A kind of industrial large-scale seed cultivation device and cultivation method of Penaeus japonicus

A cultivation method and large-scale technology, which is applied in the field of industrialized large-scale seed cultivation of Penaeus japonicus, can solve the problems of difficult management, instability, and small individuals in the early stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

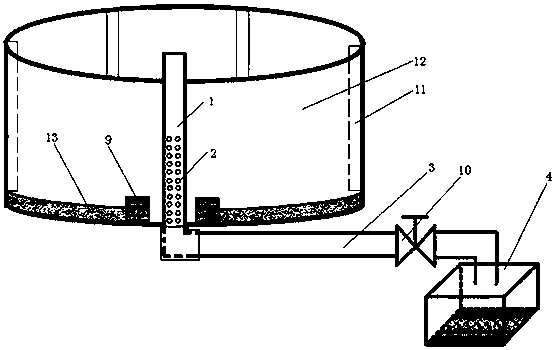

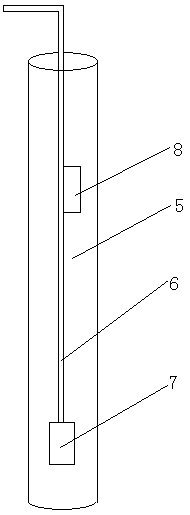

[0046] The industrialized large-scale seed cultivation device of Penaeus japonicus of the present embodiment, refer to the attached Figure 1-2 , including a plurality of cultivation ponds 12 located in the cultivation chamber. The cross section of the cultivation pond 12 is circular. The cultivation pond 12 is provided with temperature control, water supply and air supply devices. In the air-lift device 11 that inflates into the cultivation pond 12 and can drive the pool water to rotate and flow, a drainage standpipe 1 is installed at the drain outlet at the bottom of the cultivation pond 12, and a part of the pipe body of the drainage riser 1 near the bottom of the cultivation pond 12 is provided with drainage Hole 2, the bottom of drainage standpipe 1 is equipped with blowdown pipe 3, and one end of blowdown pipe 3 is inserted in the seedling collection groove 4; A circular sewage collection area is formed; the gas lift device 11 includes an outer tube 5 that is at the same...

Embodiment 2

[0048] The industrial large-scale seed cultivation method of Penaeus japonica in this embodiment comprises the following cultivation steps:

[0049] 1. Cultivation room and pool setting

[0050] Cultivation room area 600~1000m 2 , with a glass fiber reinforced plastic or plastic membrane roof, the roof shading rate reaches more than 80%, and the indoor light intensity is maintained at 500~1000lx;

[0051] The cultivation pool 12 is built indoors. The cultivation pool 12 is circular, with a diameter of 5m, a pool depth of 1.4m, and an effective water depth of 1.1-1.2m; the middle of the cultivation pool is drained, and the gradient from the bottom of the pool to the drain is 4-6%. Φ110cm pvc drainage riser 1; drainage riser 1 from the bottom to 50cm, every cm 2 Drill one Φ0.3cm drainage hole 2; the drainage standpipe 1 is connected to the sewage valve 10 outside the pool through the sewage pipeline 3 pre-buried at the bottom of the pool, and the length 100cm×width 80cm×is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com