Method for manufacturing high-performance bearing retainer

A bearing cage and manufacturing method technology, applied in bearing components, shafts and bearings, mechanical equipment and other directions, can solve the problems of increased friction, wear and heat, wear, low operating temperature, etc., to improve service life and performance, process Well-arranged, high-quality finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

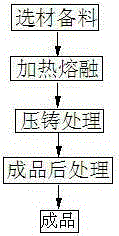

Image

Examples

Embodiment 1

[0016] The specific manufacturing steps of the high-performance bearing cage mentioned in the present invention are as follows:

[0017] a) Material selection and preparation, the raw material is aluminum-magnesium alloy ZL101, and rare earth lanthanum is added to the raw material, and the amount of rare earth added is controlled at 4.5%;

[0018] b) heating and melting, the melting temperature of the raw material is controlled at 540°C-580°C, the heating rate is controlled at 70°C-80°C / min, and the raw material is melted and subjected to constant temperature treatment at 540°C for 2-2.5 hours;

[0019] c) Die-casting treatment, the equipment adopts hot chamber die-casting machine, the material of the mold is heat-resistant mold steel, and its preheating temperature is controlled at 300°C-320°C; during the die-casting process, the injection specific pressure is controlled at 40-45MPa, and the injection speed is controlled At 2cm / s, the holding time is controlled at 2 minutes; ...

Embodiment 2

[0022] The specific manufacturing steps of the high-performance bearing cage mentioned in the present invention are as follows:

[0023] a) Material selection and preparation, the raw material is aluminum-magnesium alloy ZL104, and rare earth lanthanum is added to the raw material, and the amount of rare earth added is controlled at 4.6%;

[0024] b) Heating and melting, the melting temperature of the raw material is controlled at 560°C-600°C, the heating rate is controlled at 80°C-90°C / min, after the raw material is melted, it is subjected to constant temperature treatment at a temperature of 550°C for 3 hours;

[0025] c) Die-casting treatment, the equipment adopts hot chamber die-casting machine, the material of the mold is heat-resistant mold steel, and its preheating temperature is controlled at 320°C-330°C; during the die-casting process, the injection specific pressure is controlled at 42-46MPa, and the injection speed is controlled At 2.5cm / s, the holding time is contr...

Embodiment 3

[0028] The specific manufacturing steps of the high-performance bearing cage mentioned in the present invention are as follows:

[0029] a) Material selection and preparation, the raw material is aluminum-magnesium alloy ZL101A, and rare earth rhenium is added to the raw material, and the amount of rare earth added is controlled at 4.5%;

[0030] b) Heating and melting, the melting temperature of the raw material is controlled at 550°C-570°C, the heating rate is controlled at 80°C-100°C / min, after the raw material is melted, it is subjected to constant temperature treatment at a temperature of 560°C for 3 hours;

[0031] c) Die-casting treatment, the equipment adopts hot chamber die-casting machine, the material of the mold is heat-resistant mold steel, and its preheating temperature is controlled at 310°C-320°C; during the die-casting process, the injection specific pressure is controlled at 40-44MPa, and the injection speed is controlled At 3cm / s, the holding time is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com