Preparation method of self-cleaning formaldehyde removing wall cloth

A self-cleaning, wall covering technology, used in textiles and papermaking, fiber processing, plant fibers, etc., to avoid unevenness, grow evenly and stably, and distribute evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

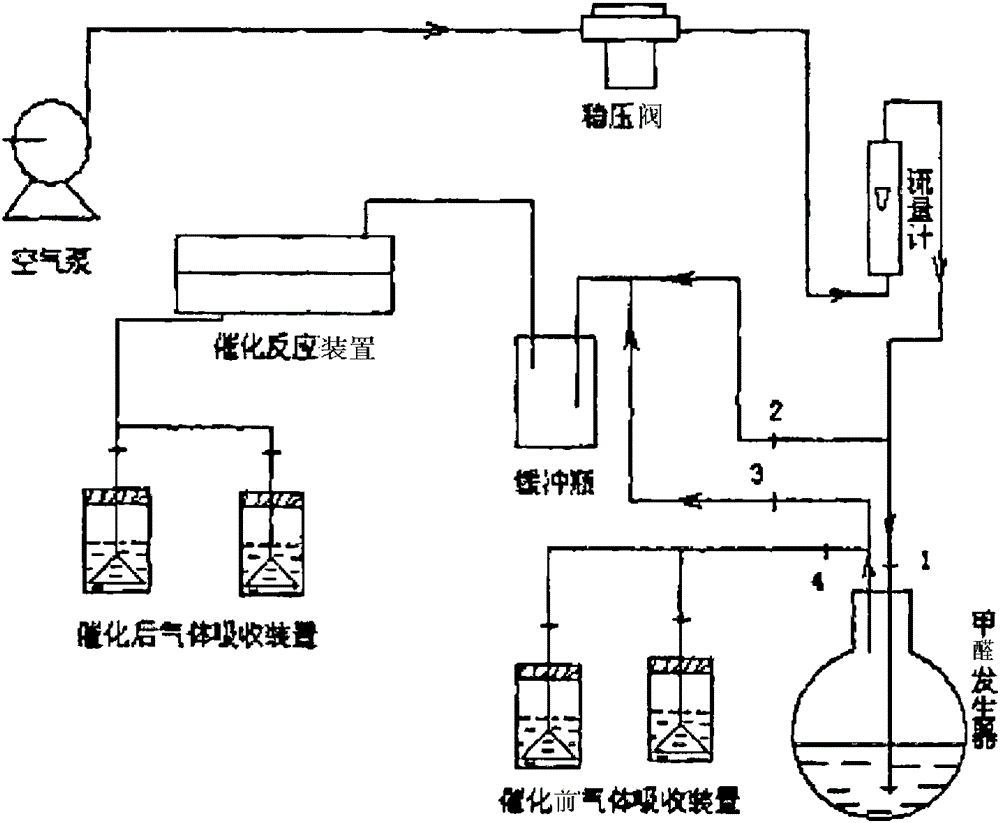

Method used

Image

Examples

Embodiment 1

[0059] A preparation method for self-cleaning formaldehyde-removing wall cloth, comprising the following steps:

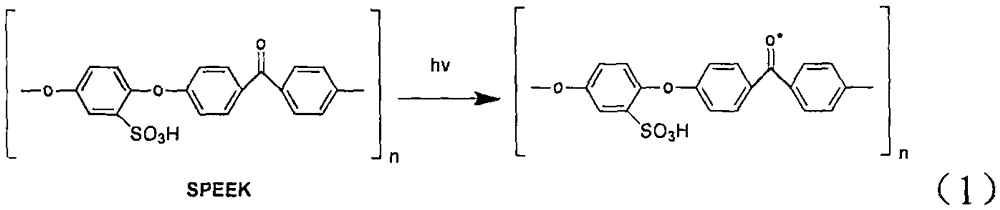

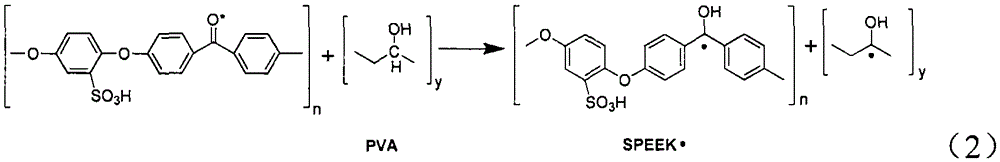

[0060] (1) Preparation of photo-induced free radical polymer composite finishing solution:

[0061] Every 1 kilogram of photo-induced free radical macromolecule composite finishing liquid is made up of the following components: the degree of etherification is 9g of sulfonated polyetheretherketone of 70%; hydrogen atom donor polymer 7g; crosslinking agent 1.7wt% (crosslinking agent Weight accounts for the percentage of sulfonated polyether ether ketone and hydrogen atom donor polymer total weight); An appropriate amount of acetic acid adjusts the pH value of the finishing solution to 5; the balance is deionized water; the hydrogen atom donor polymer is polyvinyl alcohol, The joint agent is glutaraldehyde;

[0062] Preparation steps: Put sulfonated polyether ether ketone and 400mL deionized water into a 3-liter stirring container, heat to 50°C under stirring, and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com