GeOx material, preparation method thereof and application of GeOx material in lithium ion battery

A technology of germanium oxide and hollow spheres, which is applied in the field of electrochemical materials, can solve problems such as capacity fading and material structure damage, and achieve the effects of increased storage performance, stable material structure, and good lithium intercalation and delithiation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

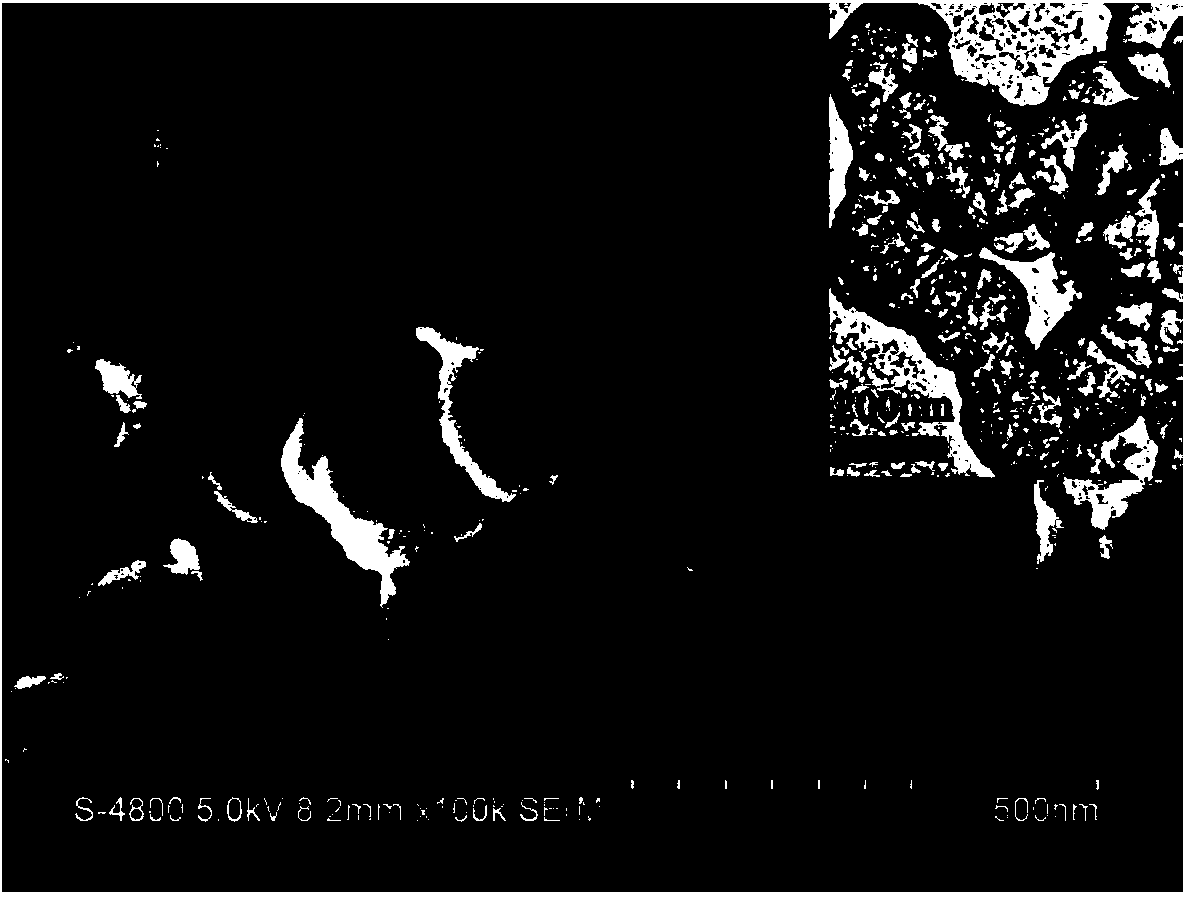

Embodiment 1

[0035] (1), add 4mmoL germanium oxide and 15mmoL sodium hydroxide to 10mL deionized water, stir for 10 minutes to form a uniform colorless solution, germanium oxide is completely dissolved, and add 1mL12mol / L concentrated hydrochloric acid to the solution;

[0036] (2) Add 31mmol of sodium borohydride (dissolved in 10mL of water first), stir magnetically until completely mixed, and the color of the solution changes from white to brown after 1 hour. Then add 20 mL of 0.5 mol / L dilute hydrochloric acid dropwise to adjust the pH of the solution to 8. Bubbles are continuously generated during this process, and the brown product gathers on the surface of the solution;

[0037] (3), transfer the solution into a 60mL autoclave lined with polytetrafluoroethylene, tighten the lid and put it in an oven, react at 120°C for 6 hours, and naturally cool to room temperature to obtain a brown-black product.

