Method for determining boiling loss in minced meat gelation process through low-field nuclear magnetic resonance

A low-field nuclear magnetic resonance, minced meat technology, applied in the direction of analysis using nuclear magnetic resonance, etc., can solve the problem of not being able to truly and effectively reveal the water retention properties of meat and meat products, unable to reflect the spatial distribution information of the water content of meat and meat products, destroying meat and meat products. Problems such as the structure and properties of meat products, to achieve the effect of solving high cooking loss rate, optimizing cooking temperature and time, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0032] Take minced meat products with a fat content of 20% as an example:

[0033] The traditional method for measuring cooking loss (moisture loss and fat loss): take about 30g of emulsified minced meat and place it in a centrifuge tube with a diameter of 50mm, and centrifuge at 560g on a high-speed centrifuge for 10min at 4°C. The fat layer and the water layer will be clearly separated, and then the water loss rate and fat loss rate in the emulsified minced meat are calculated respectively with the following formula:

[0034] Water loss (%) = mass of water layer (m l ) / total weight of emulsified meat (g)×100

[0035] Fat loss (%) = mass of fat layer (m 2 ) / total weight of emulsified meat (g)×100

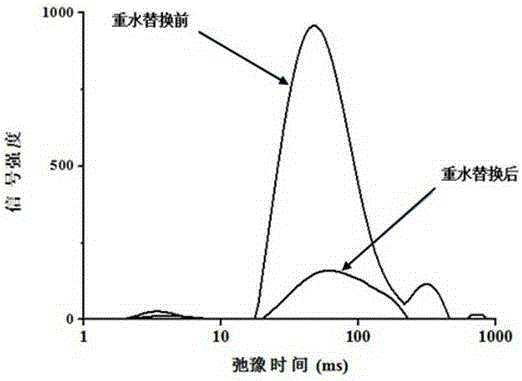

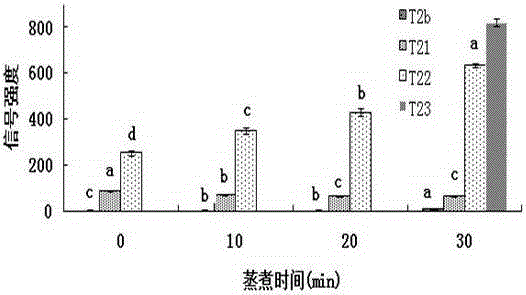

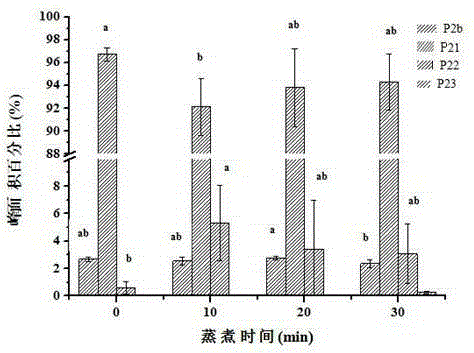

[0036] LF-NMR determination of cooking loss:

[0037] (1) Raw material sample preparation: surface tendons, fascia and fat were removed from pork hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com