Flat high-voltage transformer and manufacturing method thereof

A technology for high-voltage transformers and flat plates, which is applied in the manufacture of transformers, fixed transformers, inductors/transformers/magnets, etc. It can solve the problems of printed circuit board chemical corrosion process, poor anti-seismic performance, high production cost, etc., and achieve easy assembly and environmental protection performance Good, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

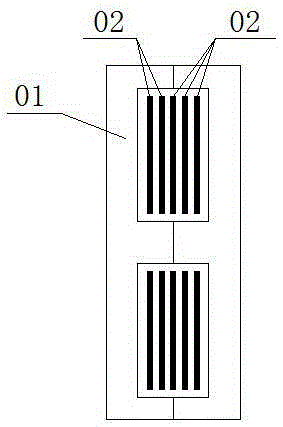

[0043] Such as Figure 1 to Figure 5 As shown, a flat high-voltage transformer includes a magnetic core 1 and a winding 2. The winding 2 includes at least two primary windings 21 and a plurality of secondary windings 22. The number of primary windings 21 and secondary windings 22 can be determined according to design requirements. . The primary winding 21 is made of electromagnetic wire, or when a large primary current is required, the primary winding 21 can be wound with copper tape or other materials, and the secondary winding 22 is made of electromagnetic wire, and the electromagnetic wire can be Wire covered wire, enameled wire, triple insulated wire, etc. The aforementioned background technology has been introduced. In the existing planar high-voltage transformer, the multilayer printed circuit board 02 is formed by stacking the primary winding and the secondary winding. In this embodiment, the primary winding 21 and the secondary winding 22 are opposite to each other. ...

Embodiment 2

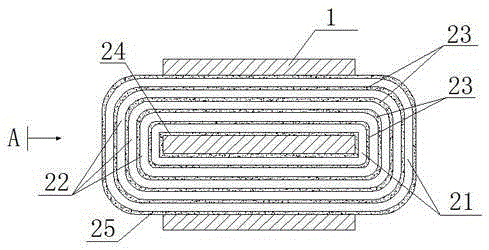

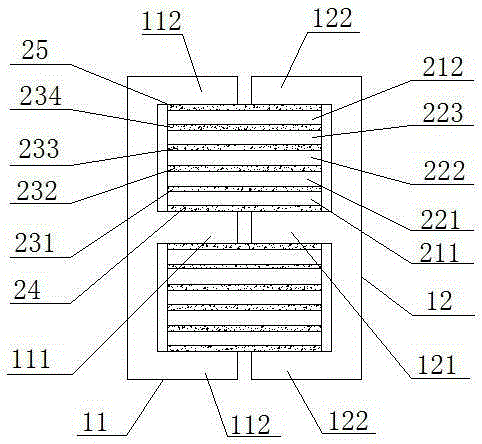

[0046] Such as Figure 2 to Figure 5 As shown, this embodiment is a further optimization of Embodiment 1, which is a three-output planar high-voltage transformer. In this embodiment, the winding 2 includes two primary windings 21 and three secondary windings 22, the inner side and the outer side of the winding 2 are primary windings 21, the two primary windings 21 are connected in parallel, and the three secondary windings 22 are located at two Intergroup insulation 23 is provided between each primary winding 21, between adjacent primary windings 21 and secondary windings 22, and between adjacent secondary windings 22. The magnetic core 1 includes a first magnetic core 11 and a second magnetic core 12, the first magnetic core 11 and the second magnetic core 12 are both "E" type magnetic cores, and the center of the first magnetic core 11 is provided with a A column 111, a first side plate 112 is provided on the opposite sides of the first magnetic core 11, a second core colum...

Embodiment 3

[0049] Such as Figure 4 to Figure 6 As shown, the difference between this embodiment and embodiment 2 is that the first magnetic core 11 selects an "E" type magnetic core, the second magnetic core 12 selects an "I" type magnetic core, and the first magnetic core 11 and the second The magnetic cores 12 are combined into a "day" shape, and the winding 2 is located in the "E"-shaped winding space of the first magnetic core 11 . In this embodiment, the cross-section of the planar high-voltage transformer includes in order from inside to outside: first magnetic core center column 111, bottom layer insulation 24, primary winding 21, intergroup insulation 23, secondary winding 22, intergroup insulation 23, secondary The primary winding 22 , the intergroup insulation 23 , the secondary winding 22 , the intergroup insulation 23 , the primary winding 21 , the outer layer insulation 25 , and the first side plate 112 . Compared with Embodiment 2, the second magnetic core 12 in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com