Rubber-reinforced thermoplastic resin composition and resin molded article

A thermoplastic resin and composition technology, which is applied in the field of rubber-reinforced thermoplastic resin compositions and their molded products, can solve the problems of non-optimization, reduce manufacturing costs, etc., and achieve the effects of short cooling and curing time and excellent mold release properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

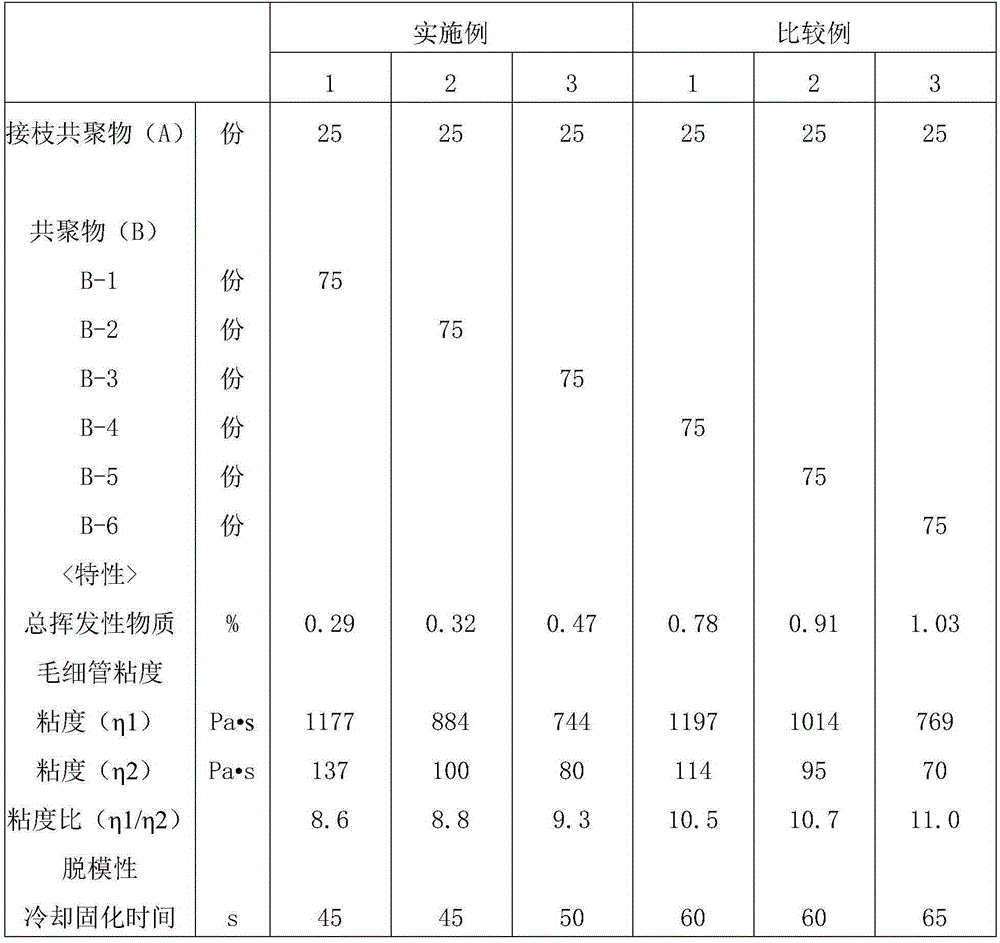

[0047] Hereinafter, the present invention will be specifically explained by showing examples, but the present invention is not limited by them. In addition, "parts" and "%" shown in the examples are based on mass.

[0048]

[0049] To the graft copolymer (A) and the copolymer (B) of the composition ratio shown in Table 1, 1.0 part of Sumiplast BlackHB (manufactured by Sumitomo Chemical Co., Ltd.) was mixed as a coloring agent. Using a 50 mm single-screw extruder (manufactured by Oenu Machinery) with vent holes, melt-mixing was performed at a barrel temperature of 210°C, and pellets dyed black were obtained by granulation. In addition, each component shown in Table 1 is as follows.

[0050] Manufacturing of rubber-like polymer (a)

[0051] Rubber-like polymer (a-1): Add 93 parts of 1,3-butadiene, 7 parts of styrene, 0.5 parts of n-dodecyl mercaptan, 0.24 parts of potassium persulfate, and 1.5 parts of rosin in a pressure vessel After sodium, 0.1 part of sodium hydroxide and 150 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average particle size | aaaaa | aaaaa |

| Weight average particle size | aaaaa | aaaaa |

| Reduced viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com