Coating composition and coated film obtained therewith, multilayer structure and multilayer structure manufacturing method

一种涂布组合物、多层结构体的技术,应用在对表面涂布液体的装置、涂层、化学仪器和方法等方向,能够解决耐热性评价局限等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0153] Hereinafter, although an Example is given and this invention is demonstrated more concretely, this invention is not limited to the following Example unless the summary is exceeded.

[0154] In addition, unless otherwise specified, "part" in an Example means a basis of weight.

Embodiment 1

[0167]

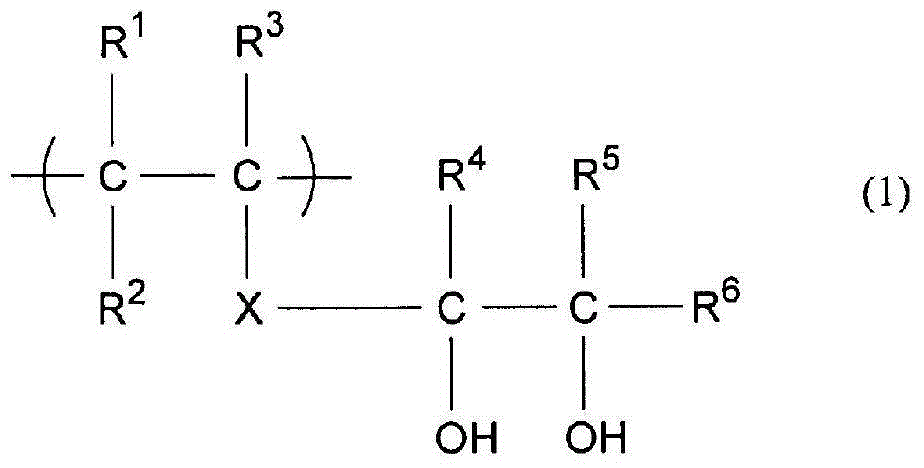

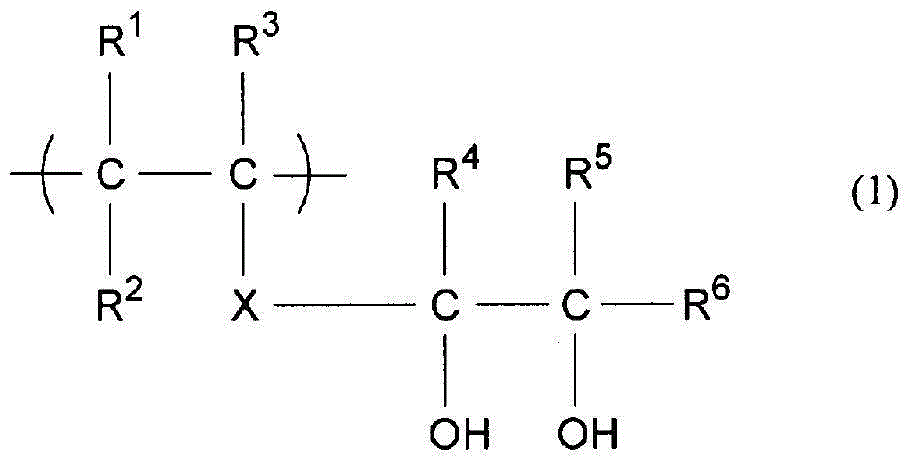

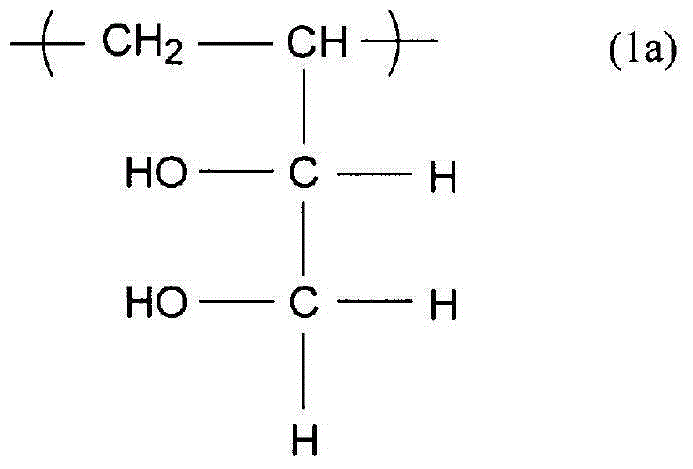

[0168] As the dispersion medium of the emulsion, water is used; as the dispersant, polyvinyl alcohol resin (saponification degree: 98.5 mol %; average polymerization degree 300; 1,2-diol structural unit content: 8 mol %); for the acrylic monomer forming the acrylic resin as the dispersoid, use butyl acrylate / methyl methacrylate=55 / 45 (weight ratio) of mixed monomers.

[0169] The polyvinyl alcohol resin (saponification degree: 98.5 mol %; average degree of polymerization 300; 1,2-diol structural unit content: 8 46.2 parts of mole %) were dissolved in 715 parts of water to prepare an aqueous solution. In addition, 700 parts of mixed monomers of butyl acrylate / methyl methacrylate=55 / 45 (weight ratio) as an acrylic monomer were prepared.

[0170] The above-mentioned aqueous solution was charged into a stainless steel reaction container equipped with a stirrer and a reflux condenser, and the temperature of the reaction container was kept at 80°C.

[0171] 70 parts of...

Embodiment 2

[0184] A coating composition and a film were prepared in the same manner as in Example 1, except that the compounding amount of the alumina fibrous fine particle sol in Example 1 was 15.08 parts by weight (corresponding to 0.71 parts by weight of the alumina component). , perform the same evaluation.

[0185] The total solid content in the coating composition was 39.2% by weight. In this coating composition, the solid content of the PVA-based resin in the coating composition was 5.4% by weight. In this coating composition, the compounding quantity of the metal oxide fibrous fine particle was 1.6 weight part with respect to 100 weight part of resin solid content in a coating composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com