Anisotropic high-frequency microwave magnetic material and preparation method thereof

An anisotropic magnetic and magnetic material technology, applied in the field of easy-face anisotropic rare earth intermetallic compound high-frequency microwave magnetic materials and their preparation, to achieve excellent high-frequency microwave magnetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

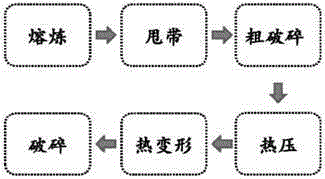

[0035] The invention provides a method for preparing an anisotropic rare earth intermetallic compound high-frequency microwave magnetic material, which comprises the following steps:

[0036] (1) Raw material preparation: mix rare earth metals, iron and boron-iron alloys by R x Fe 100-x-y B y (at%) ratio; wherein, 11.76<x≤15, 5.88≤y≤7.0, R is one of Sm, Er, Tm;

[0037] (2) Smelting: Under the protection of argon, melt the raw materials in the ratio of step (1) at 1480-1580°C to form ingots, and cool them; the ingots are smelted repeatedly for 3-5 times, so that the alloy composition is single and uniform; Alloys can be completely crystalline or partially amorphous, with a grain size of less than 500nm

[0038] (3) Swinging belt: The ingot smelted in step (2) is prepared into an amorphous or nanocrystalline quick-quenching belt by means of rapid quenching of the melt. The melting temperature is 1400°C-1500°C, and the water-cooled copper rod or The linear speed of the molyb...

Embodiment 1

[0046] Example 1-Sm 12 Fe 82.12 B 5.88

[0047] (1) Raw material preparation: according to the design composition Sm 12 Fe 82.12 B 5.88 Proportioning the rare earth metal Sm, iron and boron-iron alloy;

[0048] (2) Melting: under the protection of argon, melt the raw materials with good proportions at 1480°C to form ingots, and the ingots are smelted repeatedly for 3 times, so that the alloy composition is single and uniform; the grain size of the alloy is less than 500nm;

[0049] (3) Swinging belt: the ingot is prepared into an amorphous or nanocrystalline quick-quenching belt by means of rapid quenching of the melt, the melting temperature is 1400 ° C, and the linear velocity of the water-cooled copper rod rotating at high speed is 25 m / s;

[0050] (4) Coarse crushing: manually grind the quick-quenching belt to a particle size of less than 100 μm;

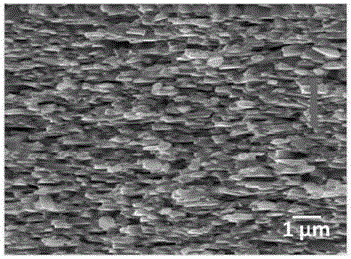

[0051] (5) Hot pressing: filled with argon gas after high vacuum, the vacuum degree is greater than 1×10 -2 Pa, the co...

Embodiment 2

[0054] Embodiment 2-Er 15 Fe 78 B 7.0

[0055] (1) Raw material preparation: according to the design composition Er 15 Fe 78 B 7.0 Rare earth metal Er, iron and boron ferroalloy are mixed;

[0056] (2) Melting: Under the protection of argon, melt the raw materials with a good ratio at 1580°C to form an ingot, and the ingot is smelted repeatedly for 5 times, so that the alloy composition is single and uniform; the alloy grain size is less than 500nm;

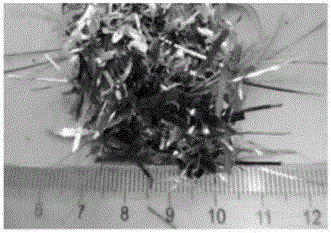

[0057] (3) Throwing strip: the ingot is prepared into an amorphous thin strip by the method of rapid quenching of the melt, the melting temperature is 1500 °C, the linear speed of the high-speed rotating water-cooled molybdenum roller is 45m / s, and the appearance of the rapid quenching strip is as follows Figure 4 shown;

[0058] (4) Coarse crushing: manually grind the quick-quenching belt to a particle size of less than 100 μm;

[0059] (5) Hot pressing: filled with argon gas after high vacuum, the vacuum degree is grea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com