Preparation method for light oil

A light oil and heavy oil technology, applied in the field of oil refining and chemical industry, can solve the problem of low yield of light oil and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

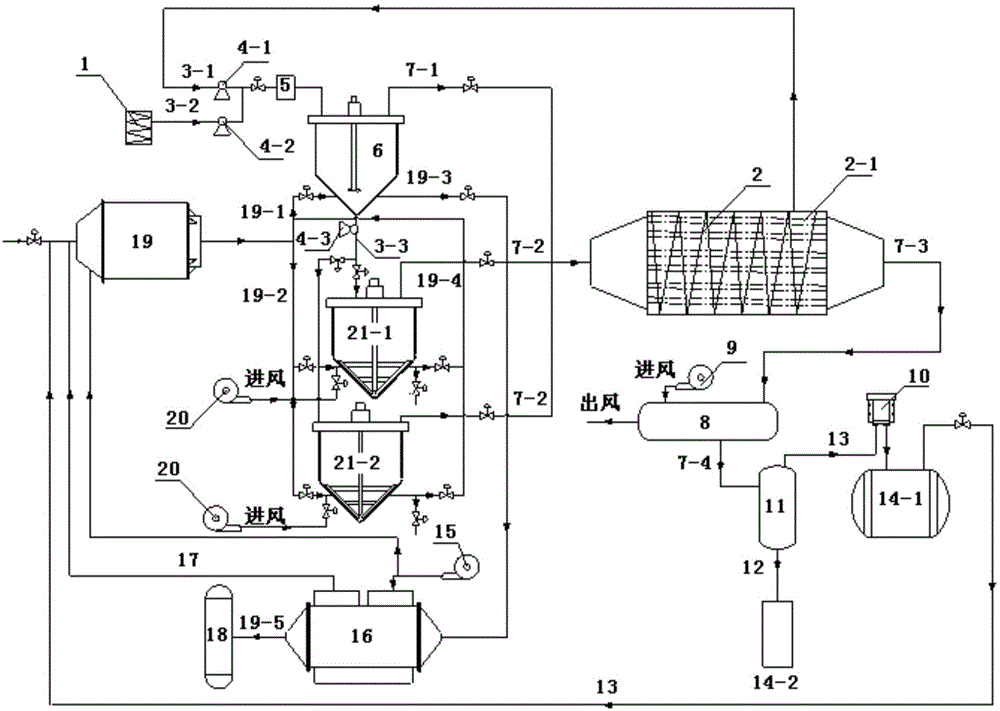

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of light oil, comprises the following steps:

[0029] 1), under the action of stirring, the heavy oil is visbroken to obtain an intermediate product;

[0030] 2) Under the action of stirring and catalyst, the intermediate product is subjected to catalytic cracking to obtain light oil.

[0031] The present invention combines visbreaking and catalytic cracking processes to prepare light oil. Both the visbreaking and catalytic cracking are carried out under the condition of stirring, and the reaction materials are dispersed by stirring to increase the liquid droplets of the reaction materials. The evaporation area increases, which in turn increases the surface curvature of the droplet, thereby increasing the vapor pressure of the droplet, which will increase the gasification of the reaction material during visbreaking and catalytic cracking, and reduce the amount of petroleum coke produced. , thereby improving the yield ...

Embodiment 1

[0057] The cobalt naphthenate of 25kg, the ethylene glycol monomethyl ether of 40kg, the acidified activated clay of 5kg, the glyceryl stearate of 10kg and the chlorinated paraffin 70 of 20kg are mixed homogeneously, obtain catalyst; Described acidified activated clay is obtained by mass It is obtained by mixing sulfuric acid with a concentration of 98% and clay at a mass ratio of 1:49.

Embodiment 2

[0059] The cobalt naphthenate of 20kg, the ethylene glycol monomethyl ether of 30kg, the acidified activated clay of 3kg, the glyceryl stearate of 20kg and the chlorinated paraffin 70 of 27kg are mixed homogeneously, obtain catalyst; Described acidified activated clay is obtained by mass It is obtained by mixing sulfuric acid with a concentration of 98% and clay at a mass ratio of 1:49.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com