A kind of manufacturing method of fingerprint collection optical fiber panel

An optical fiber panel and a technology for manufacturing methods, which are applied in the direction of optical fiber bundles, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of unfavorable promotion and use of fingerprint recognition systems, expensive materials, and complicated manufacturing, so as to meet market competition needs and reduce material costs. The effect of low and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A kind of manufacturing method of fingerprint collection optical fiber panel

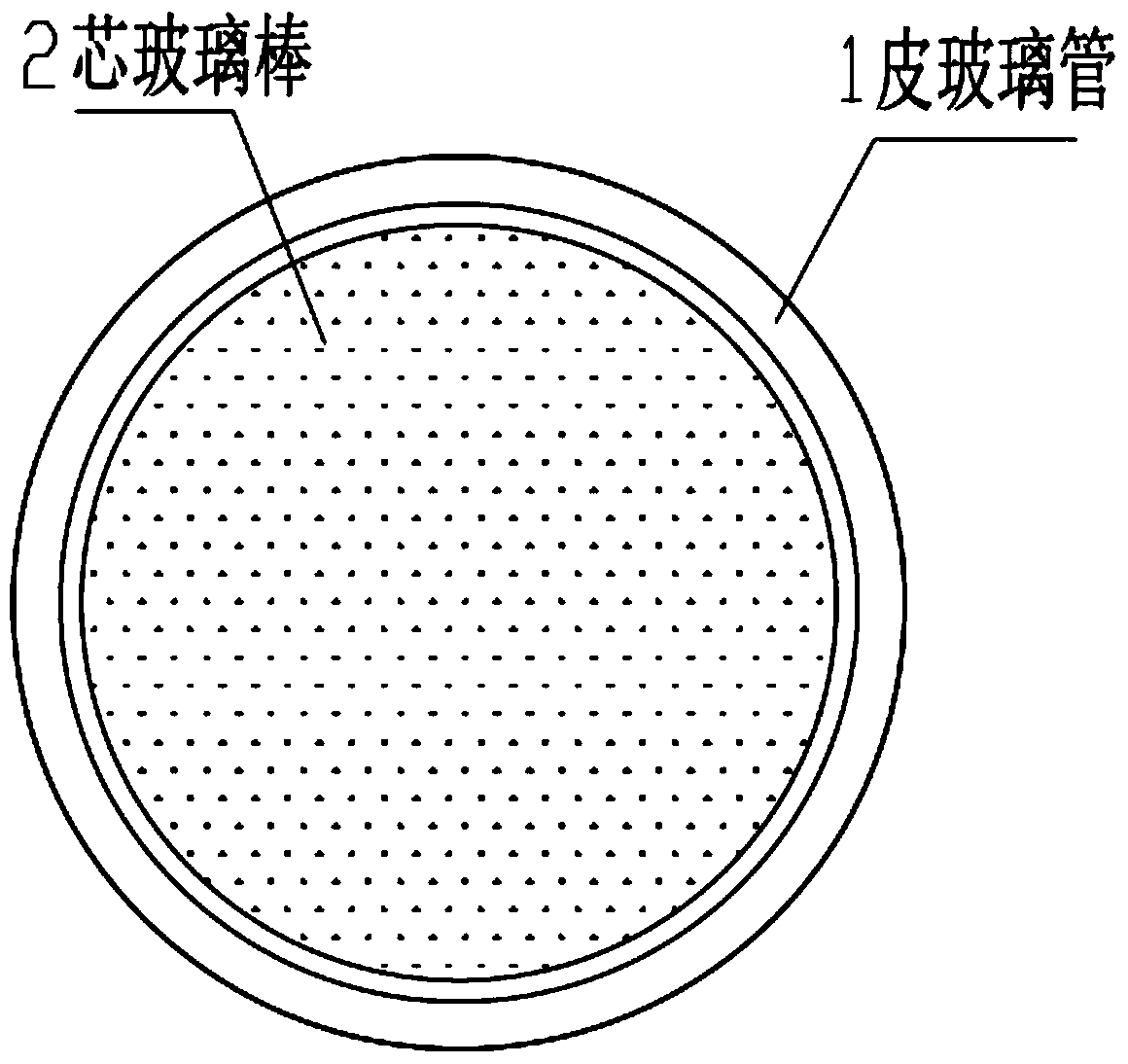

[0065] 1) Drawing of single optical fiber

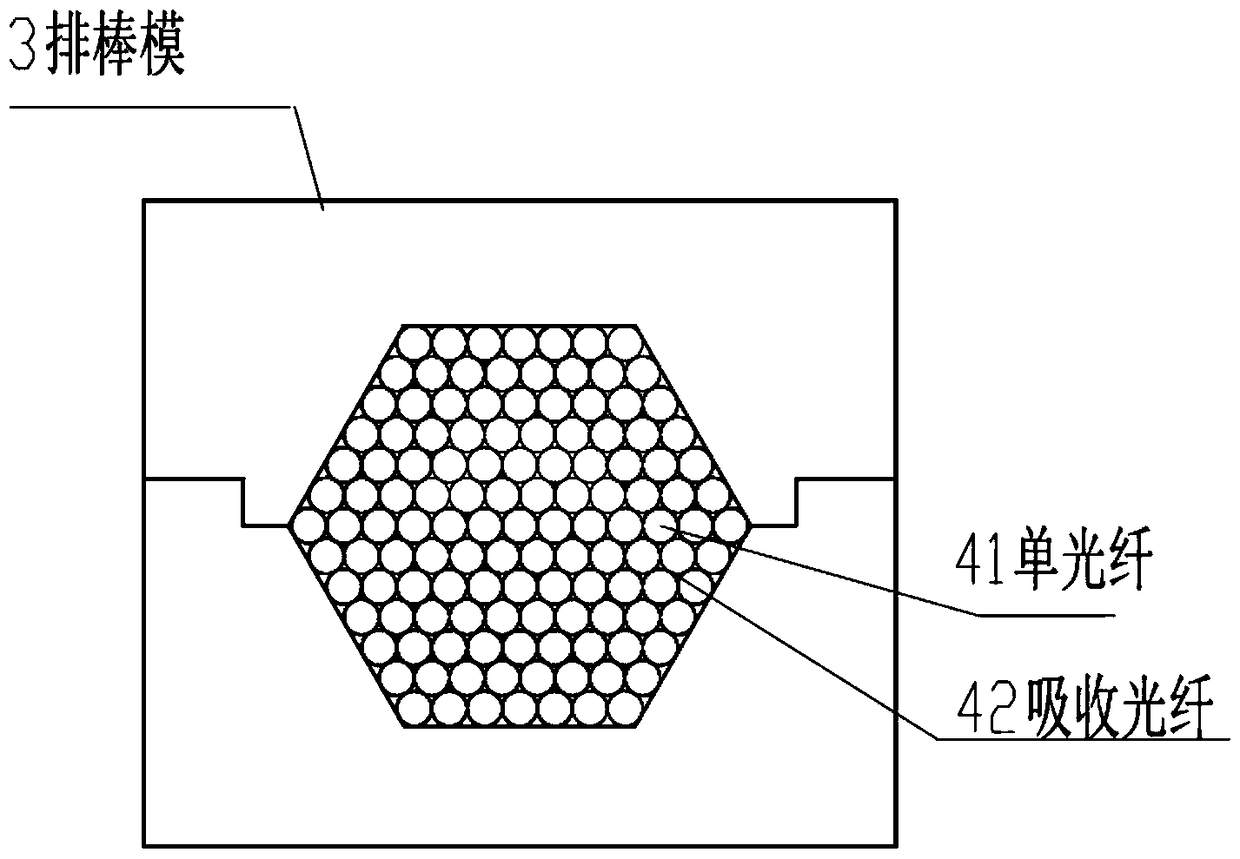

[0066] Such as figure 1 As shown, the core glass rod 1 is inserted into the skin glass tube 2, and the two are combined concentrically, and then hung on the wire drawing equipment, the skin glass tube is pumped, and the temperature of the wire drawing furnace is started to rise to the softening temperature of the glass 770~800 ℃ (the temperature can be adjusted appropriately according to the softening condition of the fiber in the drawing furnace and the actual drawing process), the glass softens and sags, and then is pulled and stretched by the drawing wheel, and the skin glass tube and the core glass rod will be bonded together, and passed through the cutting of the drawing machine When the fiber device is used, the optical fiber is cut into equal-length single fibers to form corresponding single fiber filaments 41 (such as figure 2 shown), the...

