Method used for detecting air purifying material purification efficiency

An air purification material and purification material technology, applied in the direction of analysis materials, measuring devices, instruments, etc., can solve the problems of damage to the paint film, large instrument volume, high contact probability, etc., and achieve the effect of easy operation and accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

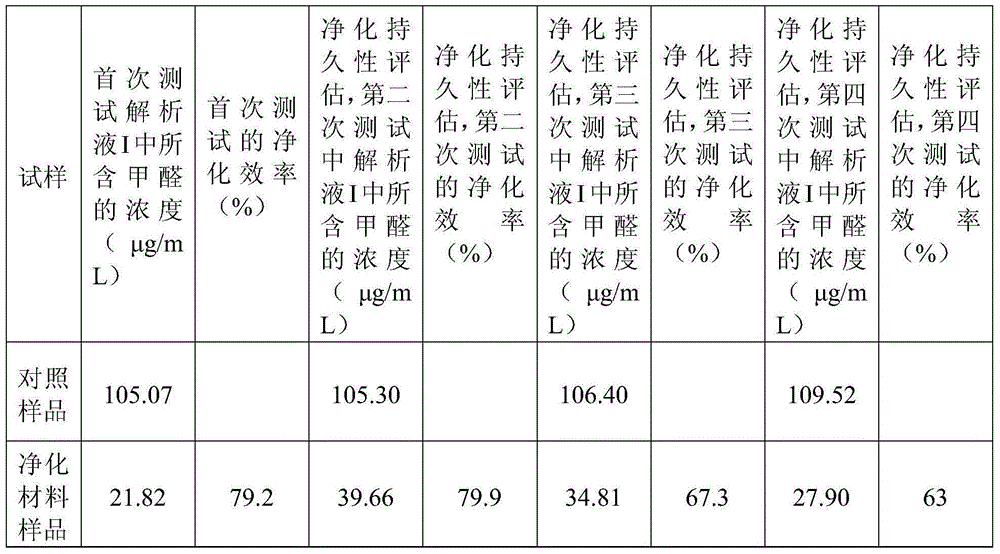

[0070] In this embodiment, the following method is used to test the purification efficiency of air purification materials on formaldehyde, including the following steps:

[0071] (1) Preparation of purification material samples and control samples: Coat the commercially available aldehyde-removing air purification materials on four 10cm×15cm polyethylene (PE) panels, and the amount is according to the theoretical coating amount provided by the product, and the temperature is (20 Dry for 7 days under the conditions of ±2)°C and relative humidity of (50±10)% as the purification material sample; use the polyethylene (PE) board not coated with commercially available dealdehyde air purification material as the control sample;

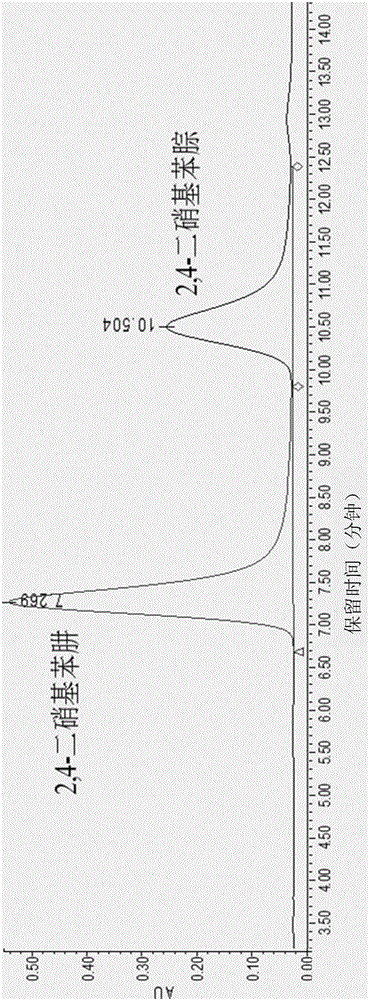

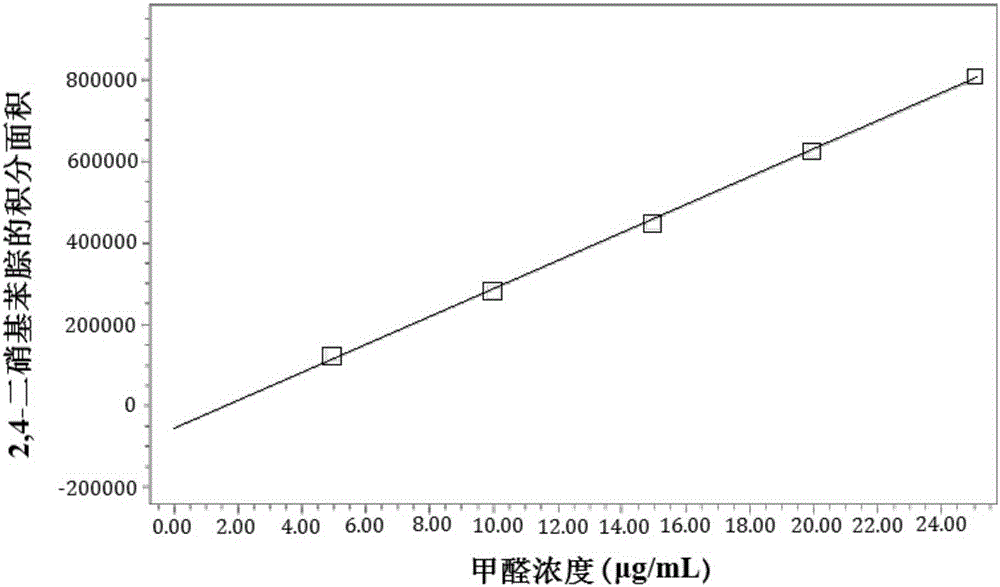

[0072] (2) Sample test: Choose a desiccator as a closed container, with a specification of 300mm. Place 6g of composite microcrystalline bamboo charcoal ceramic adsorbent in the bottom crystallization dish and flatten it. Place a sample plate coated with aldehyd...

Embodiment 2

[0088] In this embodiment, the influence of the application of different adsorption materials on the measured purification efficiency is investigated, and the method is as follows:

[0089] In the test method of this embodiment, composite microcrystalline bamboo charcoal ceramics, activated carbon, zeolite, silica gel, and molecular sieves were selected as adsorbent materials, and the test as described in Example 1 was performed respectively, and the test was repeated 4 times (different from the purification durability evaluation test , The repeated test is 4 parallel tests on the sample), the results are shown in Table 2.

Embodiment 3

[0096] In this embodiment, the following method is used to test the purification efficiency of air purification materials on formaldehyde, including the following steps:

[0097] (1) Preparation of purification material samples and control samples: The commercially available de-aldehyde air purification materials were coated on four 10cm×15cm polyethylene (PE) panels, and the amount was in accordance with the theoretical coating amount provided by the product, and the temperature was (20 Dry for 5 days under the condition of ±2)℃ and humidity of (50±10)% as a sample of purification material; use a polyethylene (PE) board not coated with a commercially available de-aldehyde air purification material as a control sample;

[0098] (2) Sample test: A desiccator is used as a closed container, with a specification of 300mm (. 6g of composite microcrystalline bamboo charcoal ceramic absorbent material is placed in the bottom crystallization dish and flattened. A sample plate coated with al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com