Method for laying electrochemistry desalting external anode through magnesium phosphate cement and carbon fiber sheet

A technology of magnesium phosphate cement and carbon fiber cloth, which is applied in the field of electrochemical desalination of reinforced concrete structures, can solve problems such as blocking chloride ions and reducing the effect of desalination, and achieves the effects of prolonging service life, reducing material costs, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

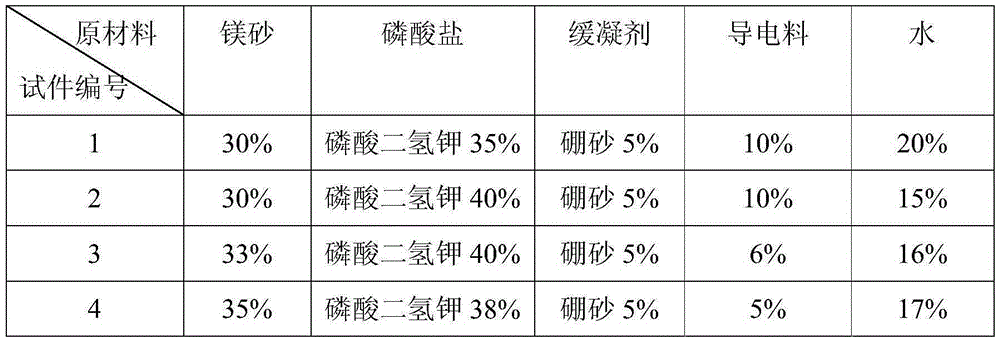

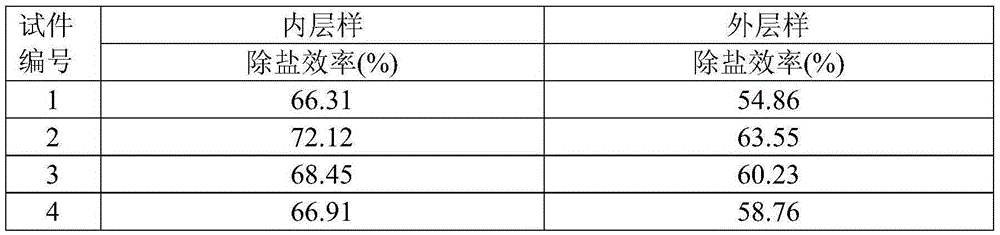

[0038] The size of the reinforced concrete (mortar) specimen used in the test is 300mm×300mm×120mm, and the mix ratio is water: cement: sand = 0.5:1:3, where Cl - It is directly mixed and added during molding, and the dosage of sodium chloride is 4% of the cement mass. The steel bars are smooth round steel bars of Φ8mm×320mm, and the rust on the surface of the steel bars is removed by grinding with sandpaper, and 4 bars are buried in each test piece. Distilled water and calcium hydroxide are used when preparing saturated lime water as an electrolyte solution. The material ratio of magnesium phosphate cement used in the preparation of each test piece is shown in Table 1. After the specimen is cured to 28d age under standard conditions ((20±2)℃, relative humidity 95%), connect the copper wires pre-embedded at the carbon fiber cloth of the specimen and the smooth round steel bars to the positive and negative terminals of the DC stabilized power supply respectively. The poles ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com