Embodiment 2

[0083] Embodiment 2: A method of making an optical fiber panel

[0084] 1) Drawing of single optical fiber

[0085] A core glass rod is inserted into the skin glass tube for concentric combination, and the rod-tube assembly is drawn into a single optical fiber; the drawing temperature is 770-800°C; the core glass rod is a glass rod with a refractive index of 1.65-1.80; the said The leather glass tube is a glass tube with a refractive index of 1.45~1.60.

[0086] 2) Drawing of stray light absorbing filament

[0087] The stray light absorbing glass is drawn into the stray light absorbing filament, and the drawing temperature is 750~780°C; the size of the stray light absorbing filament is determined according to the size of the single fiber, and is used to insert into the gap between the single fiber and the single fiber;

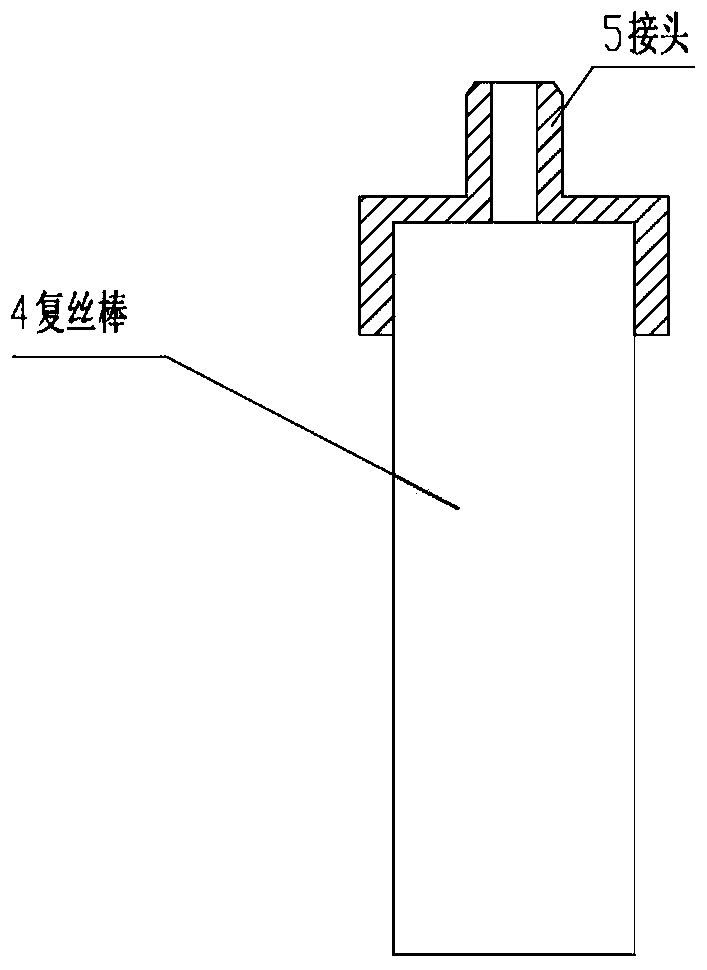

[0088] 3) Drawing of composite optical fiber

[0089] Arrange the drawn single optical fibers tightly into the regular hexagonal cavity of the row of rods,...

Embodiment 3

[0096] Embodiment 3: A method of making an optical fiber panel

[0097] 1) Drawing of single optical fiber

[0098] A core glass rod is inserted into the skin glass tube for concentric combination, and the rod-tube assembly is drawn into a single optical fiber; the drawing temperature is 770-800°C; the core glass rod is a glass rod with a refractive index of 1.65-1.80; the said The leather glass tube is a glass tube with a refractive index of 1.45~1.60.

[0099] 2) Drawing of stray light absorbing filament

[0100] The stray light absorbing glass is drawn into the stray light absorbing filament, and the drawing temperature is 750~780°C; the size of the stray light absorbing filament is determined according to the size of the single fiber, and is used to insert into the gap between the single fiber and the single fiber;

[0101] 3) Drawing of composite optical fiber

[0102] Arrange the drawn single optical fibers tightly into the regular hexagonal cavity of the row of rods,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com