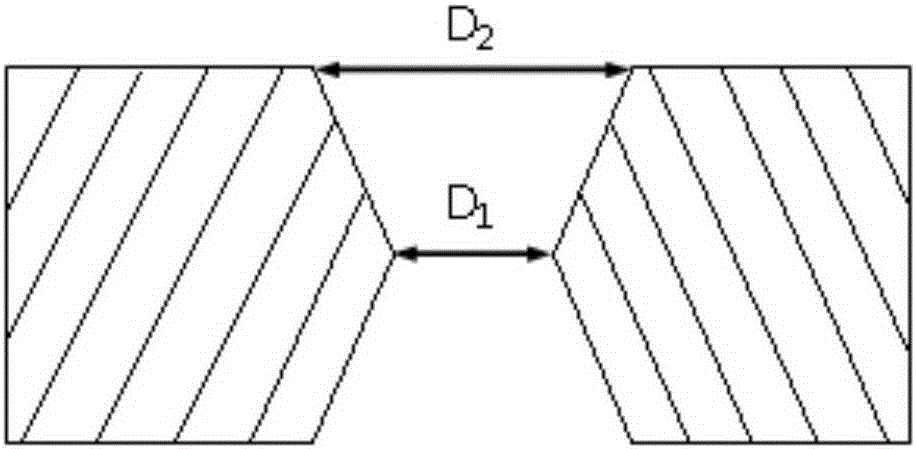

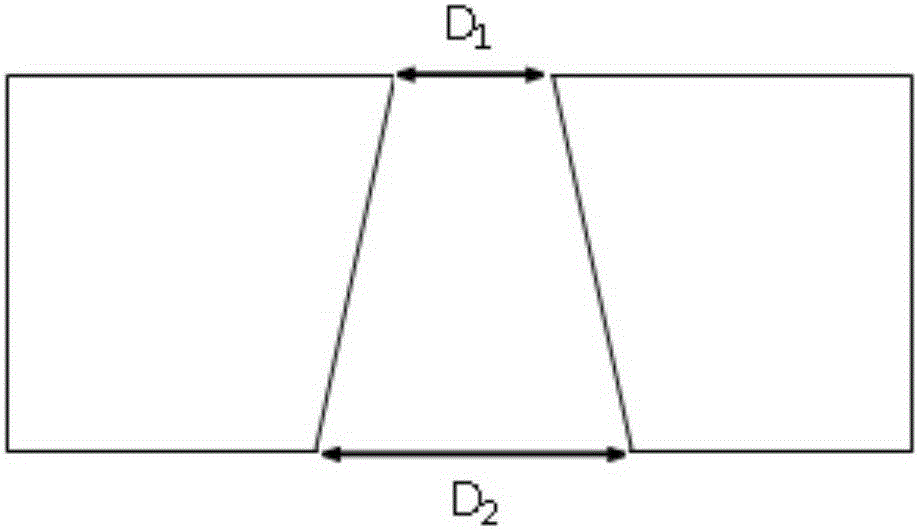

Manufacturing method for nuclear track etched membrane with single taper micropore

A technology of nuclear track etching and manufacturing method, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult operation, unsuitable for mass production, and difficult to control single-cone micropores, etc. Achieve the effect of low cost, easy implementation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

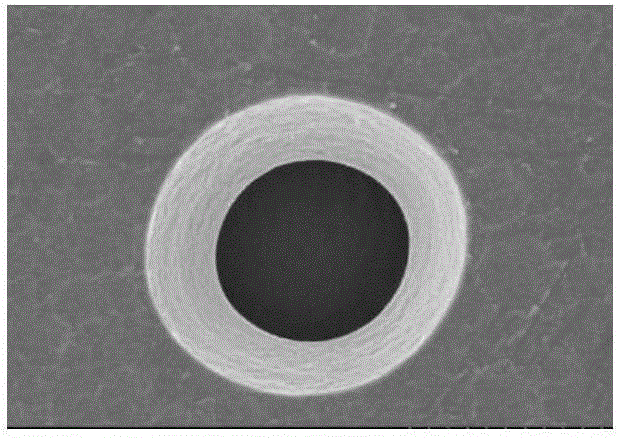

Image

Examples

Embodiment 1

[0024] This embodiment is used to illustrate the manufacturing method of the nuclear track etching film with a single tapered micropore provided by the present invention. Specific steps are as follows:

[0025] Making a double-layer film: superimposing two polyester films of the same size with a thickness of 25 μm to obtain a double-layer film;

[0026] Irradiation: On the tandem accelerator of the China Institute of Atomic Energy, a sulfur ion beam with an energy of 80-500 MeV is generated, the beam intensity is 0.1nA-1mA, and the irradiation time is 0.1-0.8 seconds on the double-layer film. The latent track density formed on the bilayer film after irradiation is 2×10 5 / cm 2 ;

[0027] Etching: Put the irradiated double-layer film into NaOH aqueous solution with a concentration of 6mol / L for etching, the etching time is 35min, and the etching temperature is 70°C;

[0028] Cleaning: use a weak acid solution (pH 2, the same below) and pure water to clean the etched double-...

Embodiment 2

[0033] This embodiment is used to illustrate the manufacturing method of the nuclear track etching film with a single tapered micropore provided by the present invention. Specific steps are as follows:

[0034] Making a double-layer film: superimpose two polypropylene films of the same size with a thickness of 18 μm to obtain a double-layer film;

[0035] Irradiation: The double-layer film was irradiated as in Example 1, and the latent track density formed on the double-layer film after irradiation was 3×10 5 / cm 2 ;

[0036] Etching: put the irradiated bilayer film in H2 with a concentration of 6mol / L 2 SO 4 solution and 0.8mol / L potassium dichromate solution for etching, the etching time is 35min, and the etching temperature is 70°C;

[0037] Cleaning: use weak acid solution and electro-pure water to clean the etched double-layer film;

[0038] Drying: Dry the cleaned double-layer film in an oven at a temperature of 70°C;

[0039] Separation of the double-layer membra...

Embodiment 3

[0042] This embodiment is used to illustrate the manufacturing method of the nuclear track etching film with a single tapered micropore provided by the present invention. Specific steps are as follows:

[0043] Making a double-layer film: superimpose two polyimide films of the same size with a thickness of 12.5 μm to obtain a double-layer film;

[0044] Irradiation: The double-layer film was irradiated as in Example 1, and the latent track density formed on the double-layer film after irradiation was 2×10 6 / cm 2 ;

[0045] Etching: put the irradiated bilayer film into KMnO with a concentration of 0.5mol / L 4 Soak in the aqueous solution for 20 minutes, and then use 1mol / L sodium hypochlorite aqueous solution for etching, the etching time is 18 minutes, and the etching temperature is 65°C;

[0046] Cleaning: use weak acid solution and high-purity water with a resistance greater than 2 megohms to clean the etched double-layer film;

[0047] Drying: Dry the cleaned double-la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com