Biomass fuel combustion device

A biomass fuel and combustion device technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of low combustion efficiency, heat loss, complex structure, etc., to improve combustion efficiency, reduce occupied space, avoid coking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

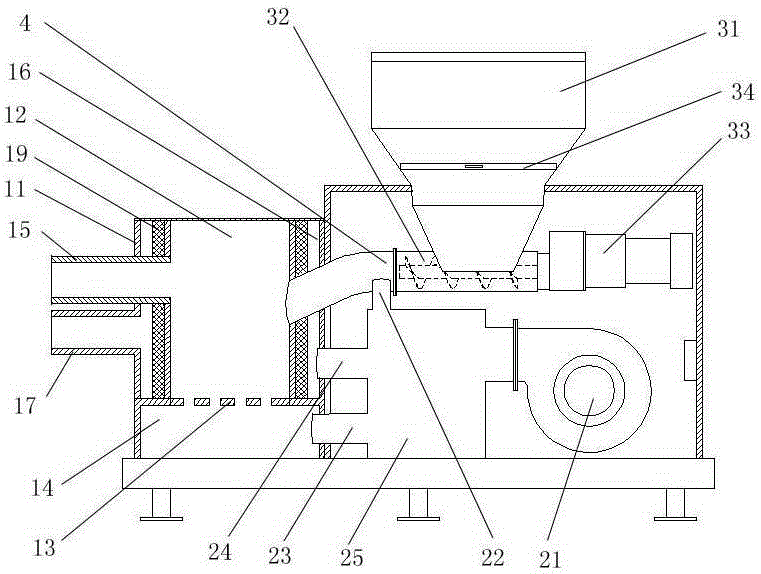

[0028] like figure 1 As shown, the biomass fuel combustion device provided in this embodiment includes a combustion chamber, a blast device, and a feeding device, and the charging device includes a feeding pipe 4; the combustion chamber includes a casing 11, a furnace 12, and a fire grate 13 , ash box 14 and fire outlet pipe 15; an air-cooled interlayer 16 is provided between the shell 11 and the furnace 12; a fire grate 13 and ash box 14 are arranged below the furnace 12; the fire outlet pipe 15 is arranged on the combustion chamber One side of the chamber communicates with the furnace 12, and stretches out after passing through the air-cooled interlayer 16 and the shell 11;

[0029] Described blower device comprises fan 21, air duct I22, air duct II23, air duct III24, and described fan 21 communicates with air duct I22, air duct II23 and air duct III24 respectively; 4 connected; the air duct II 23 communicates with the ash box 14; the air duct III 24 communicates with the a...

Embodiment 2

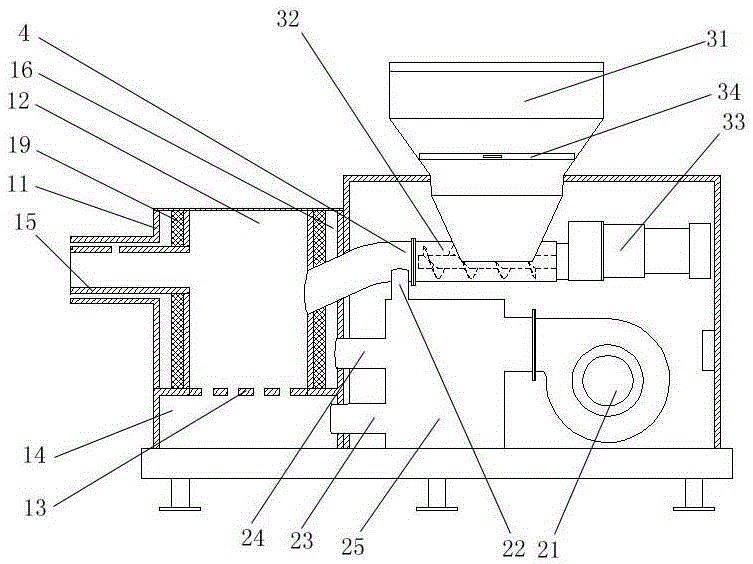

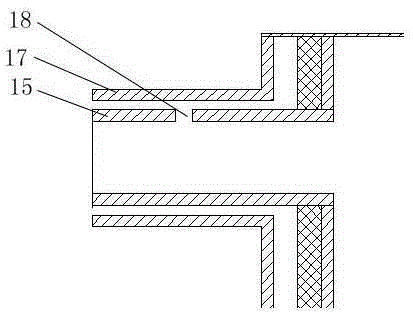

[0035] like figure 2 , 3 As shown, the biomass fuel combustion device provided in this embodiment includes a combustion chamber, a blast device, and a feeding device, and the charging device includes a feeding pipe 4; the combustion chamber includes a casing 11, a furnace 12, and a fire grate 13 , ash box 14 and fire outlet pipe 15; an air-cooled interlayer 16 is provided between the shell 11 and the furnace 12; a fire grate 13 and ash box 14 are arranged below the furnace 12; the fire outlet pipe 15 is arranged on the combustion chamber One side of the chamber communicates with the furnace 12, and stretches out after passing through the air-cooled interlayer 16 and the shell 11;

[0036] Described blower device comprises fan 21, air duct I22, air duct II23, air duct III24, and described fan 21 communicates with air duct I22, air duct II23 and air duct III24 respectively; 4 connected; the air duct II 23 communicates with the ash box 14; the air duct III 24 communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com