Highly-waterproof water-soluble polyurethane resin and preparation method thereof

A water-soluble polyurethane and water-resistant technology, applied in the field of water-soluble polyurethane resin, can solve problems such as reducing water resistance, and achieve the effects of low production risk, good water resistance and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

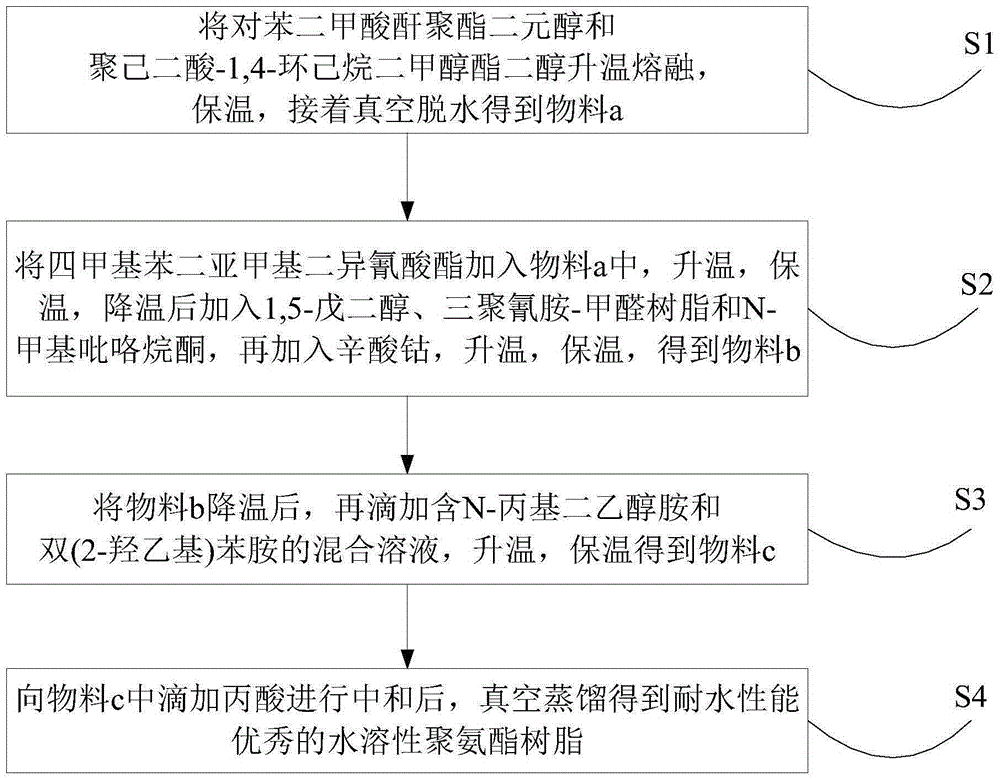

[0029] refer to figure 1 , a kind of high water resistance water-soluble polyurethane resin preparation method that the present invention proposes, comprises the following steps:

[0030] S1. Warm up and melt terephthalic anhydride polyester diol and polyadipate-1,4-cyclohexanedimethanol ester diol, keep warm, and then vacuum dehydrate to obtain material a;

[0031] S2. Add tetramethylxylylene diisocyanate to material a, heat up, keep warm, add 1,5-pentanediol, melamine-formaldehyde resin and N-methylpyrrolidone after cooling down, then add cobalt octanoate, and heat up , heat preservation, to obtain material b;

[0032] S3. After cooling down the temperature of material b, add dropwise a mixed solution containing N-propyldiethanolamine and bis(2-hydroxyethyl)aniline, heat up, and keep warm to obtain material c;

[0033] S4. Add propionic acid dropwise to the material c for neutralization, and vacuum distill to obtain a highly water-resistant water-soluble polyurethane resin...

Embodiment 1

[0036] A kind of high water resistance water-soluble polyurethane resin preparation method that the present invention proposes, comprises the following steps:

[0037] S1. Heat 30 parts of terephthalic anhydride polyester diol and 16 parts of polyadipate-1,4-cyclohexanedimethanol diol to 130°C in parts by weight, keep it warm for 4.5 hours, and then vacuum dehydrate to obtain material a;

[0038] S2. Add 25 parts of tetramethylxylylene diisocyanate to material a, raise the temperature to 100°C, keep it warm for 2 hours, add 4 parts of 1,5-pentanediol and 3 parts of melamine-formaldehyde resin after cooling down to 55°C and 25 parts of N-methylpyrrolidone, then add 0.2 parts of cobalt octoate, heat up to 87°C, and keep the temperature for 3.2 hours to obtain material b;

[0039] S3. After cooling material b to 40°C, add dropwise a mixed solution containing N-propyldiethanolamine and bis(2-hydroxyethyl)aniline, wherein the mixed solution consists of 3 parts of N-propyldiethanol...

Embodiment 2

[0042] A kind of high water resistance water-soluble polyurethane resin preparation method that the present invention proposes, comprises the following steps:

[0043] S1. Heat 33 parts of terephthalic anhydride polyester diol and 13 parts of polyadipate-1,4-cyclohexanedimethanol diol to 160°C in parts by weight, keep it warm for 3 hours, and then vacuum dehydrate to obtain the material a;

[0044] S2. Add 28 parts of tetramethylxylylene diisocyanate to material a, raise the temperature to 90°C, keep it warm for 3 hours, add 6 parts of 1,5-pentanediol and 2 parts of melamine-formaldehyde resin after cooling down to 45°C and 28 parts of N-methylpyrrolidone, then add 0.1 part of cobalt octoate, heat up to 90°C, and keep the temperature for 2.5 hours to obtain material b;

[0045] S3. After cooling material b to 45°C, add dropwise a mixed solution containing N-propyldiethanolamine and bis(2-hydroxyethyl)aniline, wherein the mixed solution consists of 2 parts of N-propyldiethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com