A kind of modified rubber material for automobile rubber hose and preparation method thereof

A technology of modified rubber and automobile rubber hose, which is applied in the field of rubber materials, can solve the problems of restricting the use of industrial products, the effect is not ideal, and it is difficult to meet the performance requirements, and achieves low cost, improved high temperature resistance and oil resistance, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

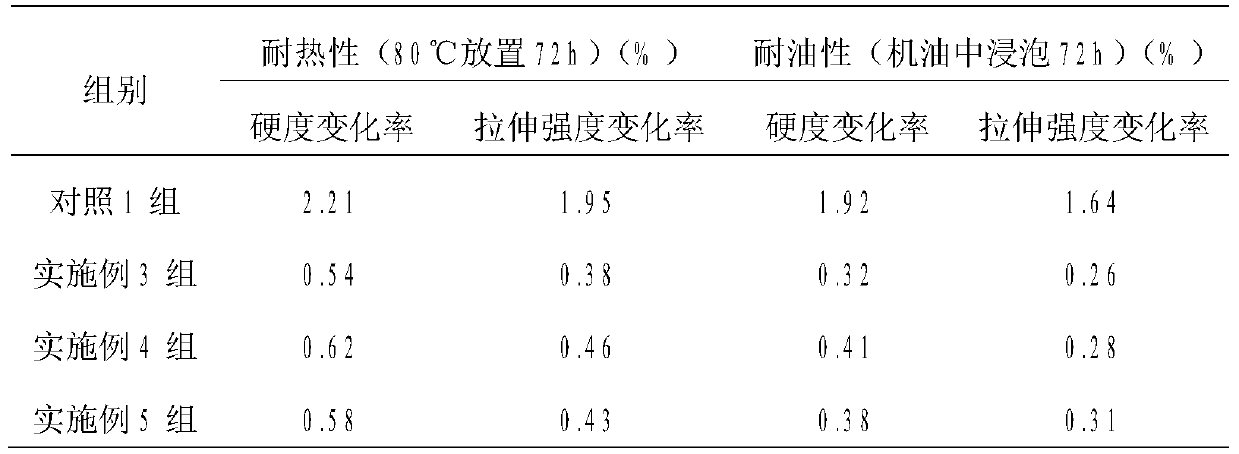

Examples

Embodiment 1

[0020] Party:

[0021] EPDM rubber 40 parts, maleic anhydride 10 parts, chlorinated polyethylene rubber 40 parts, silane coupling agent 2 parts, perfluoroether rubber 20 parts, zinc oxide 1 part, stearic acid 2 parts, carbon black 15 parts 2 parts of sulfur, 0.2 parts of butylated hydroxytoluene, 0.3 parts of zinc methacrylate, and 30 parts of acetone.

[0022] Preparation:

[0023] (1) Take EPDM rubber and maleic anhydride, add them to half the amount of acetone, react at 30°C for 10 hours, raise the temperature to 50°C, and continue to react for 10 hours to obtain the initial reaction solution;

[0024] (2) Take chlorinated polyethylene rubber and perfluoroether rubber, add them to the remaining acetone, mix them with the above initial reaction solution, and then add silane coupling agent, zinc oxide, stearic acid, carbon black, butyl Hydroxymethanol and zinc methacrylate are fully mixed and smelted at 60°C to obtain masterbatch;

[0025] (3) Molding the above-mentioned m...

Embodiment 2

[0027] Party:

[0028] EPDM rubber 40 parts, maleic anhydride 20 parts, chlorinated polyethylene rubber 60 parts, titanate coupling agent 8 parts, perfluoroether rubber 40 parts, zinc oxide 9 parts, stearic acid 6 parts, carbon Black 35 parts, sulfur 6 parts, butylated hydroxytoluene 0.8 parts, zinc methacrylate 0.7 parts, acetone 40 parts.

[0029] Preparation:

[0030] (1) Take EPDM rubber and maleic anhydride, add them to half the amount of acetone, react at 40°C for 20 hours, heat up to 60°C, and continue to react for 20 hours to obtain the initial reaction solution;

[0031] (2) Take chlorinated polyethylene rubber and perfluoroether rubber, add them to the remaining acetone, mix them with the above-mentioned initial reaction solution, and then add titanate coupling agent, zinc oxide, stearic acid, carbon black, Butylated hydroxymethyl and zinc methacrylate are fully mixed and melted at 80°C to obtain masterbatch;

[0032] (3) Molding the above-mentioned masterbatch, a...

Embodiment 3

[0034] Party:

[0035] 40 parts of EPDM rubber, 15 parts of maleic anhydride, 50 parts of chlorinated polyethylene rubber, 5 parts of aluminate coupling agent, 30 parts of perfluoroether rubber, 5 parts of zinc oxide, 4 parts of stearic acid, carbon Black 25 parts, sulfur 4 parts, butylated hydroxytoluene 0.5 parts, zinc methacrylate 0.5 parts, acetone 35 parts.

[0036] Preparation:

[0037] (1) Take EPDM rubber and maleic anhydride, add them to half the amount of acetone, react at 35°C for 15 hours, raise the temperature to 55°C, and continue to react for 15 hours to obtain the initial reaction solution;

[0038] (2) Take chlorinated polyethylene rubber and perfluoroether rubber, add them to the remaining acetone, mix with the above-mentioned initial reaction liquid, then add aluminate coupling agent, zinc oxide, stearic acid, carbon black, Butylated hydroxymethyl and zinc methacrylate are fully mixed and melted at 70°C to obtain masterbatch;

[0039] (3) Molding the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com