Cross-linked copolymer resin and preparation method thereof

A technology of cross-linked copolymer resin and linked copolymer resin, which is applied in the field of multi-component copolymer cross-linked resin and its preparation, can solve the problems of severe reaction, etc., and achieve the effect of simple production process and easy control of reaction temperature

- Summary

- Abstract

- Description

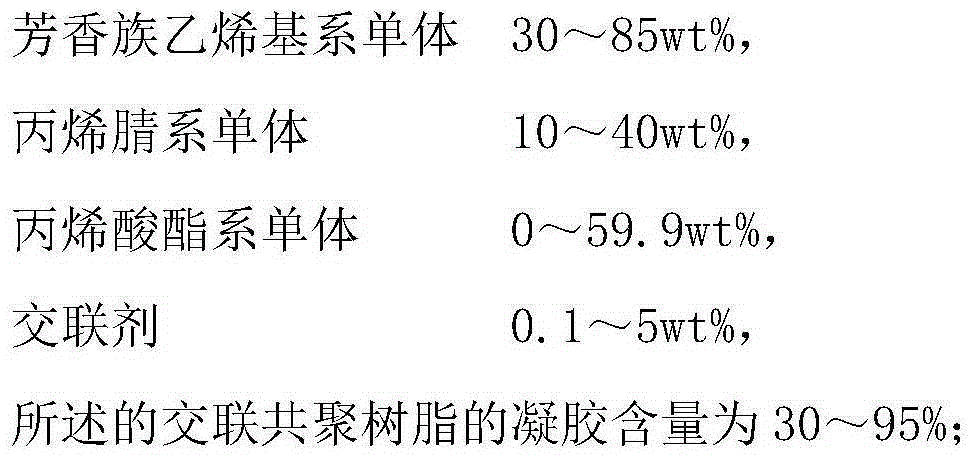

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

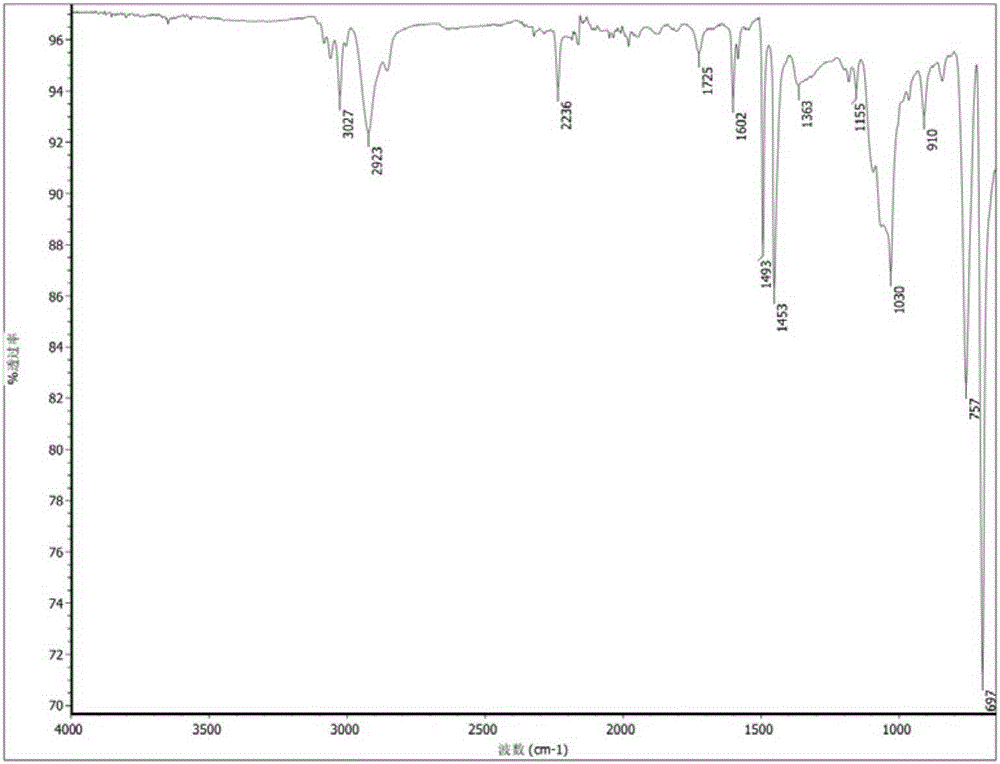

Embodiment 1

[0052] Styrene accounting for 65% of the total amount of monomers, acrylonitrile accounting for 20% of the total amount of monomers, ethylene glycol diacrylate accounting for 0.85% of the total amount of monomers, and all molecular weight regulators accounting for 1% of the total amount of monomers Dialkyl mercaptan, all oil-soluble initiator azobisisobutyronitrile accounting for 0.25% of the total amount of monomers, all dispersant active calcium phosphate accounting for 1.5% of the total amount of monomers, all The auxiliary dispersant sodium dodecylbenzene sulfonate and the deionized water with a weight ratio of 1.5:1 to the total monomer are mixed in the reaction kettle, and the temperature is raised to 65-80°C under stirring, and the reaction is carried out for 0.5 hours, and then the monomer After mixing styrene with 10% of total volume, acrylonitrile with 5% of total monomer and ethylene glycol diacrylate with 0.15% of total monomer, they were continuously added dropwise...

