Titanium dioxide/bismuth vanadate multiphase composite heterojunction nano photocatalytic material preparation method

A composite heterojunction and titanium dioxide technology, which is applied in the field of preparation of multi-heterojunction composite photocatalytic materials, can solve problems such as insufficient response in the visible light region, and achieve the effects of wide application range, long-lasting photocatalytic performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

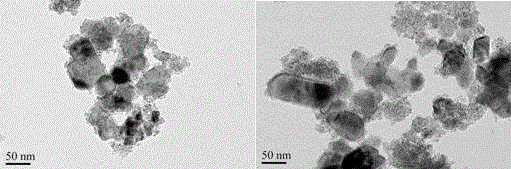

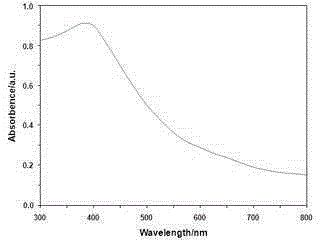

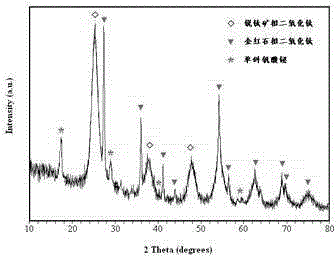

[0032] (1) Add 42 mol of distilled water to titanyl sulfate with a titanium content of 0.06 mol, stir vigorously for 30 minutes, add 0.45 mol of ammonia water dropwise, and stir vigorously at the same time, and continue stirring for 30 minutes after the dropwise addition. Wash and filter with deionized water for 4 times, dilute with 21 mol of distilled water, and stir vigorously to disperse. Add 30wt%H dropwise 2 o 2 0.66mol, and vigorously stir at the same time, and continue to stir for 60min after the dropwise addition. It was stable for 2 hours, and a yellow transparent 0.15 mol / L peroxotitanic acid solution A was obtained.

[0033] (2) 0.01g of TritonX-100, 0.16mol of absolute ethanol, after mixing, magnetically stir for 5min. Then weigh 0.3 g of rutile powder, slowly add it into the beaker in small amounts several times, stir strongly with magnetic force, and after 20 minutes, the suspension dispersion liquid B of rutile is obtained.

[0034] (3) Bi (NO 3 ) 3 ·5H 2...

Embodiment 2

[0038] (1) Add 42 mol of distilled water to titanyl sulfate with a titanium content of 0.06 mol, stir vigorously for 30 minutes, add 0.45 mol of ammonia water dropwise, and stir vigorously at the same time, and continue stirring for 30 minutes after the dropwise addition. Wash and filter with deionized water for 4 times, dilute with 21 mol of distilled water, and stir vigorously to disperse. Add 30wt%H dropwise 2 o 20.66mol, and vigorously stir at the same time, and continue to stir for 60min after the dropwise addition. It was stable for 2 hours, and a yellow transparent 0.15 mol / L peroxotitanic acid solution A was obtained.

[0039] (2) Bi (NO 3 ) 3 ·5H 2 O-acetic acid solution to make Bi(NO 3 ) 3 ·5H 2 O is completely dissolved; then configure VO(acac) at 0.03mol / L 2 -Acetylacetone solution to make VO(acac) 2 completely dissolved. Finally, the two metal precursors were mixed according to the stoichiometric molar ratio Bi / V=1:1, and stirred vigorously for 1.5 h to...

Embodiment 3

[0043] (1) Bi (NO 3 ) 3 ·5H 2 O-acetic acid solution to make Bi(NO 3 ) 3 ·5H 2 O is completely dissolved; then configure VO(acac) at 0.03mol / L 2 -Acetylacetone solution to make VO(acac) 2 completely dissolved. Finally, the two metal precursors were mixed according to the stoichiometric molar ratio Bi / V=1:1, and stirred vigorously for 1.5 h to obtain a dark blue-green transparent 0.028 mol / L solution C.

[0044] (2) 6g of C was coated on the surface of a clean heat-resistant substrate, then heated to 500°C, kept for 1h, and cooled to room temperature.

[0045] (3) Carry out the methylene blue decolorization test, irradiate 3mg / L methylene blue with 254nm ultraviolet light for 5min, and the decolorization rate of three consecutive concentrations reaches 51.14%, 47.83% and 37.12%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com