Carbon-silicon composite material and preparation method thereof

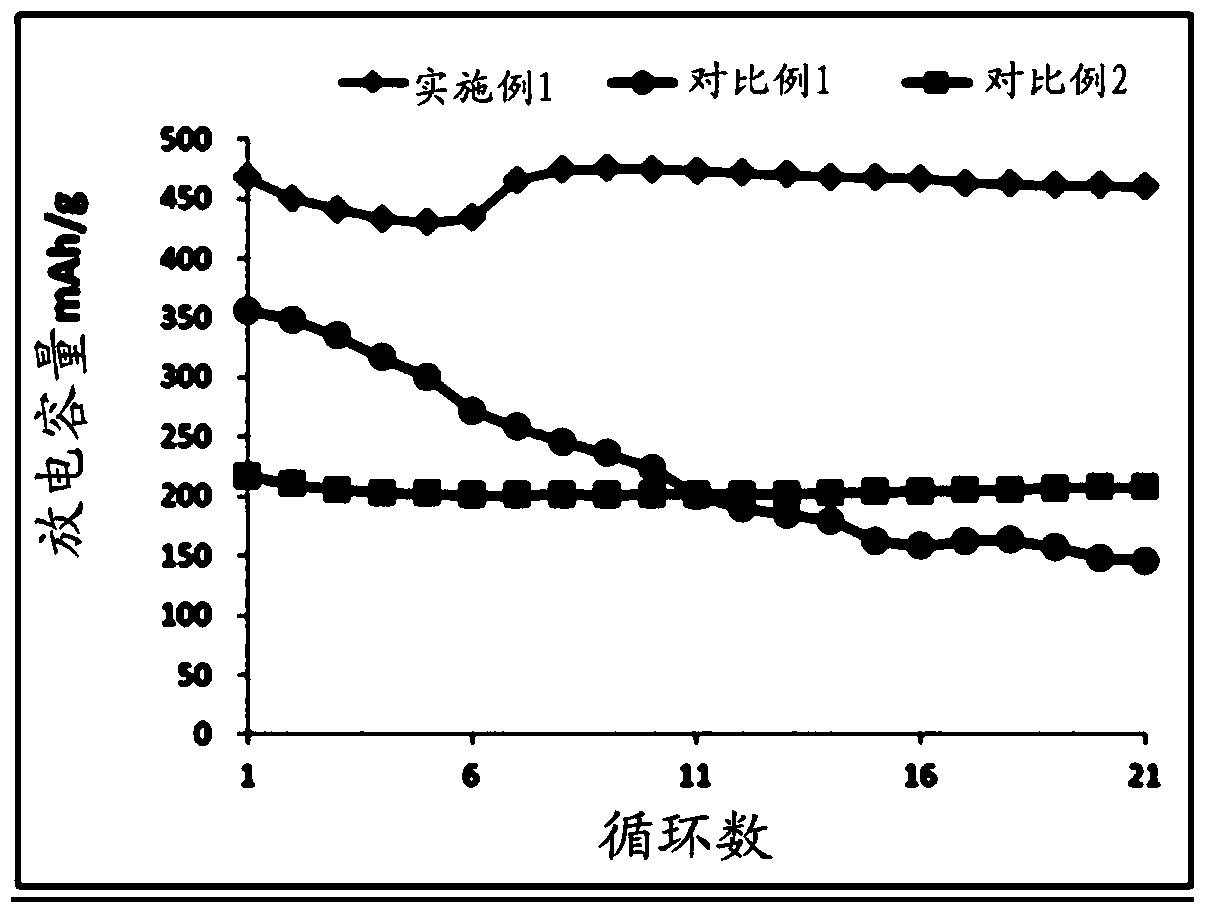

A technology of silicon composite materials and raw materials, applied in electrode manufacturing, electrode heat treatment, non-aqueous electrolyte battery electrodes, etc., can solve the problems of charging capacity and capacity reduction, and achieve the effect of increasing charging capacity and capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Preparation of silicon-polymer carbide particles

[0102] A silicon slurry was prepared by dispersing 1 g of silicon particles having an average particle size of 50 nm in 9 g of N-methyl-2-pyrrolidone (NMP) used as a dispersion medium. 5g of acrylic acid, 1g of ethylene glycol dimethacrylate and 0.5g of 1,1'-azobis(cyclohexanecarbonitrile) were added to the prepared silicon slurry, and then stirred at 70°C for 12 hours. This prepares a silicon-polymer matrix slurry.

[0103] Here, D50 was 120 nm as a result obtained by measuring silicon distribution properties on the silicon-polymer matrix slurry by a dynamic light scattering method (measuring instrument: ELS-Z2, manufactured by Otsuka Electronics).

[0104] The prepared silicon-polymer matrix slurry was additionally heat-treated in an electric furnace at a temperature of 400° C. for 1 hour to prepare a silicon-polymer carbonized matrix, which was ground by using a planetary ball mill at 250 rpm Pulverized for 30 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com