Natural gas heat treatment furnace

A heat treatment furnace, natural gas technology, applied in the direction of waste heat treatment, furnace, furnace type, etc., can solve the problems of uneven heating, high cost, increased energy consumption, etc., achieve good heat insulation performance, long service life, and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

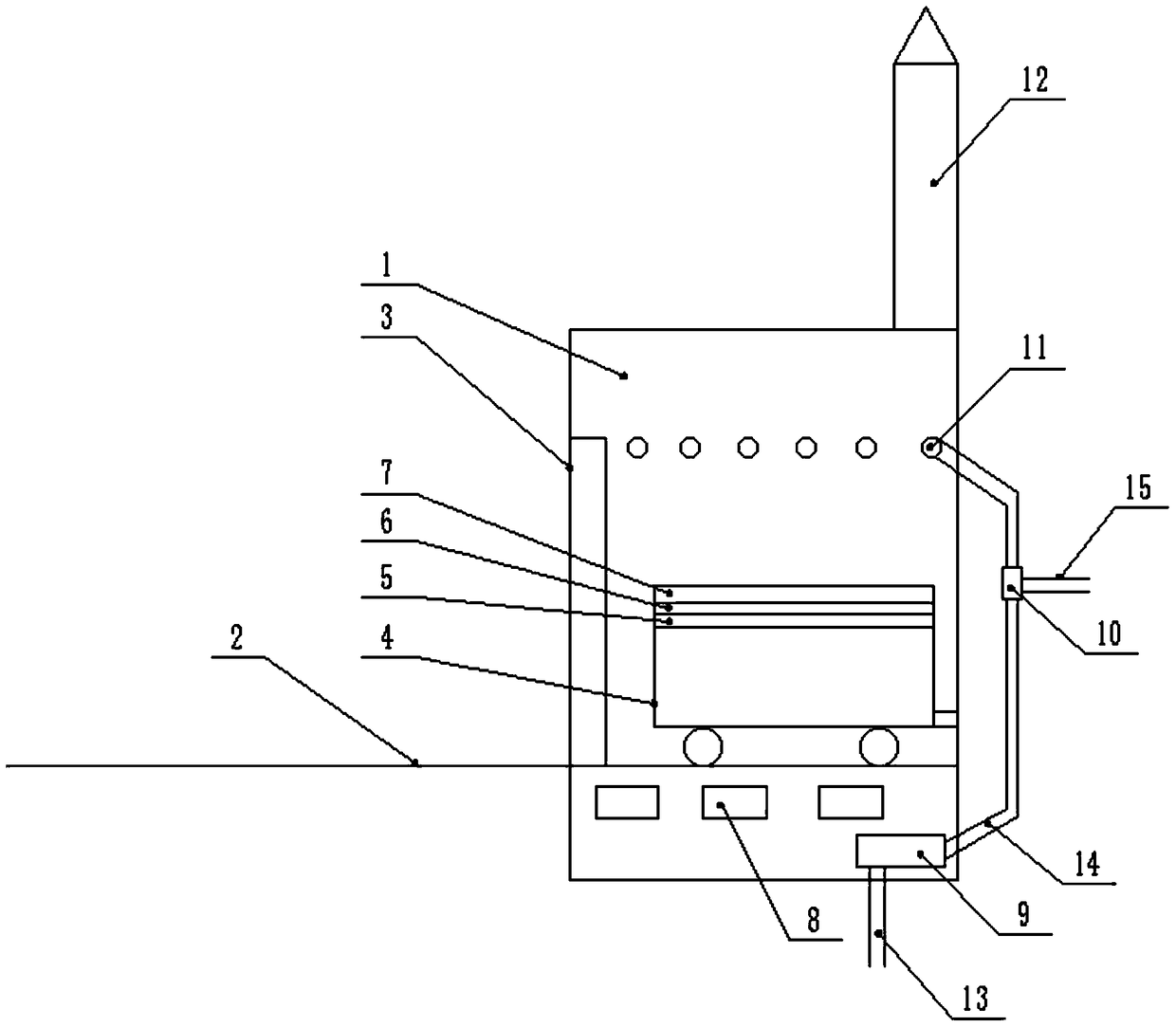

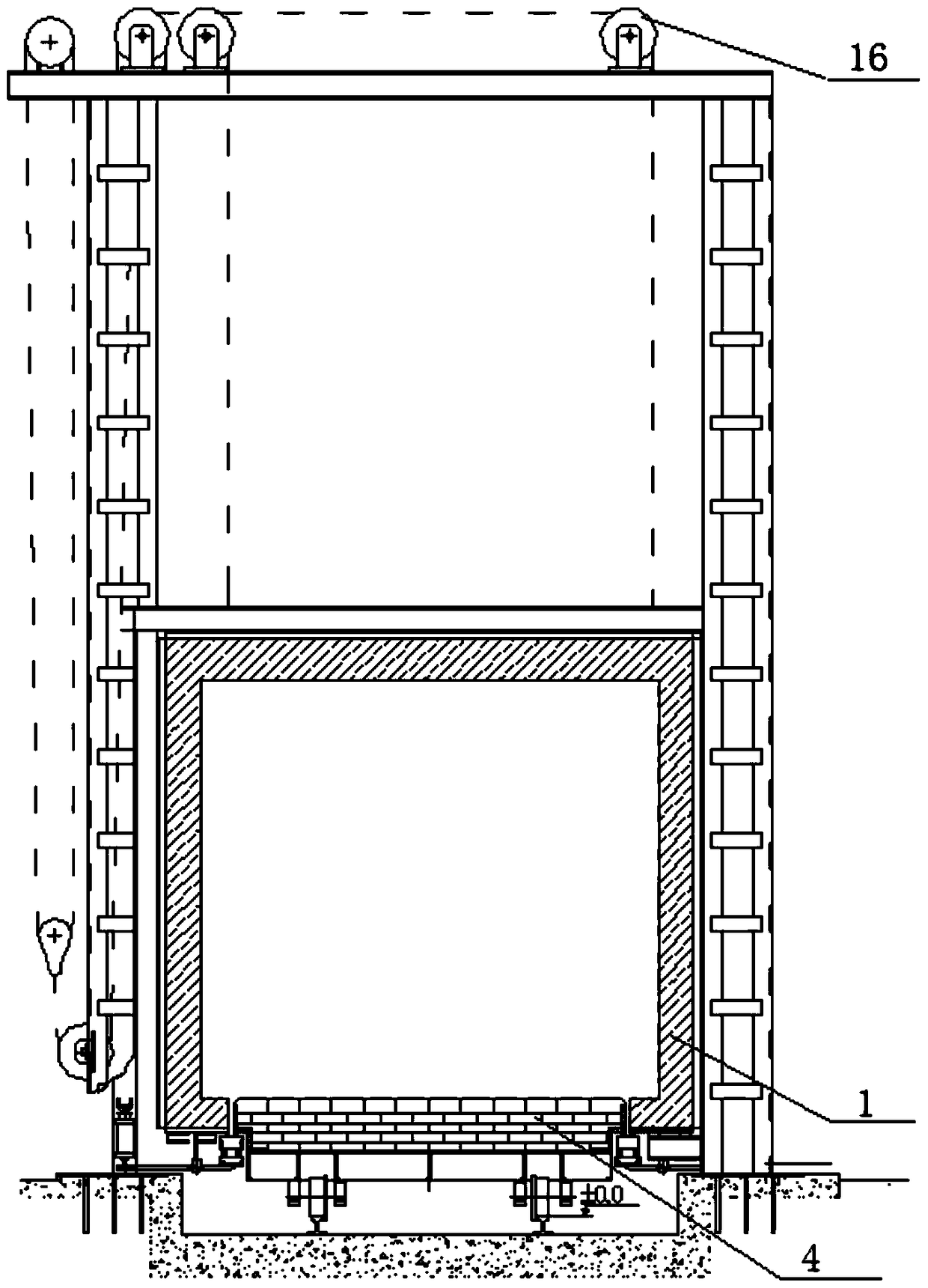

[0023] Such as Figure 1-Figure 2 As shown, the natural gas heat treatment furnace includes a furnace body 1, a furnace door 3 is provided on the front side of the furnace body 1, a horizontal guide rail 2 is provided at the bottom of the furnace body 1, the horizontal guide rail 2 extends to the outside of the furnace body, and a trolley is provided on the guide rail 2 4. Lay refractory parts on the trolley 4; evenly arrange 3 flue openings 8 on the side wall of the bottom of the furnace body 1; change the existing flue openings at the back (relative to the furnace door) to the bottom of the furnace and evenly Three flue openings are provided, which overcomes the defect of partial overheating of the side flue openings.

[0024] An air displacer 9 is installed in the flue at the bottom of the furnace body 1, and the air inlet pipe 13 of the air displacer 9 is for cold air to enter. The air displacer 9 uses the waste heat of the flue to preheat the cold air to form hot air. The ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com