A kind of processing method of hydroalcolysis-resistant PPE/glass fiber masterbatch

A technology of glass fiber masterbatch and processing method, which is applied in the processing field of hydroalcolysis-resistant PPE/glass fiber masterbatch, and can solve the problem of decreased ability to resist corrosion of freezing liquid, resistance to alcoholysis agents or alcoholysis-resistant agents, and joints Problems such as stress cracking are not allowed to achieve the effect of solving mechanical properties, high mechanical properties, and excellent alcoholysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

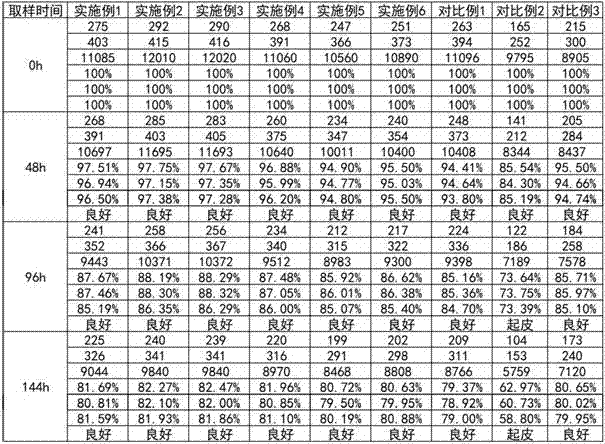

Examples

Embodiment 1

[0017] An alcoholysis-resistant nylon composite material for automobiles, consisting of the following components by weight percentage: 58.1% of nylon 6, 40% of PPE / glass fiber masterbatch, 0.5% of nucleating agent, 0.5% of antioxidant, and 0.6% of lubricant , heat stabilizer 0.3%.

[0018] The processing method of the alcoholysis-resistant nylon composite material for automobiles comprises the following steps:

[0019] (1) The processing method of PPE / glass fiber masterbatch, including the following steps:

[0020] a, first disperse graphene in water to form solution A, mix silane coupling agent with ethanol to form solution B, mix solution A and solution B at a mass ratio of 1:1 to prepare a mixed solution; wherein water in solution A and The mass ratio of graphene is 40:0.1, and the mass ratio of ethanol and silane coupling agent in solution B is 40:1; The silane coupling agent is 3-aminopropyltriethoxysilane;

[0021] b. Immerse the ordinary continuous glass fiber in the ...

Embodiment 2

[0029] An alcoholysis-resistant nylon composite material for automobiles, consisting of the following components by weight percentage: 58.5% of nylon 46, 40% of PPE / glass fiber masterbatch, 0.1% of nucleating agent, 0.4% of antioxidant, and 0.6% of lubricant , heat stabilizer 0.4%.

[0030] The processing method of the alcoholysis-resistant nylon composite material for automobiles comprises the following steps:

[0031] (1) The processing method of PPE / glass fiber masterbatch, including the following steps:

[0032] a, first disperse graphene in water to form solution A, mix silane coupling agent with ethanol to form solution B, mix solution A and solution B at a mass ratio of 1:1 to prepare a mixed solution; wherein water in solution A and The mass ratio of graphene is 45:1, and the mass ratio of ethanol and silane coupling agent in solution B is 35:0.8; The silane coupling agent is N-2-aminoethyl-3-aminopropyltrimethoxysilane;

[0033] b. Immerse the ordinary continuous gl...

Embodiment 3

[0041] Based on Example 2, the mass ratio of glass fiber to PPE resin is modified to 1:0.8, and the rest are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com