A kind of preparation method of cage silicone hybrid star polyester soft PVC plasticizer

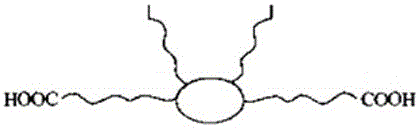

A silicone and plasticizer technology, applied in the field of preparation and modification of functional polymer materials, can solve problems such as increasing low-temperature impact resistance, achieve enhanced low-temperature impact resistance, prevent plasticizer migration, and have good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of cage silicone hybrid star polyester soft PVC plasticizer, its preparation steps are as follows:

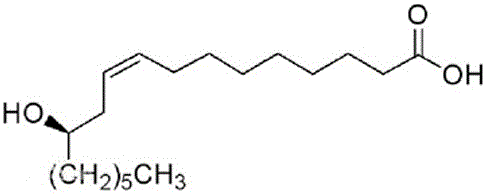

[0033] S1, ricinoleic acid is subjected to cracking and oxidation through ozone oxidation, and Renay-Ni catalytic hydrogenation reaction to obtain nonanol acid and 1,3-dihydroxynonanediol;

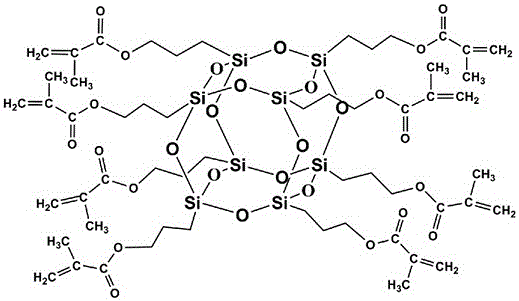

[0034] S2. The vertex group of octamethacryloxypropyl cage silsesquioxane undergoes an ester hydrolysis reaction in aqueous sulfuric acid solution, and stirs and refluxes for 4 hours to obtain octapropanol cage silsesquioxane;

[0035] S3, the nonanol acid obtained in step S1 and 1,3-dihydroxynonanediol and the octapropanol-based cage silsesquioxane obtained in step S2 are 70:10:20 in mass ratio with dimer acid Mix to obtain a mixed solution;

[0036] S4, adding esterification reaction catalyst heteropolyacid PW to the mixed solution prepared in step S3 12 / SiO 2 And dehydrating agent DCC, reflux reaction for 2~6 hours, to obtain cage silicone hybrid s...

Embodiment 2

[0039] A kind of preparation method of cage silicone hybrid star polyester soft PVC plasticizer, its preparation steps are as follows:

[0040] S1, ricinoleic acid is subjected to cracking and oxidation through ozone oxidation, and Pd / C catalytic hydrogenation reaction to obtain nonanol acid and 1,3-dihydroxynonanediol;

[0041] S2. The vertex group of octamethacryloyloxypropyl cage silsesquioxane undergoes an ester hydrolysis reaction in aqueous sodium hydroxide solution, and stirs and refluxes for 2 hours to obtain octapropanol cage silsesquioxane alkyl;

[0042] S3, the nonanol acid obtained in step S1 and 1,3-dihydroxynonanediol and the octapropanol-based cage silsesquioxane obtained in step S2 are 70:20:10 in mass ratio with dimer acid Mix to obtain a mixed solution;

[0043] S4, adding esterification reaction catalyst heteropolyacid PW to the mixed solution prepared in step S3 12 / SiO 2And dehydrating agent DCC, reflux reaction for 2~6 hours, to obtain cage silicone ...

Embodiment 3

[0045] A kind of preparation method of cage silicone hybrid star polyester soft PVC plasticizer, its preparation steps are as follows:

[0046] S1, ricinoleic acid is subjected to cracking and oxidation through ozone oxidation, and Pd / C catalytic hydrogenation reaction to obtain nonanol acid and 1,3-dihydroxynonanediol;

[0047] S2. The vertex group of octamethacryloxypropyl cage silsesquioxane undergoes an ester hydrolysis reaction in aqueous sulfuric acid solution, and stirs and refluxes for 4 hours to obtain octapropanol cage silsesquioxane;

[0048] S3, the nonanol acid obtained in step S1 and 1,3-dihydroxynonanediol and the octapropanol-based cage silsesquioxane obtained in step S2 are 80:10:10 in mass ratio with dimer acid Mix to obtain a mixed solution;

[0049] S4, adding esterification reaction catalyst heteropolyacid PW to the mixed solution prepared in step S3 12 / SiO 2 And dehydrating agent DCC, reflux reaction for 2~6 hours, to obtain cage silicone hybrid star ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com