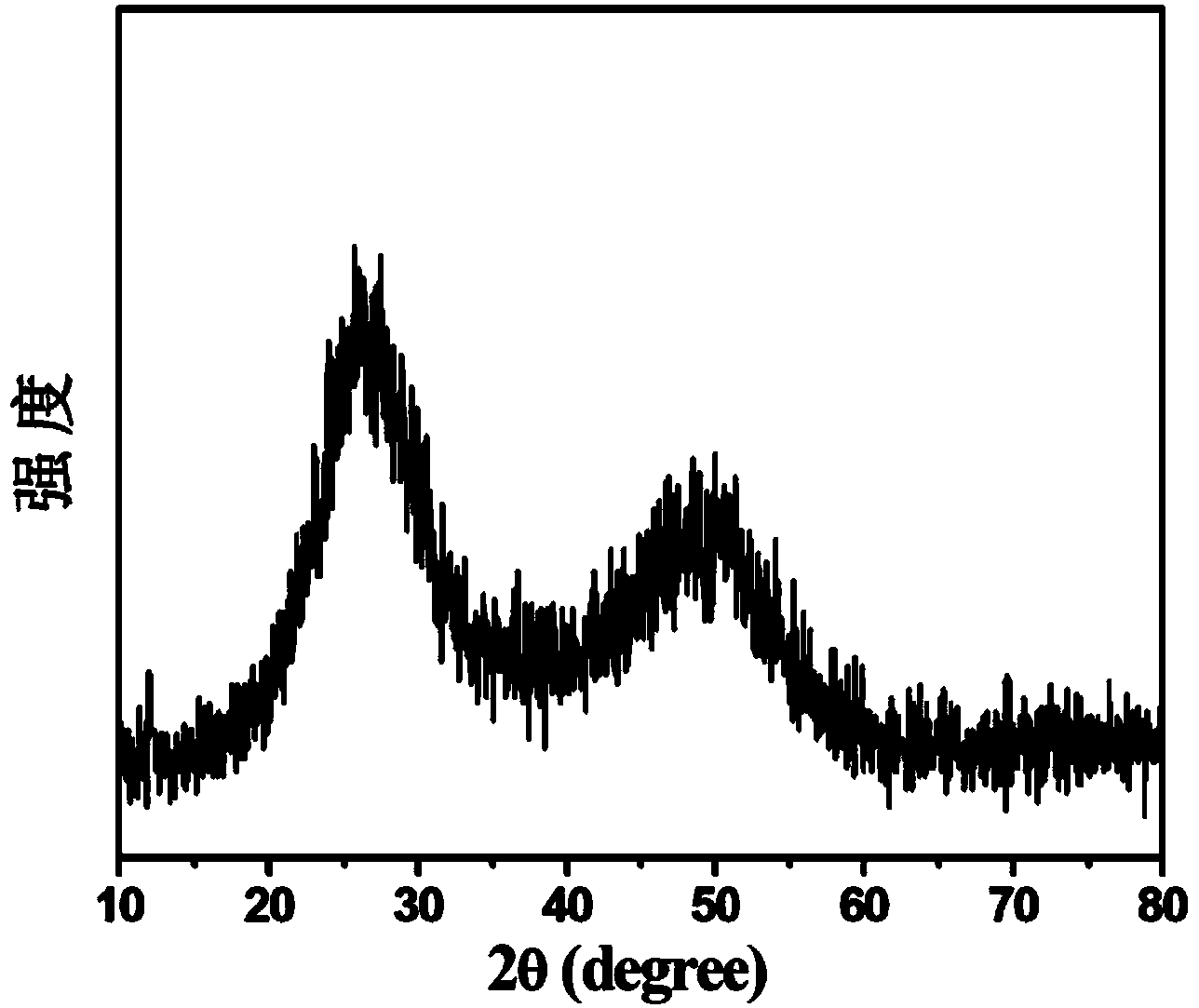

[0038] Battery test results such as image 3 , 4 shown. The first discharge is 22...

Embodiment 2

[0042] (1), add 3mmoL germanium oxide and 14mmoL sodium hydroxide to 10mL deionized water, stir for 10 minutes to form a uniform colorless solution, germanium oxide is completely dissolved, and add 0.8mL12mol / L concentrated hydrochloric acid to the solution;

[0043] (2) Add 24mmol of sodium borohydride (dissolved in 10mL of water first), stir magnetically until completely mixed, and the color of the solution changes from white to brown after 1 hour. Then add 15mL of 0.3mol / L dilute hydrochloric acid dropwise to adjust the pH of the solution to 7. Bubbles are continuously generated during the process, and the brown product gathers on the surface of the solution;

[0044](3), transfer the solution into a 60mL autoclave lined with polytetrafluoroethylene, tighten the lid and place it in an oven, react at 120°C for 8 hours, and cool naturally to room temperature to obtain a brown-black product.

[0045] The battery test results show that the first discharge is 2200mAh / g, and the ...

Embodiment 3

[0047] (1), add 4mmoL germanium oxide and 15mmoL sodium hydroxide to 10mL deionized water, stir for 10 minutes to form a uniform colorless solution, germanium oxide is completely dissolved, and add 1mL12mol / L concentrated hydrochloric acid to the solution;

[0048] (2) Add 28mmol of sodium borohydride (dissolved in 10mL of water first), stir magnetically until completely mixed, and the color of the solution changes from white to brown after 3 hours. Add 15 mL of 0.5 mol / L dilute hydrochloric acid dropwise to adjust the pH of the solution to 7. Bubbles are continuously generated during the process, and the brown product gathers on the surface of the solution;

[0049] (3), transfer the solution into a 60 mL autoclave lined with polytetrafluoroethylene, tighten the lid and place it in an oven, react at 150° C. for 6 hours, and naturally cool to room temperature to obtain a brown-black product.

[0050] The battery test results show that the first discharge is 2360mAh / g, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com