Method and device for stripping a gas from a gas mixture using a venturi ejector

A technology of gas mixture and liquid mixture, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., and can solve problems such as gas pressure loss and high compression energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

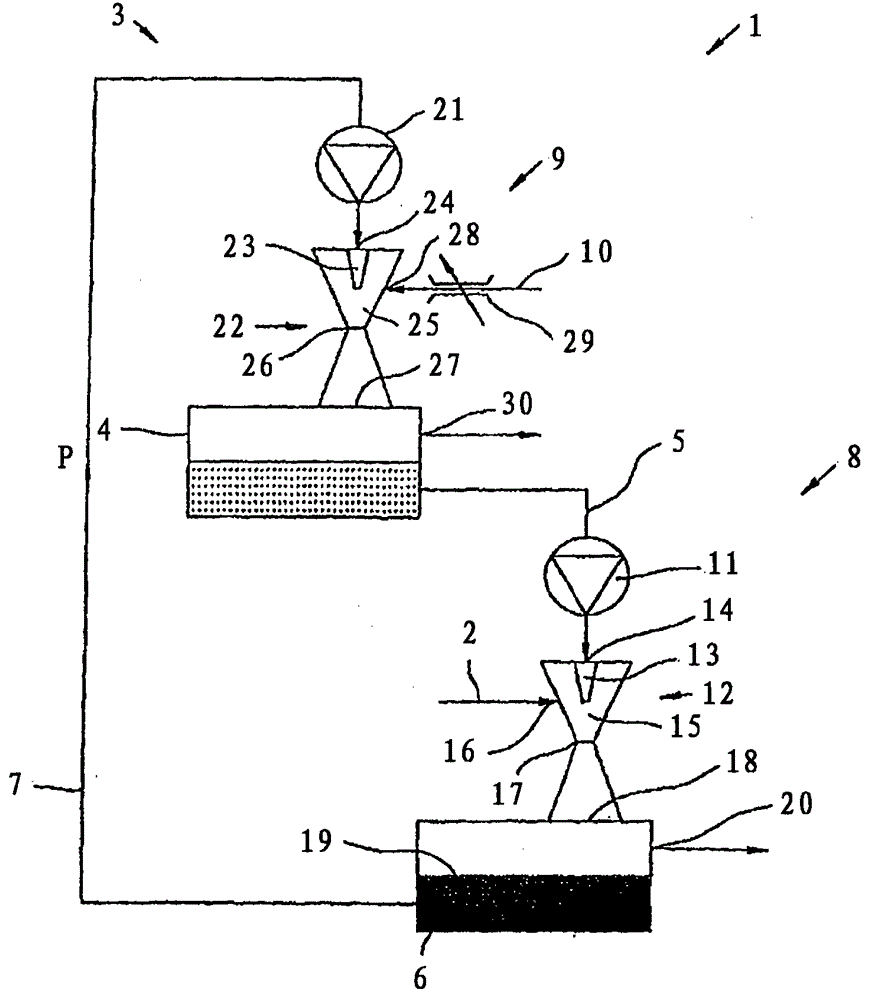

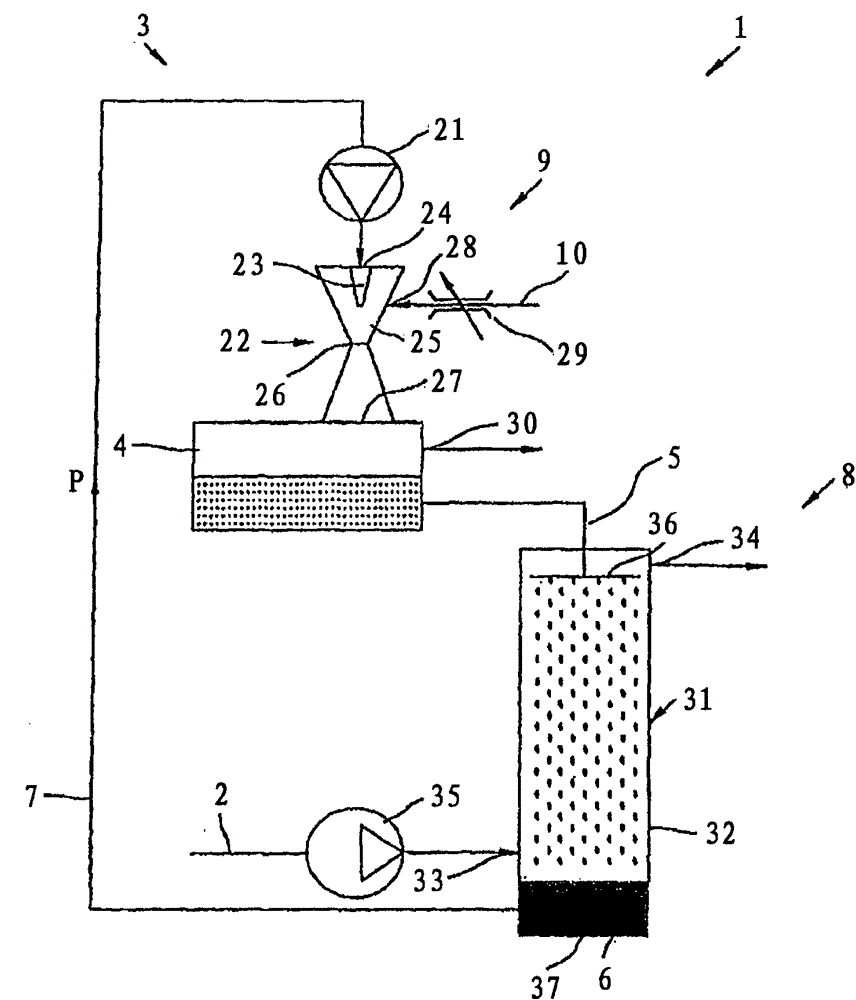

[0040] figure 1 The device 1 shown in refers to a device for extracting gas from a gas mixture supplied by a supply line 2 .

[0041] The device 1 comprises a circuit 3 to which a supply line 2 is connected, in which the liquid first adsorption medium is flowed in the direction of arrow P from the first accumulator 4 via the first duct 5 through the second accumulator 6 and via the second The tubing circulates back to the first reservoir 4 .

