Double-layer thin-wall trough steel bar all-welded annular vacuum container

A vacuum container, all-welding technology, applied in nuclear reactors, nuclear power generation, climate sustainability, etc., can solve the problems of complex container structure, difficult to process, increase the size and weight of the container, etc., and achieve simple wall structure, processing and welding. Easy, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

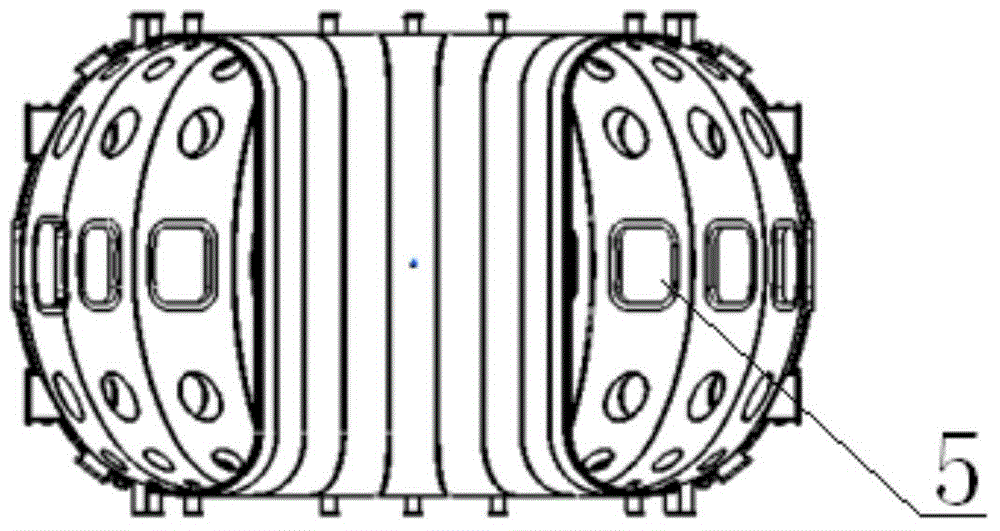

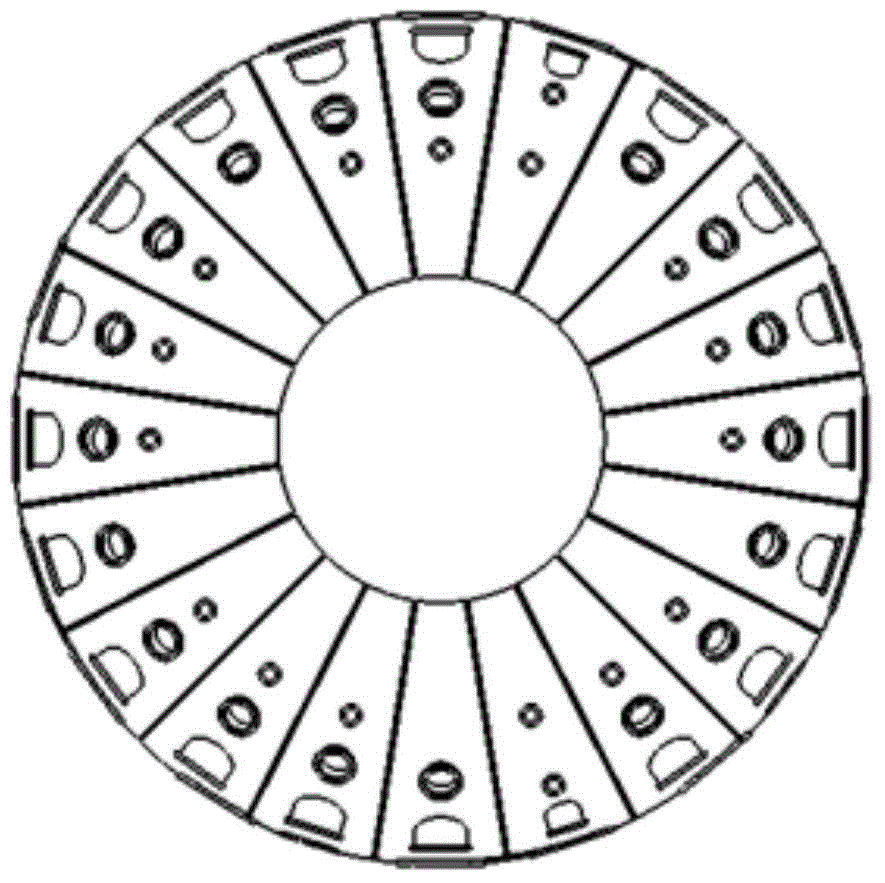

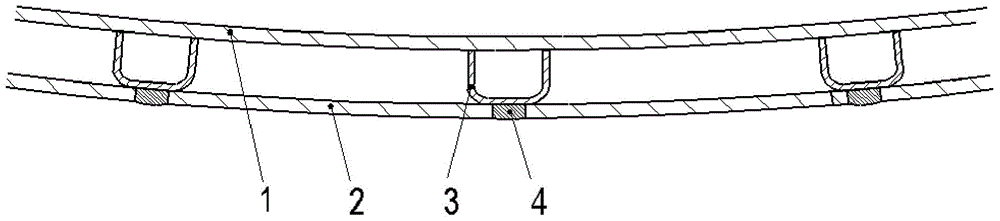

[0014] The technical route adopted by the present invention is as follows: a double-layer thin-walled annular vacuum container fully welded with groove steel bars, the container wall is mainly welded by inner wall, outer wall and groove steel bars; the wall material is nickel-based material-Inconel625.

[0015] According to the resistance calculation formula: ρ L S - - - ( 1 )

[0016] Where R is the resistance, ρ is the resistivity, L is the length, and S is the area.

[0017] From the formula (1), it can be known that the resistance is proportional to the resistivity of the material and inversely proportional to the area. The container adopts a thin-walled structure, which can reduce the cross-sectional area and increase the hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com