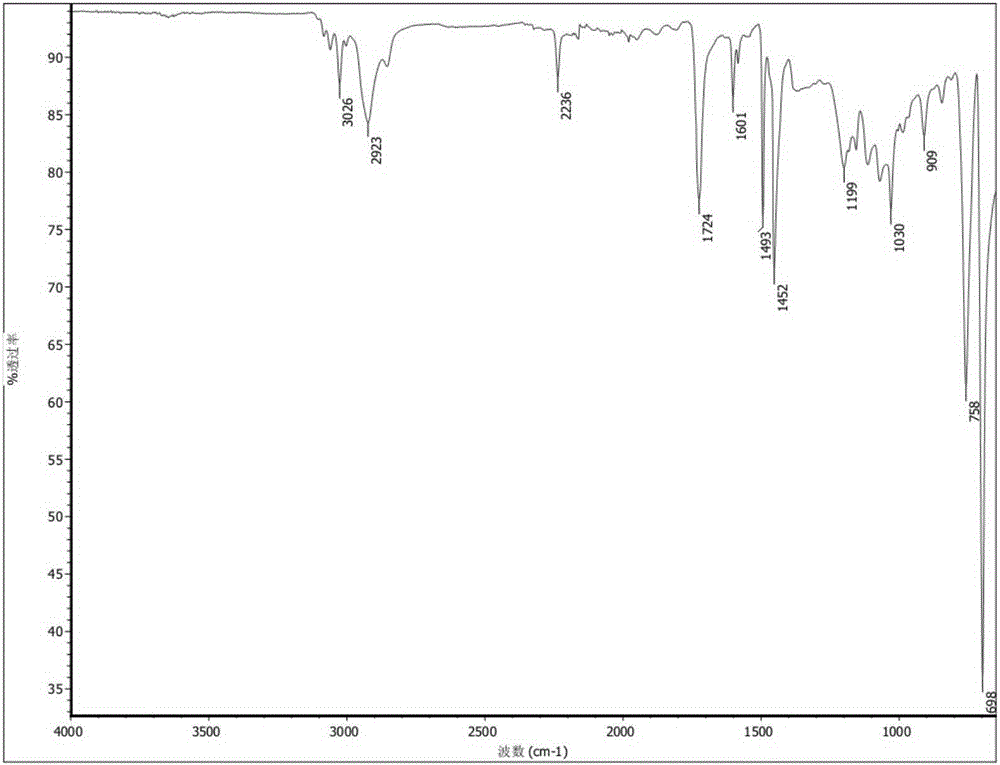

Embodiment 2

[0059] Styrene accounting for 72% of the total amount of monomers, acrylonitrile accounting for 13% of the total amount of monomers, ethylene glycol diacrylate accounting for 0.1% of the total amount of monomers, and all molecular weight modifiers accounting for 0.1% of the total amount of monomers Dialkyl mercaptan, all oil-soluble initiator azobisisobutyronitrile accounting for 0.25% of the total amount of monomers, all dispersant active calcium phosphate accounting for 1.5% of the total amount of monomers, all The auxiliary dispersant sodium dodecylbenzene sulfonate and the deionized water with a ratio of 1:1 to the total weight of the monomers are mixed in the reaction kettle, and the temperature is raised to 65-80°C under stirring, and the reaction is carried out for 0.5 hours, and then the monomers After mixing 13% styrene in total volume and 2% acrylonitrile in total monomer volume, they were continuously added dropwise into the reactor within 2 hours, continued to react...

Embodiment 3

[0064] Styrene accounting for 51% of the total amount of monomers, acrylonitrile accounting for 34% of the total amount of monomers, ethylene glycol diacrylate accounting for 4.25% of the total amount of monomers, and all molecular weight regulators accounting for 3% of the total amount of monomers Dialkyl mercaptan, all oil-soluble initiator azobisisobutyronitrile accounting for 0.25% of the total amount of monomers, all dispersant active calcium phosphate accounting for 1.5% of the total amount of monomers, all The auxiliary dispersant sodium dodecylbenzenesulfonate and the deionized water with the total weight ratio of the monomers are mixed in the reaction kettle, and the temperature is raised to 65-80°C under stirring, and the reaction is 0.5 hours, and then the monomer After mixing styrene with 9% of total volume, acrylonitrile with 6% of total monomer and ethylene glycol diacrylate with 0.75% of total monomer, they were continuously added dropwise to the reactor within 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com