Method for removing organic matter from ketazine process hydrazine hydrate

A technology of ketazine method and hydrazine hydrate, which is applied in the direction of nitrogen and non-metallic compounds, hydrazine, etc., can solve the problem that organic impurities cannot be removed, and achieve the effect of reducing operating costs, low energy consumption, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

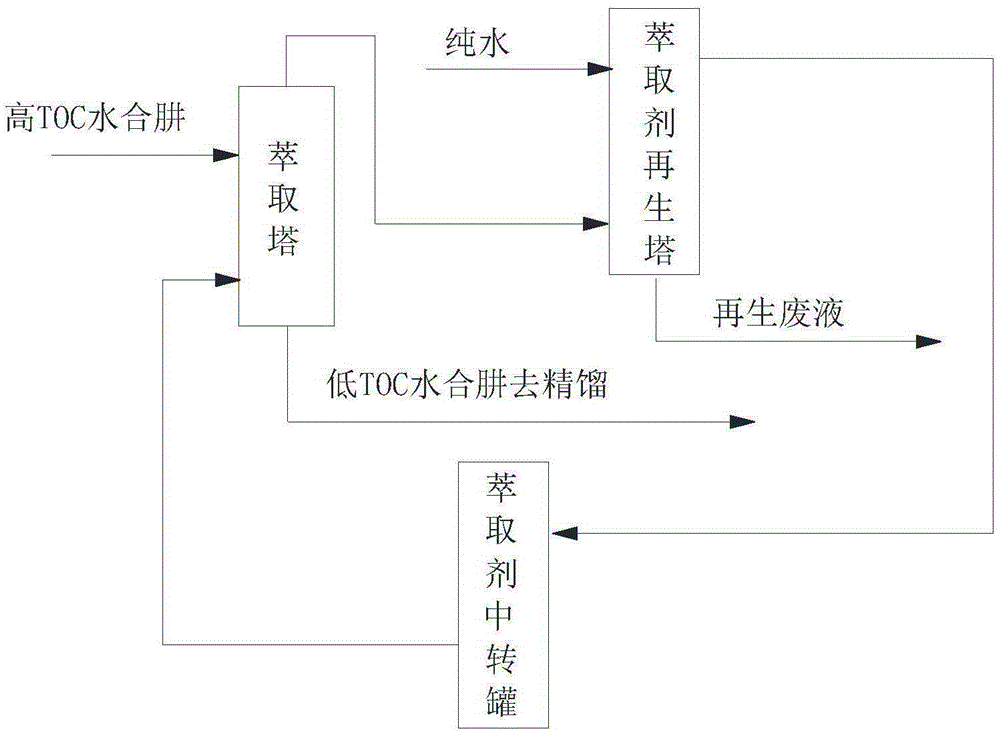

Method used

Image

Examples

Embodiment 1

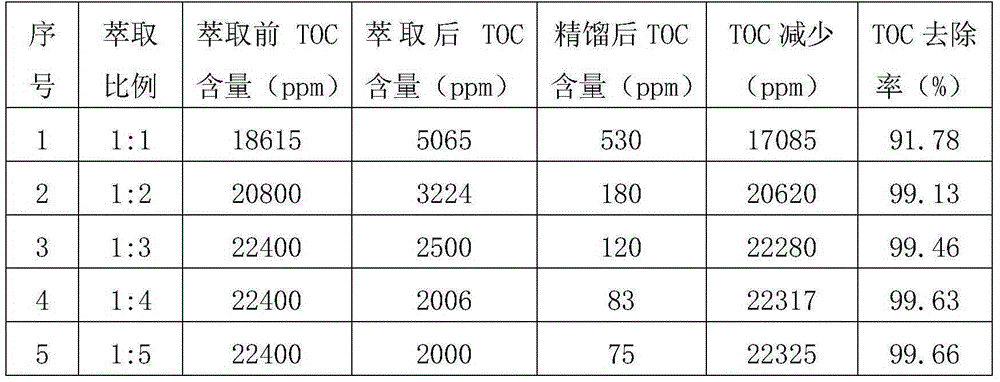

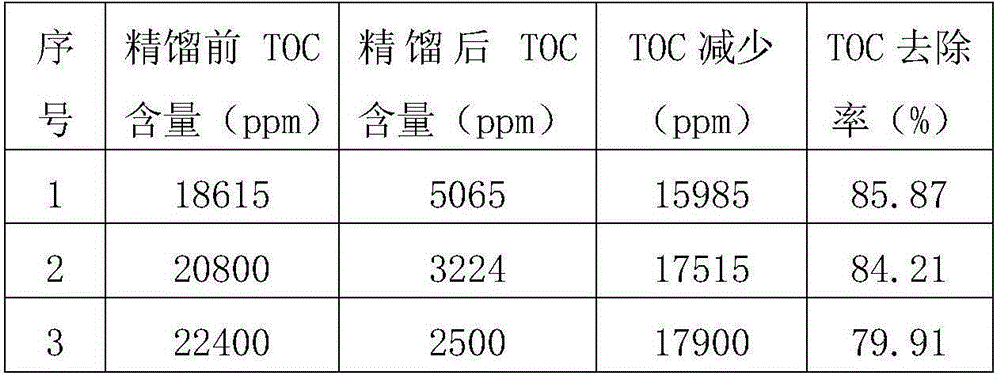

[0032] Add 100L of hydrazine hydrate with a hydrazine content of 60% (weight) and 200L of extractant toluene into the extraction tower, stir at 35°C for 3 minutes and then let stand for 10 minutes, phase separation occurs, and the organic layer is removed to obtain hydrated Hydrazine solution, and then pass the hydrazine hydrate solution with lower TOC content into the subsequent rectification system for rectification and impurity removal, and the TOC removal rate reaches 99.13%. The extraction agent toluene containing a large amount of organic impurities in the extraction tower is sent to the extraction agent regeneration tower, and pure water is used for back extraction and purification, and then stored in the extraction agent transfer tank for use in the extraction tower extraction. The whole extraction process is carried out continuously in the extraction tower without interruption.

Embodiment 2

[0034] Add 100L of hydrazine hydrate with a hydrazine content of 60% (weight) and 400L of extractant toluene to the extraction tower, stir at 40°C for 3 minutes and then let stand for 12 minutes, phase separation occurs, and the organic layer is removed to obtain hydrated Hydrazine solution, and then the hydrazine hydrate solution with lower TOC content was rectified to remove impurities. TOC analysis showed that the TOC removal rate reached 99.63%, and the TOC content dropped to 83ppm.

Embodiment 3

[0036] Add 100L of hydrazine hydrate with a high TOC content of 60% (weight) of hydrazine to be removed and 500L of extractant aniline into the extraction tower, stir at 45°C for 3 minutes and then let stand for 15 minutes, phase separation occurs, and organic layer to obtain a hydrazine hydrate solution, and then rectify the hydrazine hydrate solution with a low TOC content to remove impurities. The TOC analysis shows that the TOC removal rate reaches 99.66%, and the TOC content drops to 75ppm. The extraction agent aniline containing a large amount of organic impurities in the extraction tower is sent to the extraction agent regeneration tower, and pure water is used for back extraction and purification, and then stored in the extraction agent transfer tank for use in extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com