[0042] This first adsorption medium, when in contact with the gas mixture, exhibits the property of being able to adsorb (for example by absorption or adsorption) the gas to be extracted from said gas mixture, so that, for example, the partial pressure of the gas to be extracted in the first adsorption medium is lower than that of the gas to be extracted. The partial pressure of a gas in a gas mixture.

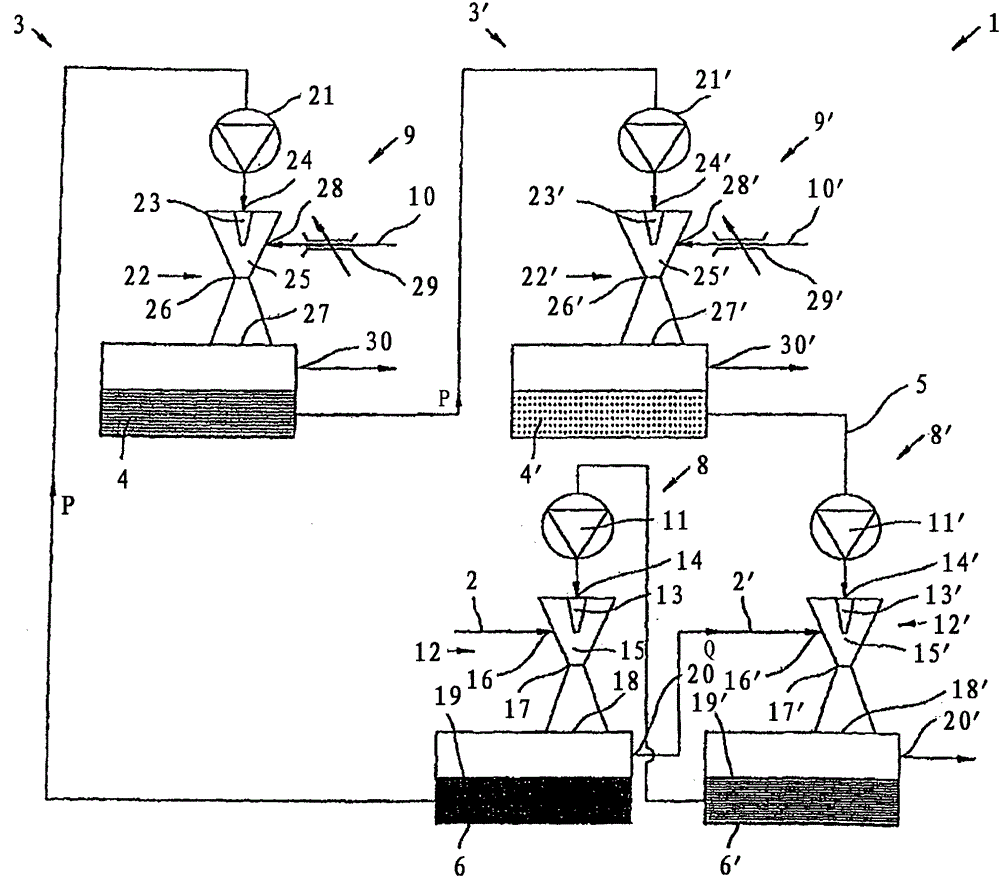

[0043] The aforementioned circuit 3 comprises two consecutive stages in flow direction P, which are respectively a purification stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com