High frequency ultrasonic energy transducer with optimized performance and manufacturing method thereof

A technology of ultrasonic transducer and manufacturing method, applied in the directions of ultrasonic/sonic/infrasonic diagnosis, ultrasonic/sonic/infrasonic Permian technology, ultrasonic/sonic/infrasonic image/data processing, etc., capable of solving problems affecting ultrasonic diagnostic instruments Diagnose the effect, affect the image quality and other problems, achieve the effect of optimizing contrast and resolution, improving echo sensitivity and spectral bandwidth, and wide bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

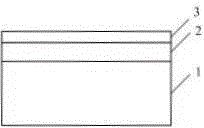

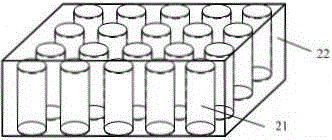

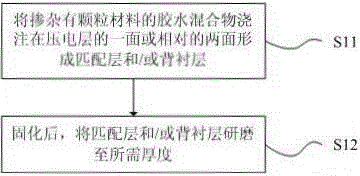

[0047] combine figure 1 , the high-frequency ultrasonic transducer with optimized performance of the present invention is described in detail, which includes: a backing layer 1, a piezoelectric layer 2, and a matching layer 3 connected in sequence, and the matching layer 3 and / or the backing layer 1 are formed by casting Deposited on the surface of the piezoelectric layer 2 by pouring the glue mixture doped with granular materials on the surface of the piezoelectric layer 2, and then grinding the matching layer 3 and / or the backing layer 1 to the desired thickness after curing , the matching layer 3 and / or the bac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com