Raw soil underground cave dwelling roof vegetation plantation base structure and construction technology thereof

A kiln roof and grass-roots technology, applied in the field of traditional dwellings, to achieve the effect of improving the ecological system, overcoming the overly large area and being economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings.

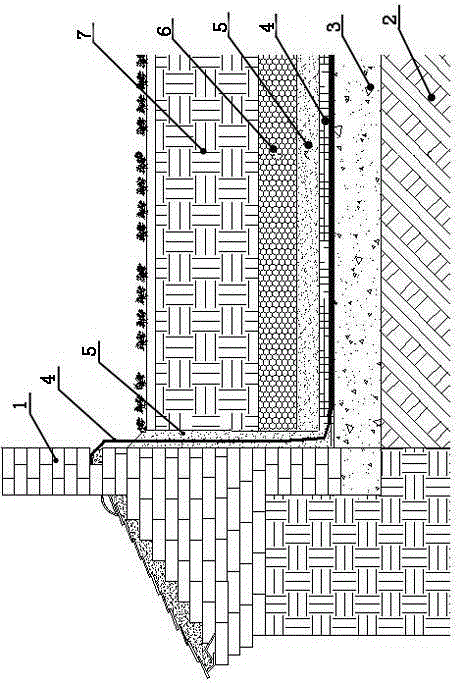

[0043] Such as figure 1 As shown, a raw soil pit kiln roof vegetation planting base structure, including a barrier wall 1, a planting base and a solid soil layer 2 on the top of the kiln, and the barrier wall 1 is arranged on the cliff surface of the solid soil layer 2 on the top of the kiln On the top, the planting base is set on the solid soil layer 2 of the kiln roof, and the planting base includes a slope-finding layer 3, a waterproof layer 4, a waterproof and protective layer 5, a water filtration layer 6 and a soil layer arranged in sequence from bottom to top. 7. The waterproof layer 4 and the waterproof and protective layer 5 both include a horizontal part and a vertical part, the horizontal part is located between the slope finding layer 3 and the water filter layer 6, and the vertical part is located between the barrier wall 1 and the planting base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com