nm ZnO as the second resistive layer 22 by magnetron sputtering; and (100 watts, 200 seconds) Ar plasma treatment of the second resistive layer 22 of ZnO with three pairs of parameters; followed by magnetron sputtering to prepare 30nm HfO x As the first resistive switch layer 21, thereby forming a double-layer storage m...

Embodiment 2

[0063] A resistive variable memory, its structure is as follows figure 1 As shown in (d), a PET substrate 4, Ti with a thickness of 200 nm is used as the first terminal electrode 3, a ZnO nanowire with a length of 10 μm and a diameter of 50 nm is used as the resistive dielectric layer 2, and the thickness is 200 nm. Ti is formed as the second terminal electrode 1 .

[0064] In order to increase the positive and negative current difference of the resistive variable memory, the specific manufacturing steps are as follows:

[0065] Sprinkle the ZnO nanowires on the PET substrate, and then make the first end electrode on the ZnO nanowires by magnetron sputtering, then use 100 watts Ar plasma to treat the ZnO nanowires for 120 seconds, and then place the ZnO nanowires on the ZnO nanowires. On the other end, the second end electrode is prepared by magnetron sputtering.

[0066] It can be seen from the test, such as Figure 4 As shown, the difference between the positive and negat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com