Smoke dust detection and purifying method and device applied in 3D printing sealed cabin

A technology of 3D printing and purification equipment, which is applied in the field of laser selective melting metal 3D printing processing molding equipment, which can solve the problems of dust falling off, polluting powder, and affecting processing quality, so as to achieve the effect of ensuring high quality and high quantity and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

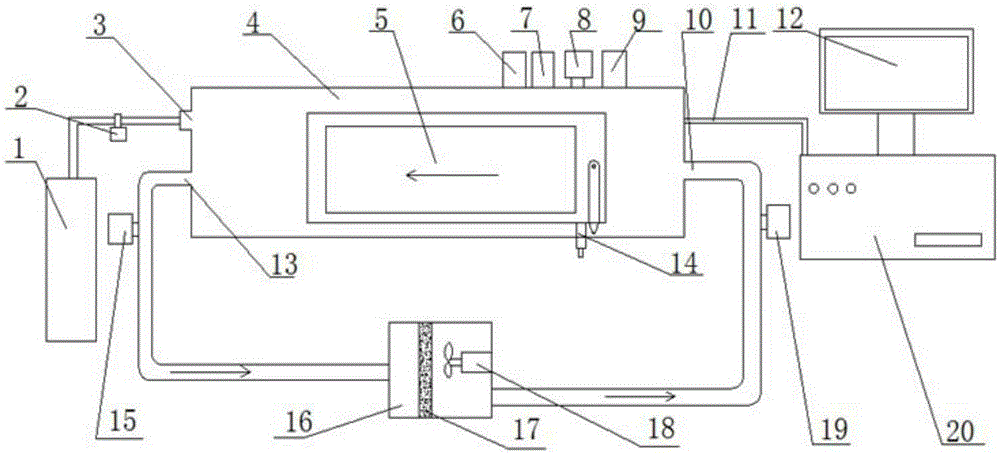

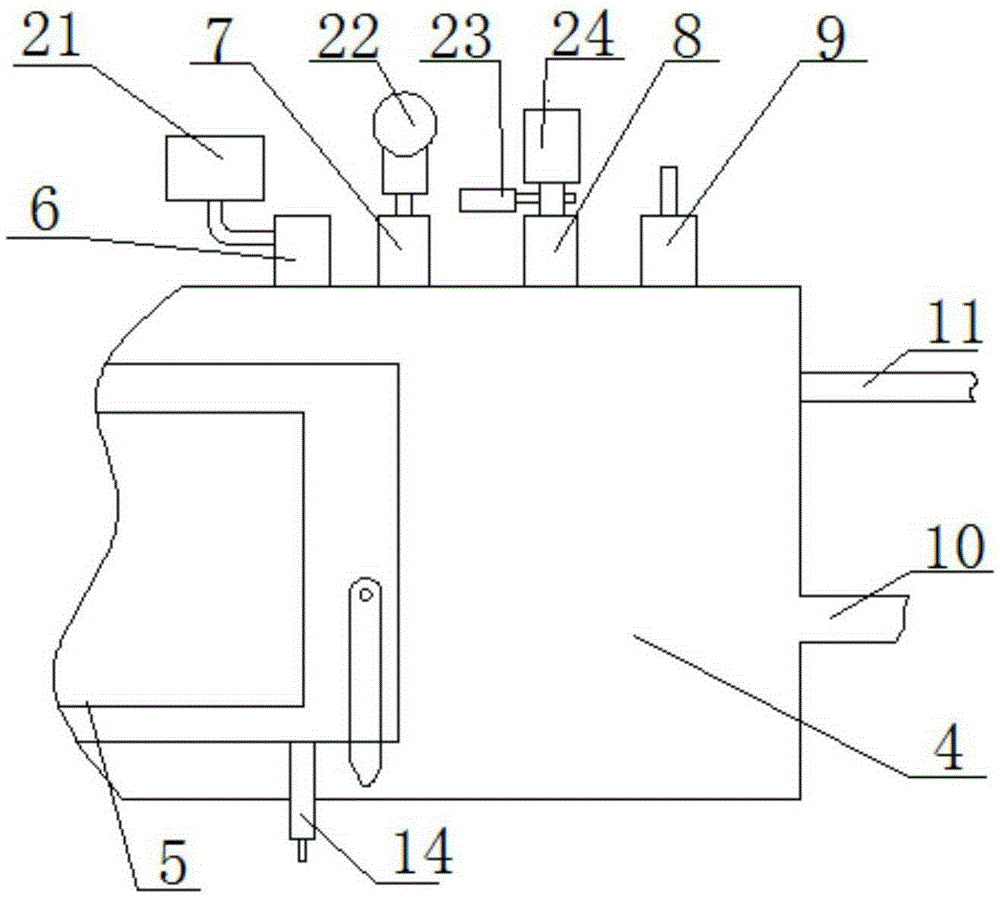

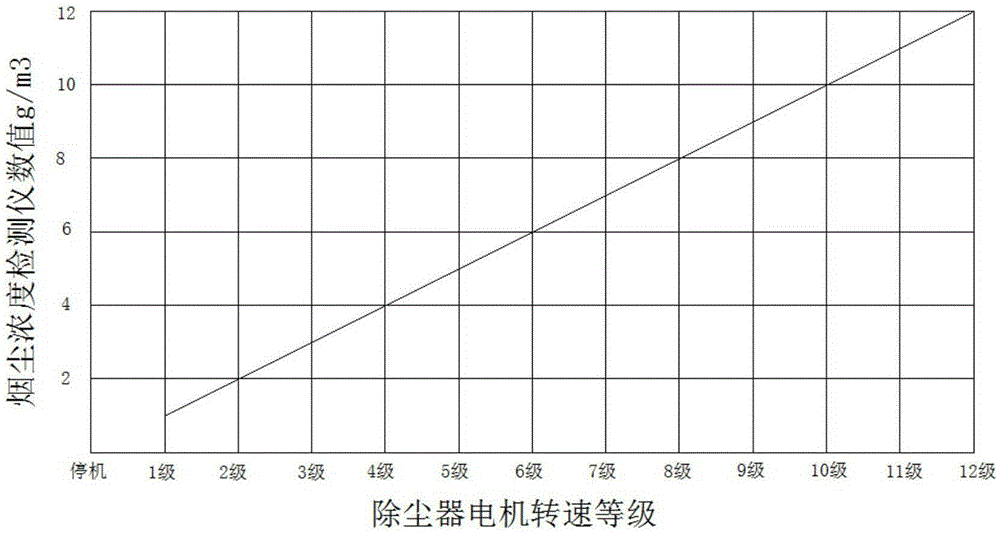

[0032] as the picture shows. The invention is a smoke detection and purification equipment applied in a 3D printing sealed cabin, including a sealed cabin 4, a gas supply device for the sealed cabin, a gas circulation purification system for circulating and purifying the gas in the sealed cabin 4, and a gas circulation purification system for detecting the sealed cabin A smoke concentration detection device for the smoke concentration in 4, an oxygen detection device for detecting the oxygen content in the sealed cabin 4, and a control device 20;

[0033] The control device 20 is respectively connected to the gas circulation purification system, the smoke concentration detection device, and the oxygen detection device through the cable 11;

[0034] The gas circulation purification system includes a smoke dust purifier 16, the air intake pipeline of the smoke dust purifier 16 is connected to the gas circulation inlet 13 of the sealed cabin 4, and the gas outlet pipeline of the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com