Liquid-chlorine production system

A production system and liquid chlorine technology, applied in the system field, can solve problems such as hidden safety hazards, low production efficiency, chlorine gas leakage, etc., and achieve the effects of improving production efficiency, solving low production efficiency, and avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

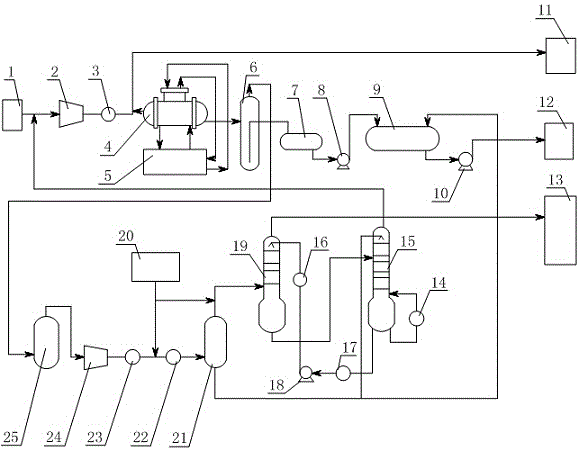

[0014] Such as figure 1 As shown, the liquid chlorine production system includes a chlorine gas generating device 1, and the chlorine gas generating device 1 is connected with a chlorine compressor-2, and the chlorine compressor-2 is connected with a cooling device-3, and the cooling device-3 is connected with a liquefier 4 and Finished product chlorine gas collecting device 11, liquefier 4 is connected with freezer-5 and gas-liquid separator 6, and gas-liquid separator 6 is connected with liquid chlorine collecting device 12 and buffer 25, between liquid chlorine collecting device 12 and gas-liquid separator 6 Liquid chlorine tank one 7 and liquid chlorine tank two 9 are arranged, liquid chlorine tank one 7 is connected with gas-liquid separator 6, and extraction pump one 8 is arranged between liquid chlorine tank one 7 and liquid chlorine tank two 9, and extraction pump one 8 is connected with liquid chlorine tank 1 7 and liquid chlorine tank 2 9 at the same time, liquid chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com